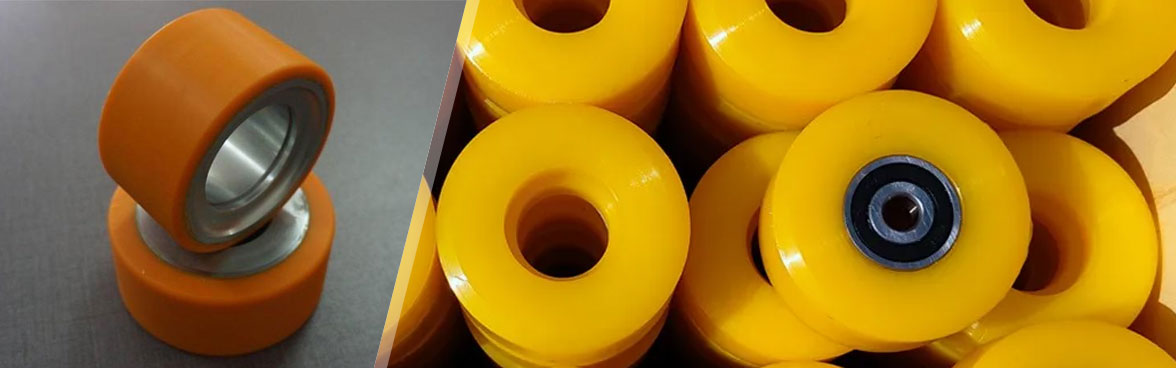

In underground and surface mining transportation systems, ropeway passenger systems (commonly known as monkey chair systems) play a critical role in ensuring the safe and efficient movement of personnel. Among their key wear components, polyurethane rope sheave liners directly affect system stability, service life, and overall maintenance costs.

However, many mining equipment manufacturers and component suppliers face a common production challenge:

How to consistently and efficiently mass-produce polyurethane rope sheave liners with high uniformity and superior wear resistance?

Production Pain Points in Traditional Manufacturing

Conventional manual casting or semi-automatic equipment often leads to:

- Excessive internal air bubbles

- Uneven density distribution

- Dimensional inaccuracies and poor repeatability

These defects compromise load-bearing capacity, vibration damping, and wear resistance, resulting in frequent liner replacement, unplanned downtime, and rising operational costs.

The challenge intensifies when different mining environments demand customized material properties, such as varying hardness levels, elastic modulus, oil resistance, and temperature resistance. General-purpose equipment lacks flexibility, leading to long trial cycles and high scrap rates.

Feilong’s Dedicated Polyurethane Elastomer Casting Solution

To address the strict performance requirements of rope sheave liners—components with relatively simple geometry but demanding mechanical properties—Feilong has developed a specialized polyurethane elastomer casting machine series with the following core advantages:

1. Precision Metering and Mixing System

High-accuracy servo-driven metering pumps combined with static or dynamic mixing heads ensure A/B ratio deviation within ±1%, eliminating curing defects and mechanical property fluctuations caused by inaccurate dosing.

2. Vacuum Degassing & Low-Pressure Casting Technology

By effectively removing entrapped air from raw materials and ensuring bubble-free mold filling, Feilong’s system significantly improves internal density, structural integrity, and surface finish of the liners.

3. Modular Temperature Control System

Independent temperature control for material tanks, pipelines, and molds allows precise adaptation to different polyurethane formulations (MDI or TDI systems), ensuring stable processing windows and excellent batch-to-batch consistency.

4. Fast Mold Change & Automation Integration

Standardized mold interfaces, combined with automated mold opening, closing, and demolding systems, enable seamless integration into production lines—supporting hundreds of units per shift with stable, repeatable output.

Beyond Equipment: Process Expertise That Delivers Certainty

At Feilong, equipment is only the carrier of value. The real objective is helping customers achieve maximum qualified product rates with minimum equipment downtime.

Backed by 54 patented technologies and decades of industry experience, Feilong provides comprehensive support for rope sheave liner manufacturers:

- Pre-sales process consultation: Simulation-based optimization of casting paths and parameters based on material properties, liner geometry, and operating conditions

- Customized development capabilities: Dedicated equipment design and pilot trials for special sizes, irregular geometries, or composite liner structures

- Full lifecycle service support: Installation, commissioning, operator training, and remote diagnostics to ensure long-term stable operation

Conclusion: Professional Equipment Means Production Certainty

As mining operations continue to advance toward greater intelligence and safety, the quality of critical components such as polyurethane rope sheave liners is no longer a “good enough” consideration—it is a decisive factor in system reliability.

Rather than absorbing hidden costs through repeated trial-and-error on inefficient equipment, manufacturers can secure long-term competitiveness by choosing professional polyurethane casting solutions designed specifically for mining applications.