More and more manufacturers of polyurethane (PU) stone veneer are beginning to face a hard truth:

it is not the market that is failing—it is the equipment that can no longer keep up.

That old machine may have supported you during the early days, helped you secure your first orders, and carried you through difficult years. But today:

- Every color change requires 30 minutes of manual cleaning

- Coating thickness still depends on an operator’s “feel”

- Mixing ratios drift uncontrollably during hot summer conditions

- When a client requests curved or customized stone panels, the only answer is: “Our machine can’t do that.”

If any of this sounds familiar, the following may be worth your time.

Feilong’s Answer: Solving Process Problems with Engineering Thinking

Since its establishment, Feilong Polyurethane Equipment has focused on one core objective:

to elevate PU equipment from “usable” to “reliable”, and ultimately to “intelligent and process-driven.”

Their philosophy is straightforward:

Customers do not need a machine—they need a system that consistently produces qualified products.

To achieve this, Feilong’s engineers work directly inside customer factories, identifying real production bottlenecks:

- Micro-bubbles after A/B mixing? → Development of high-pressure mixing head technology

- Low efficiency for small-batch, multi-color production? → Quick-change mold interfaces and automatic cleaning modules

- High error rates with new operators? → Touchscreen-guided operation with locked process parameters

These engineering decisions have resulted in 30+ national patents, ISO 9001 certification, and EU CE compliance—not as marketing symbols, but as guarantees of reduced errors and stable output in real production environments.

