Have you encountered these problems in hatch cover sealing strip production?

- The mold is just installed, material is poured—and you get bubbles or short shots.

- After finally stabilizing parameters, a new batch of raw material throws everything off again.

- Customers demand hardness tolerance of ±3 Shore A, but your production fluctuates within ±8.

- Even worse, month-end inventory reveals 15% scrap rate, with rework costs exceeding actual profit.

If hatch cover seal production has become a constant firefighting exercise, the root cause is often not your operators, not your formulation—but your equipment, which can no longer meet modern requirements for precision manufacturing.

An Outdated Casting Machine Is Quietly Undermining Your Competitiveness

Many manufacturers are still operating polyurethane casting machines designed ten or even twenty years ago. These machines may still be “running,” but they are far from stable, repeatable, or intelligent.

Typical limitations include:

- Mechanical gear metering: Wear leads to drifting ratios and unstable material properties.

- Manual mixing adjustments: Large performance variations between batches.

- Experience-based temperature control: Seasonal changes cause dramatic quality fluctuations.

- Reactive maintenance: When failures occur, downtime costs thousands per day.

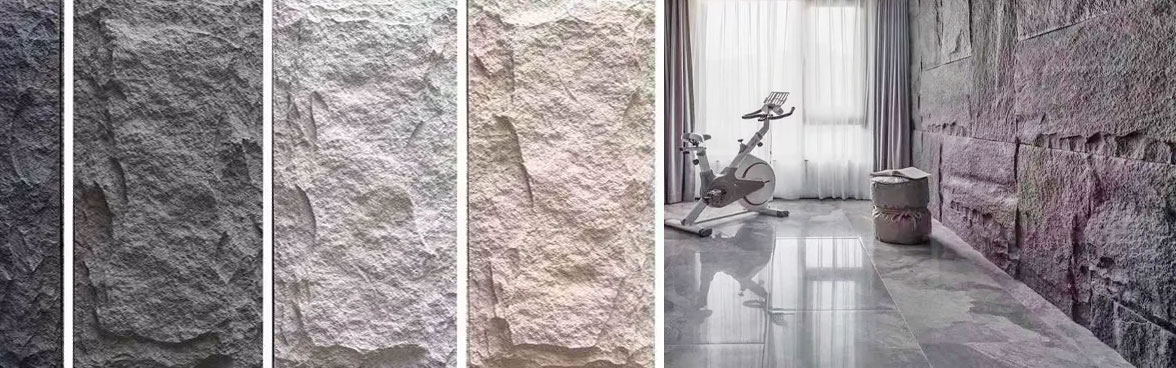

In industries such as marine engineering, rail transportation, and defense, where sealing failure is simply unacceptable, the cost of a single leakage incident can far exceed the investment in a modern casting system.

Feilong’s Answer: Not Just Selling Machines, but Eliminating Uncertainty

Feilong Polyurethane Equipment

For high-requirement products such as hatch cover sealing strips, Feilong takes a distinctly engineering-driven approach.

Process First, Equipment Second

Feilong does not start with a quotation.

The process comes first.

The technical team conducts a detailed analysis of:

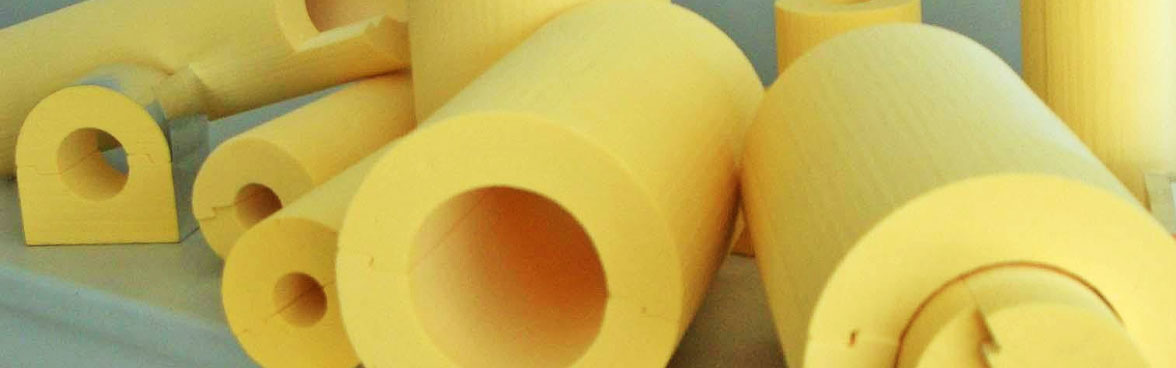

- Material system (MDI or TDI? prepolymer or one-shot process?)

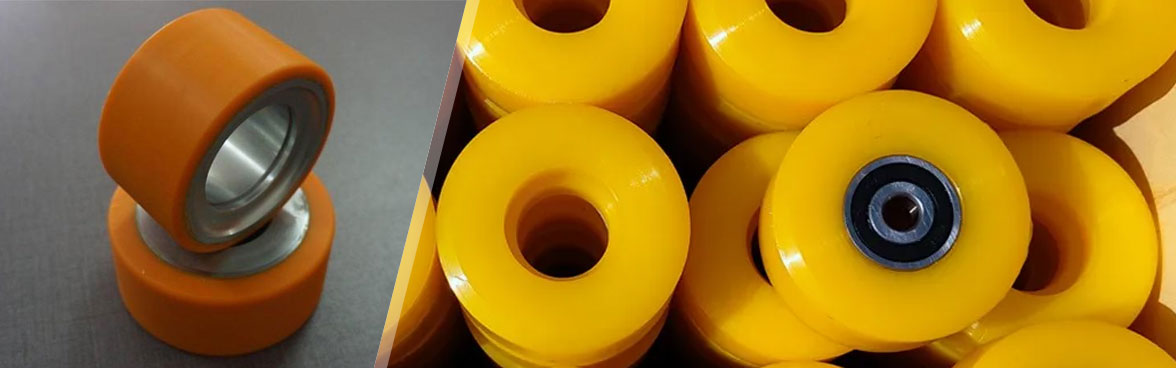

- Seal geometry and mold structure (length, cross-section, inserts)

- Production targets and cycle time requirements

Based on decades of application experience, Feilong identifies potential issues such as air entrapment, incomplete filling, pressure compensation, and proposes targeted process and equipment optimization before the machine is even configured.

From Operator-Dependent to Digitally Controlled

Feilong casting machines are equipped with high-precision servo-driven metering systems, ensuring stable and accurate A/B component ratios.

Key parameters—including temperature, pressure, and flow rate—are fully digitized, monitored in real time, and recorded for traceability.

This transforms production from experience-based control into data-driven repeatability, allowing consistent hardness and sealing performance batch after batch.

Reliability by Design, Not by Luck

The entire machine adopts a modular architecture. Critical components such as metering pumps and mixing heads support rapid disassembly and maintenance.

More importantly, every Feilong system undergoes full process validation and testing at the R&D center before shipment.

Problems are resolved in the factory—not on your shop floor.

What You Really Need Is a Machine That Understands Your Process

In an era defined by quality consistency, delivery reliability, and cost control, equipment should never be the most unpredictable part of your production chain.

Feilong does not aim to be the cheapest supplier.

Instead, Feilong strives to be the most reliable polyurethane equipment partner—especially for applications like hatch cover sealing strips, where the product may be small, but the responsibility is enormous.