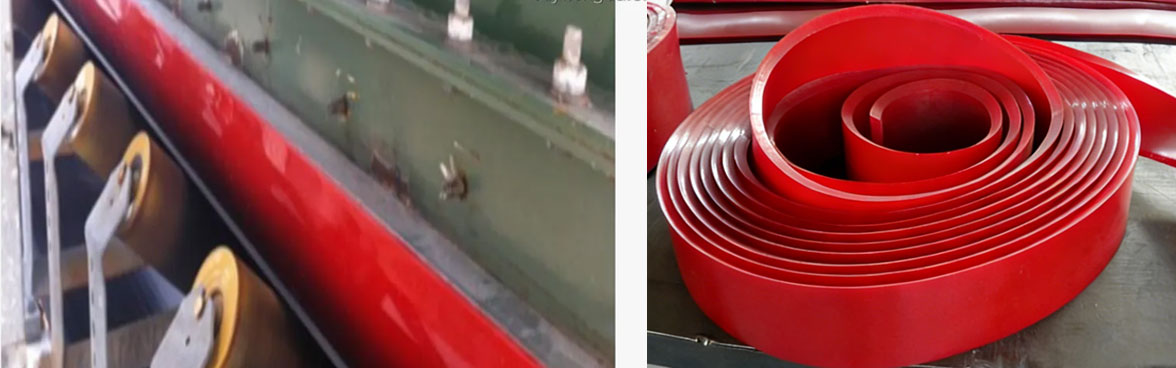

In mining, ports, power plants, and other heavy-duty industrial environments, conveyor systems are the “main arteries” of bulk material handling. As one of the most critical protective components, polyurethane conveyor skirting boards—also known as side seals, chute liners, or material guides—are continuously exposed to high-impact and highly abrasive materials such as ore, coal, and aggregates.

Under long-term operation, skirting boards are prone to abrasion, cracking, deformation, and delamination. Once failure occurs, the consequences extend far beyond material spillage: reduced conveying efficiency, unplanned downtime, safety hazards, and sharply increased maintenance costs.

For mining equipment manufacturers and wear-part producers, a persistent challenge remains:

How can polyurethane skirting boards be produced efficiently and consistently with high hardness, strong elasticity, excellent metal adhesion, and precise dimensional accuracy?

Traditional Manufacturing Bottlenecks

Conventional manual or semi-automatic polyurethane casting processes often suffer from:

- Inconsistent A/B material mixing

- Entrapped air bubbles and internal voids

- Unstable curing behavior

- Poor batch-to-batch repeatability

These issues directly result in low yield rates, frequent rework, and shortened service life, making it difficult to meet modern mining operations’ demand for long-lasting, high-reliability wear components.

Feilong’s Intelligent Polyurethane Casting Solution for Mining Skirting Boards

To address the specific performance requirements of mining-grade polyurethane skirting boards—such as Shore hardness above 85A, high tear resistance, strong bonding to steel backplates, and complex profile molding—Feilong Polyurethane Equipment has developed dedicated polyurethane elastomer casting machines and integrated production lines with the following core advantages:

1. Precision Metering & High-Efficiency Mixing for Consistent Performance

Feilong systems utilize high-accuracy servo-driven metering units, controlling A/B component ratio deviations within ±1%. Combined with proprietary static or dynamic mixing heads, the system ensures complete and uniform reactions between polyols and isocyanates.

This eliminates localized soft spots or brittleness caused by poor mixing, significantly improving mechanical property consistency across the entire skirting board.

2. Vacuum Degassing & Pressure Casting to Eliminate Internal Defects

For thick-wall or geometrically complex skirting board molds, Feilong integrates vacuum degassing before casting, effectively removing entrained air from raw materials.

During casting, controlled pressure injection ensures full mold filling, even in blind corners, dramatically reducing air pockets, shrinkage cavities, and internal porosity—key factors in extending service life under abrasive conditions.

3. Modular Temperature Control Adapted to Multiple Formulations

Different mining applications require different polyurethane systems, including MDI-based, TDI-based, or formulations with wear-resistant fillers.

Feilong equipment features independent zoned temperature control for raw material tanks, pipelines, mixing heads, and molds. This precise thermal management allows each formulation to operate within its optimal reaction window, ensuring stable curing and repeatable quality.

4. Integrated Metal Insert Preheating & Positioning for Superior Bonding

Most polyurethane skirting boards are reinforced with steel backing plates. Feilong production lines can integrate automatic metal insert preheating and online positioning systems, ensuring optimal interface temperature during casting.

This significantly enhances polyurethane-to-metal adhesion strength, preventing delamination or debonding during long-term operation.

5. Flexible Production Lines for Customization and Scale

Whether producing single prototypes, small-batch customized profiles, or large-volume standardized skirting boards, Feilong offers scalable solutions ranging from manual and semi-automatic setups to fully automated production lines.

Quick-change mold systems and digital recipe storage enable one-click process parameter recall, minimizing changeover time and maximizing equipment utilization.

Beyond Equipment: A Manufacturing Partner Who Understands Polyurethane

At Feilong, equipment is not the end goal—it is a means to help customers manufacture qualified, reliable, and competitive products.

In today’s highly competitive mining spare-parts market, product durability and delivery stability have become decisive advantages. Instead of repeatedly troubleshooting inefficient equipment, partnering with an equipment supplier that truly understands polyurethane chemistry, processing technology, and mining industry pain points is the smarter long-term strategy.