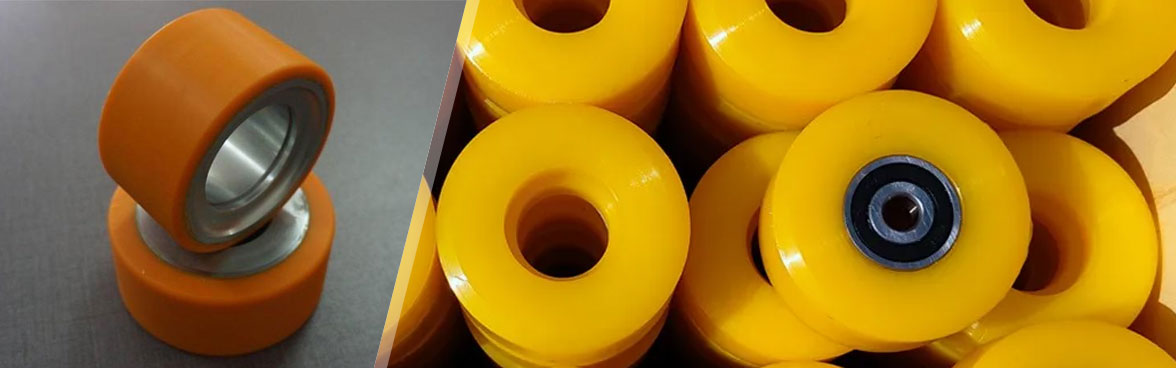

In the highly regulated and precision-driven world of medical devices, every detail matters. Behind the smooth operation of hospital beds, imaging systems, infusion stands, and mobile diagnostic equipment lies a seemingly modest component that carries enormous responsibility—custom polyurethane (PU) shock-absorbing caster wheels.

These wheels do far more than support weight. They must ensure ultra-quiet movement, protect sensitive internal components from vibration, withstand aggressive hospital disinfection protocols, and maintain long-term structural integrity without degradation. For manufacturers of high-end medical equipment, delivering such performance consistently is a formidable manufacturing challenge.

From “General-Purpose” to “Medical-Grade”: The Manufacturing Bottleneck

Unlike conventional industrial casters, medical-grade PU-coated wheels operate under a distinct and far more demanding set of requirements:

- Ultra-low noise and superior shock absorption In ICUs and patient wards, silence is not a luxury but a necessity. Wheels must exhibit excellent elasticity and damping performance to minimize vibration and prevent damage to precision medical instruments.

- Exceptional chemical resistance Continuous exposure to alcohol-based cleaners, chlorine-containing disinfectants, and UV sterilization can cause inferior polyurethane to yellow, embrittle, crack, or delaminate.

- Hygienic, non-porous surfaces Dense, closed-cell structures are essential to prevent bacterial growth and enable rapid, thorough cleaning.

Many manufacturers struggle to meet these standards due to inherent limitations in traditional polyurethane casting equipment. Common issues include incomplete mixing that leads to internal micro-bubbles, inconsistent A/B ratio control causing unstable mechanical properties, and poor handling of high-hardness formulations or functional fillers. Ultimately, the root problem is the absence of a manufacturing system capable of precisely reproducing medical-grade PU formulations at scale.

Feilong: Engineering Solutions for Medical-Grade PU Wheels

As a National High-Tech Enterprise and Chairman Unit of the Equipment Committee of the China Polyurethane Industry Association, Feilong Polyurethane Equipment is not merely a machinery supplier—it is a comprehensive process solution provider with deep expertise in material science and application engineering.

To address the unique demands of medical mobility components, Feilong has developed advanced polyurethane elastomer casting machines and polymer composite processing systems that overcome key industry bottlenecks through proprietary technologies.

1. Precision Control That Eliminates “Hidden Defects”

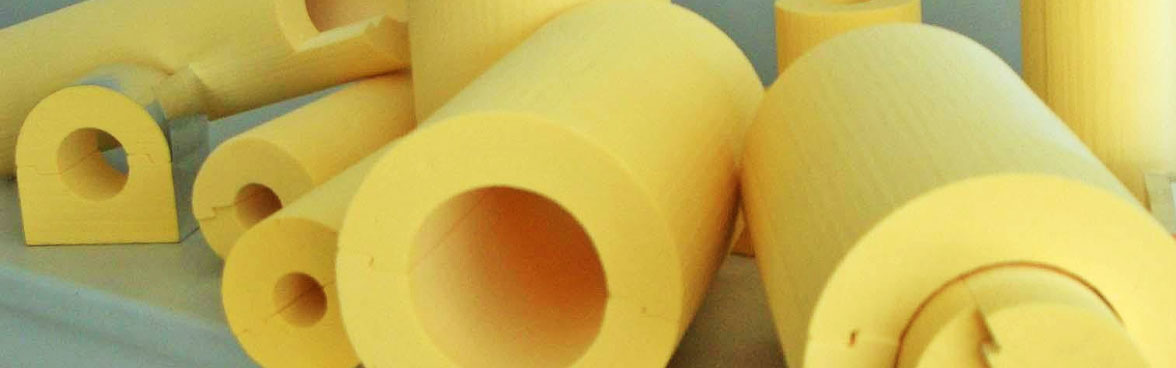

Internal voids or delamination are unacceptable in medical caster wheels, as they can lead to sudden failure under load. Feilong’s equipment integrates high-precision mixing head technology with dynamic ratio control systems, ensuring exceptionally stable and uniform blending of A and B components during casting.

This precision enables homogeneous material structure at a microscopic level, effectively eliminating entrapped air and ensuring dense, defect-free PU wheels with reliable mechanical performance.

2. Breakthrough Processing of High-Hardness Fillers for Superior Bonding

To meet the durability demands of hospital flooring, high-end medical wheels often require modified formulations incorporating wear-resistant fillers or high-hardness elastomers. Feilong’s patented solutions specifically address filler dispersion challenges under high-viscosity conditions, preventing sedimentation and uneven distribution.

The result is a smooth, wear-resistant surface combined with exceptionally strong interfacial bonding between the polyurethane layer and the metal wheel core—significantly reducing the risk of delamination over long-term use.

3. Intelligent, Customized Systems for Diverse Production Needs

Medical equipment ranges from lightweight IV stands to heavy CT and MRI systems, each requiring wheels with different sizes, load ratings, and performance profiles. Feilong offers a full spectrum of equipment—from micro-flow precision systems to large-capacity casting machines—and provides tailored configurations based on plant layout, production volume, and formulation requirements.

Beyond equipment delivery, Feilong supports customers throughout the entire lifecycle, helping them translate stringent medical standards into stable, repeatable manufacturing processes.

Conclusion

In medical mobility solutions, polyurethane shock-absorbing caster wheels may be small, but their impact on safety, durability, and user experience is substantial. Through decades of expertise and continuous innovation in polyurethane equipment, Feilong is empowering manufacturers to overcome technical barriers and transform demanding requirements for silence, hygiene, and reliability into high-quality, market-ready medical components.