As the global fitness boom accelerates, every dumbbell, treadmill, and training machine in modern gyms reflects consumers’ rising expectations for quality, durability, and performance. Beneath this expanding market, however, many manufacturers face persistent bottlenecks:

How can complex aesthetics coexist with stable and repeatable mechanical performance?

How can higher yield rates be converted into real, sustainable profit in an increasingly competitive market?

Feilong Polyurethane Equipment, a National High-Tech Enterprise and a Provincial “Specialized, Refined, Distinctive and Innovative” SME, offers a distinctly Chinese answer built on more than two decades of engineering expertise—enhancing quality through intelligence, shaping form through technology.

Beyond Machine Building: Defining Industry Standards

Feilong understands that each generation of fitness equipment places more stringent demands on material molding and process control. Led by a dedicated polyurethane expert team, Feilong integrates chemical engineering, mechanical design, electrical systems, and computerized control into a unified technology platform.

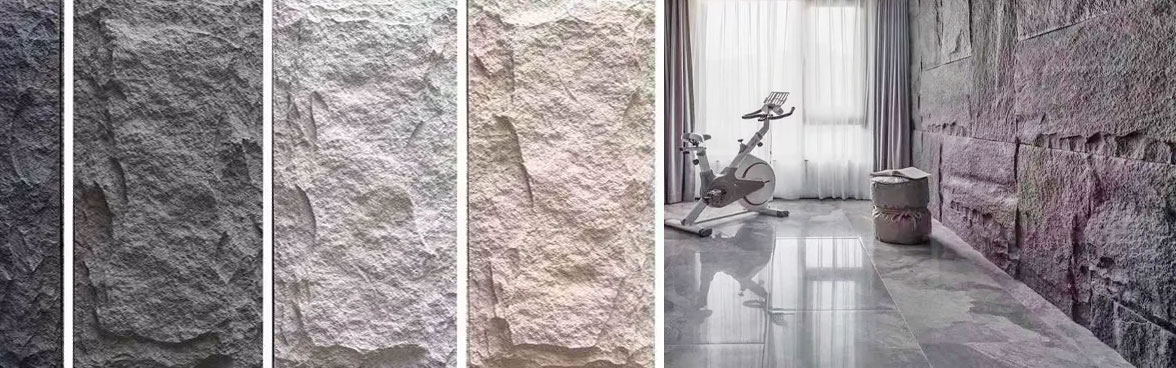

Rather than supplying generic equipment, Feilong excels at computer-simulated process optimization and customized turnkey solutions tailored to complex fitness equipment structures.

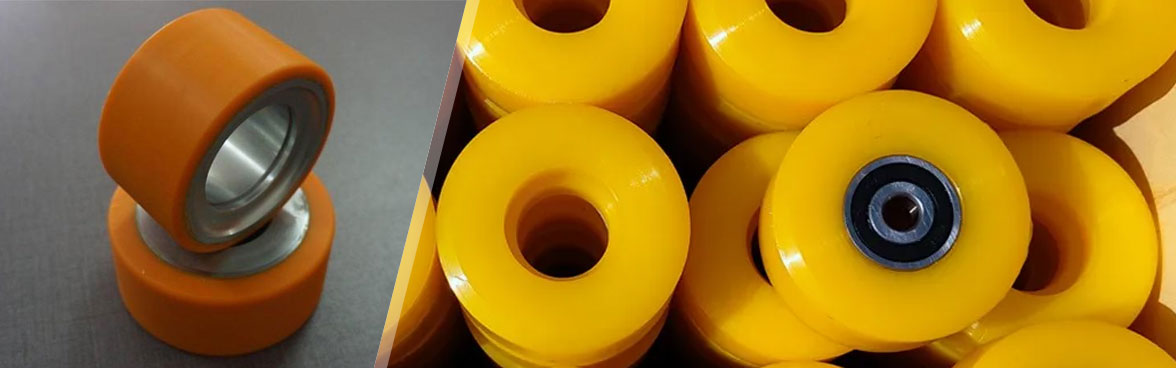

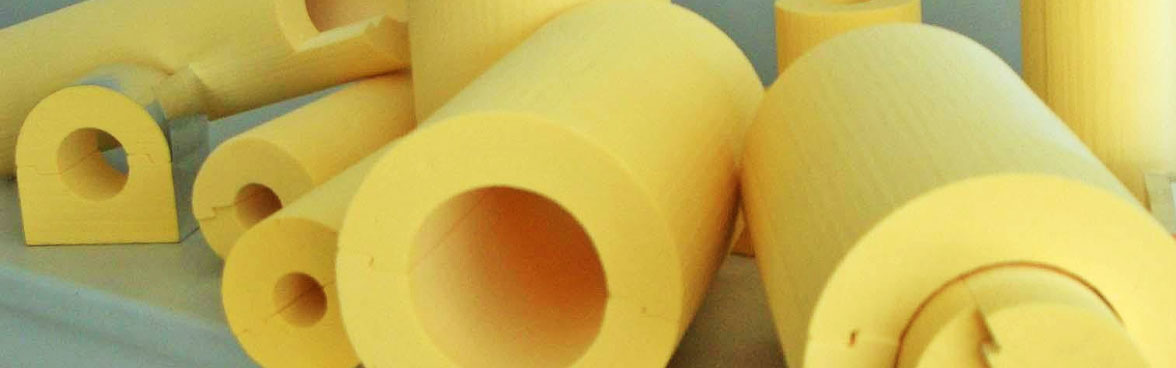

From flawless filling of irregular geometries to ultra-precise multi-component ratio control, Feilong systems ensure that every drop of material is delivered exactly where and how it is required.

This uncompromising respect for process precision significantly boosts product yield rates while minimizing equipment downtime—allowing “Made in China” to benchmark itself against the world’s most advanced manufacturing standards.

A Patent-Driven Moat: Turning Pain Points into Competitive Advantages

In polyurethane molding, defects such as air bubbles, shrinkage, and poor mixing have long plagued manufacturers. Feilong’s R&D philosophy is straightforward: confront pain points head-on and eliminate them through proprietary technology.

Backed by multiple national patents and extensive participation in provincial and municipal R&D programs, Feilong has developed deep expertise in Reaction Injection Molding (RIM) technologies. Its core equipment adapts seamlessly to specialized process requirements while leveraging intelligent control systems to monitor and dynamically adjust temperature, pressure, and mixing ratios in real time.

For fitness equipment manufacturers, this means more than acquiring a machine—it means gaining access to a proven, production-ready process ecosystem. Whether producing ergonomically optimized grips or high-load structural components, Feilong equipment empowers customers to accelerate product development and secure first-mover advantages in the market.

Conclusion: Choosing Feilong Means Choosing Worry-Free Manufacturing

In the fast-growing polyurethane fitness equipment sector, Feilong is not merely an equipment supplier—it is a long-term partner in cost reduction, efficiency improvement, and quality assurance.

If you aim to eliminate yield-rate anxiety and upgrade your production line toward true intelligent manufacturing, Feilong invites you to join a new era of precision-driven, efficiency-focused polyurethane production—where quality and performance advance together.