Have you ever calculated how many polyurethane conveyor rollers in each production batch are scrapped—not because of material issues, but because the equipment simply can’t keep up?

How much downtime could have been avoided if your casting process were truly stable?

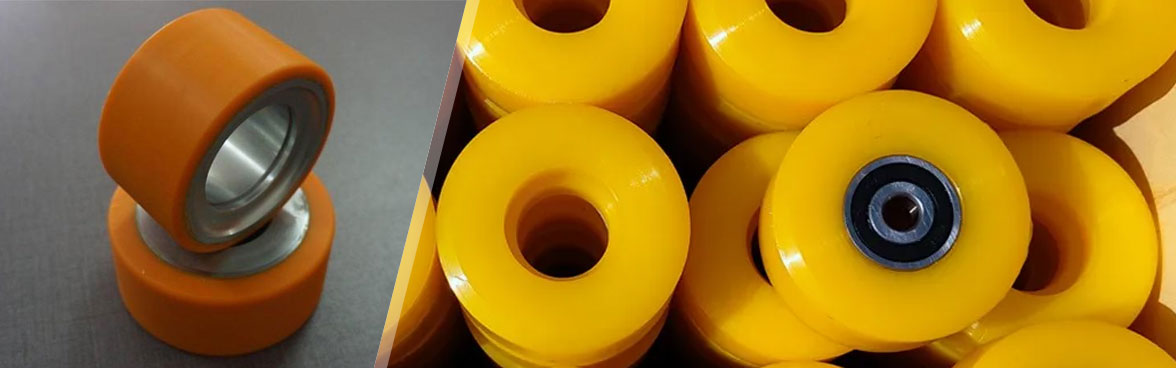

In mining, ports, and power plants—where conveyor reliability is non-negotiable—polyurethane conveyor rollers are no longer optional. Their abrasion resistance, low noise, corrosion resistance, and ability to extend belt life make them a standard choice.

But for manufacturers, the reality is far less comfortable:

- Tight delivery schedules

- Strict quality standards

- Near-zero tolerance for batch variation

Internally, production teams are often held back by unstable yield rates and equipment that fails at critical moments.

So the real question is not just about formulation or operator skill:

Is your polyurethane casting machine truly designed for conveyor roller production?

Feilong’s Answer Is Direct:

The problem isn’t your process—it’s your equipment.

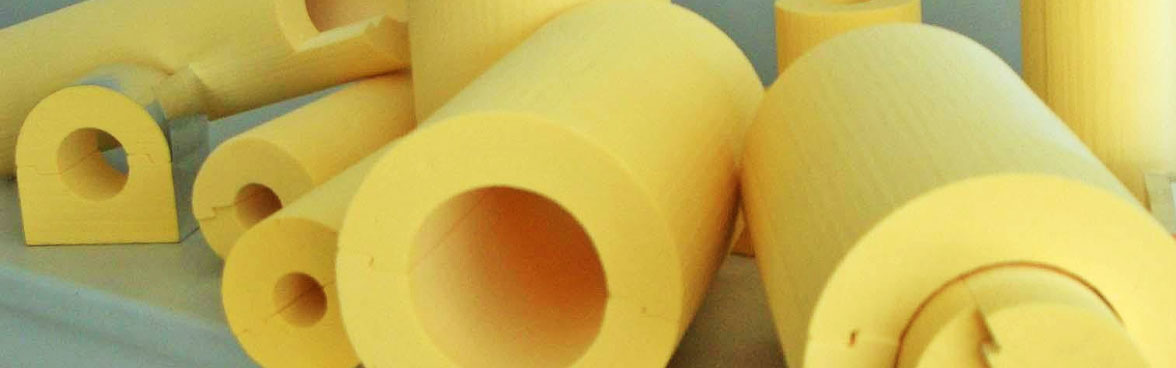

Conveyor rollers are not parts you can “just make.”

They must be consistent, repeatable, and reliable—every single unit.

That’s why Feilong treats its polyurethane casting machines not as simple dispensers, but as precision chemical reaction platforms, engineered specifically for elastomer applications like conveyor rollers.

The “Hidden Barriers” in Conveyor Roller Production

What looks like a simple cylindrical component actually places strict, often underestimated demands on equipment performance:

Inaccurate Mixing

→ Surface bubbles, porous cores, premature cracking after installation.

Temperature Drift

→ Seasonal hardness deviations of up to 10 Shore A, leading to customer rejection.

Complex Cleaning & Material Changeover

→ Two hours of downtime per material switch, locking your line into a productivity bottleneck.

How Feilong Solves These Problems at the Equipment Level

✔ High-Precision Servo Metering with Closed-Loop Feedback

Feilong adopts servo-driven metering pumps combined with closed-loop control, ensuring a stable A/B ratio—the foundation of consistent rebound, hardness, and mechanical strength in high-performance PU roller systems.

✔ Independent Mold Zone Temperature Control + Casting Rhythm Synchronization

Even when ambient temperature fluctuates by 10 °C, the system maintains tight thermal stability, keeping roller performance variations well within customer acceptance limits.

✔ Full-Flow Quick-Release Design with Automated Solvent Flushing

Material changeovers are completed rapidly through fast-disconnect flow channels and automated cleaning programs, minimizing downtime and keeping production lines running.

Conclusion: Choosing Equipment Is Choosing a Long-Term Partner

Feilong Polyurethane Equipment focuses on one thing only:

Turning every drop of polyurethane raw material into a qualified conveyor roller—not wasted scrap in a disposal drum.

For manufacturers who are serious about reducing defects, stabilizing output, and protecting margins, the right casting machine is not a cost—it’s a strategic asset.