When choosing a sofa, we instinctively touch the leather surface—the soft, delicate feel can instantly create a sense of comfort, while stiffness or roughness is an instant turn-off. This “first touch” experience comes down to the core technology behind sofa leather production. As consumers shift from simply wanting “usable” furniture to demanding “comfort and durability,” traditional sofa leather manufacturing faces mounting challenges such as solvent pollution, inconsistent texture, and poor abrasion resistance.

Feilong’s new eco-friendly polyurethane foam equipment is leading a material technology revolution that is setting new industry standards. This equipment eliminates solvent-based processes to address environmental concerns while delivering precise foam control that transforms sofa leather from a “rigid plastic feel” to a “soft, cloud-like touch.” Whether you are an industry professional or a consumer, understanding this technology reveals how it’s changing the materials we interact with every day.

Three Core Innovations: Why Sofa Leather Feels Different

1. 0.5% Precision Control: The “Micro-Architect” of Foam Cells

The internal foam structure of sofa leather acts like countless tiny springs. Their size, distribution, and elasticity directly determine the tactile experience. Traditional machines with ±5% dosing errors often create uneven foam, resulting in “hard spots” or “collapse zones.”

Feilong’s polyurethane equipment uses a high-precision gear pump system to keep dosing error within ≤0.5%—equivalent to adding just 5ml of material to 1,000ml of liquid. Combined with ±2°C temperature accuracy, the system ensures a stable chemical reaction without scorching or freezing, producing uniform foam cells of 50–100μm. This size mimics the elasticity of natural leather, offering both support and a gentle rebound—like the soft resilience of fresh-baked bread.

2. Solvent-Free Foaming: From “Chemical Odors” to “Green Production”

Traditional sofa leather manufacturing heavily relies on solvents like DMF, filling workshops with pungent odors and VOC emissions (up to 1.2mg/m³). Feilong’s solvent-free process eliminates this dependency by reacting prepolymer materials directly, reducing VOC emissions to ≤0.5mg/m³, fully meeting safety standards.

This breakthrough creates a cleaner, safer production environment and ensures zero formaldehyde residue in the final product. Consumers with children, pregnant women, or allergy concerns can enjoy leather sofas without worrying about harmful emissions or odors.

3. Intelligent Formula Library: 100+ Touch Options for Customized Comfort

Different households have different tactile needs: families with kids want scratch resistance, young buyers prefer soft and bouncy textures, and seniors value firm support.

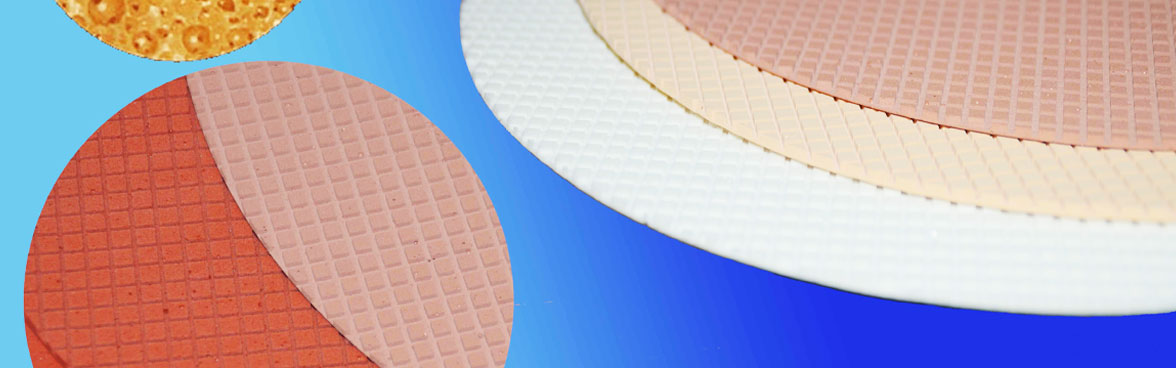

Feilong’s PLC-controlled intelligent system stores 100+ formulas. By adjusting output rate (16–2000g/s) and density gradients, it can produce sofa leather from 0.5mm to 20mm thick. For example, high-end brands often use a three-layer composite structure:

- Top layer (35kg/m³): High-density foam for abrasion resistance

- Middle layer (25kg/m³): Soft foam for plush comfort

- Bottom layer: Dense support layer to prevent sagging

This smart combination ensures sofas maintain their premium feel even after 10 years of use.

From Lab to Production Line: A Quality Revolution in Synthetic Leather

Lab tests show that conventional sofa leather tears after 300 friction cycles, whereas Feilong’s polyurethane technology withstands 3,000 cycles with only minor wear—10 times more durable.

Factories using Feilong’s equipment report:

- Yield rate: Increased from 85% to 98%

- Material savings: Up to ¥2 million annually

- Eco-compliance: Enables entry into premium supply chains

- Product premium: +30% market value

- Customer complaints: Down by 42%

Final Thoughts

When we sink into a sofa to relax, we rarely think about the science behind its softness. But innovations like Feilong’s eco-friendly polyurethane foam equipment make manufacturing greener and comfort more refined. From ±0.5% precision in the lab to luxurious softness in your living room, technology is quietly shaping a better everyday experience.