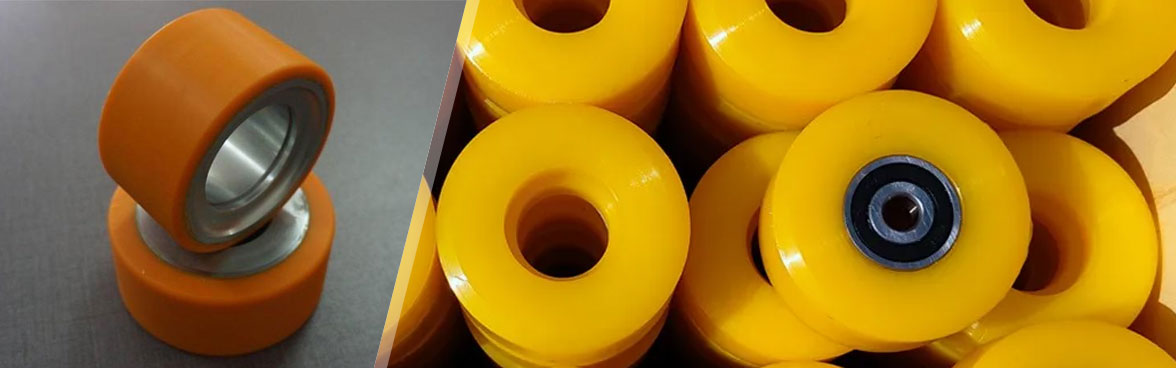

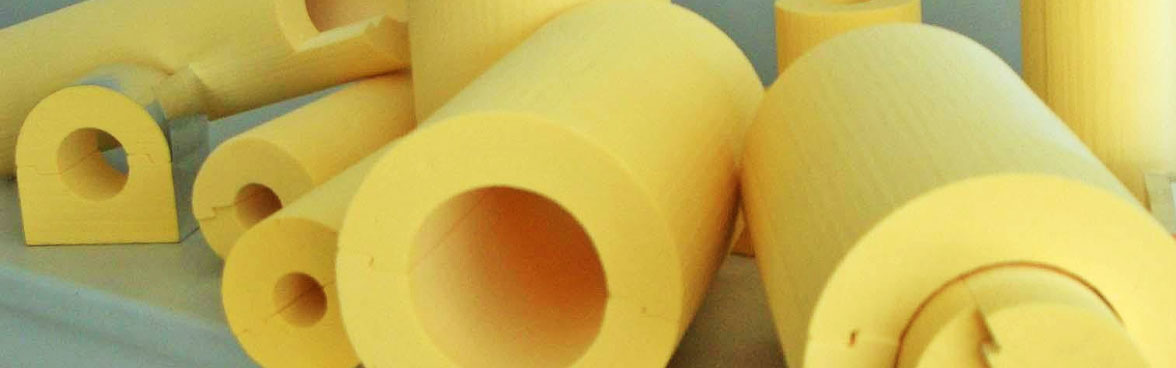

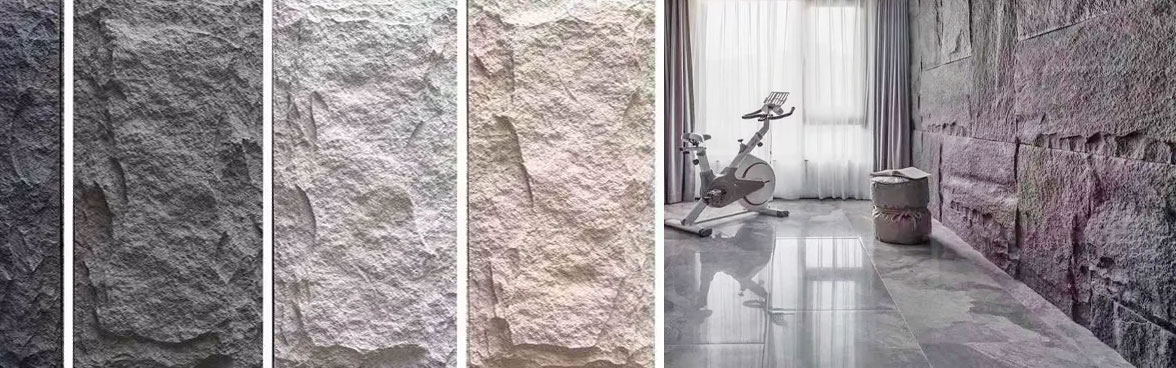

PU Stone Veneer Is, at Its Core, the Art of Precision Casting

Do not be misled by the word “imitation.”

High-quality PU stone veneer demands:

- Natural stone-like cracks and textures on the surface

- Dense, bubble-free internal structure

- Sharp, clean edges without burrs

Achieving this requires the precise coordination of temperature, pressure, flow rate, and time.

Traditional equipment relies on manual valve adjustments and visual judgment—highly variable and difficult to replicate. Feilong’s systems replace uncertainty with control:

- Servo-driven metering systems for high-precision dosing

- Integrated temperature control to stabilize raw materials

- Flexible support for diversified product customization

- Intelligent operating interfaces that significantly reduce skill dependency

The result: expert craftsmanship becomes embedded in software. New operators can produce consistent quality, and complex textures—such as Venetian limestone patterns—can be reproduced with confidence.

Not Every Equipment Supplier Dares to Say: “We Build to Your Process”

Many manufacturers sell standardized machines. Any modification means higher costs and longer delivery times.

From day one, Feilong positioned itself as a polyurethane process equipment solution provider, not a standard machine vendor.

Its portfolio includes:

- Extra-wide continuous casting lines

- Multi-color gradient synchronous pouring systems (including 10-color PU casting machines)

- Highly specialized non-standard customized equipment

This capability is backed by full in-house expertise in mechanical design, fluid simulation, electrical control, and software development—from concept and drawings to commissioning and optimization.

More importantly, Feilong intervenes early in the project lifecycle. Technical feasibility is validated before production begins, ensuring risks are eliminated upfront rather than discovered through scrap and rework.

Conclusion: Choosing Equipment Means Choosing Your Future Production Model

Upgrading equipment is not a cost—it is an investment in certainty.

Stable, intelligent, and customizable systems deliver higher yield rates, predictable delivery, and long-term competitiveness.

In the end, the right equipment does not just improve production.

It gives you control over quality, timelines, and ultimately, pricing power in the market.