With global timber shortages and stricter environmental regulations, the construction and furniture industries face an urgent demand for “plastic replacing wood.” The Industrial Green Development Plan emphasizes promoting bio-based and low-carbon materials to replace traditional high-carbon materials. Polyurethane imitation wood technology has emerged as an industry favorite, offering both natural wood grain aesthetics and eco-friendly properties.

Feilong Polyurethane Equipment has developed an advanced high- and low-pressure foaming production line with key advantages such as ±1% ratio accuracy and 40% lower VOC emissions, setting new standards in imitation wood manufacturing and supporting the green building materials industry.

I. Technical Principles: Three Key Innovations in Feilong’s Production Line

As a National RIM (Reaction Injection Molding) Technology Sub-Center, Feilong integrates three core innovations into its foaming production line:

1. Precise Material Ratio Control

Equipped with a PLC control system and A2VK professional metering pumps, the system achieves ±0.5% accuracy in mix ratio adjustment.

For imitation wood molding, Component A (polyols) and Component B (isocyanates) are mixed at 1:1.05. With 12-component elastomer equipment, pigments, flame retardants, and other additives are accurately injected, ensuring density stability at 200–600 kg/m³.

2. High- and Low-Pressure Foaming Process

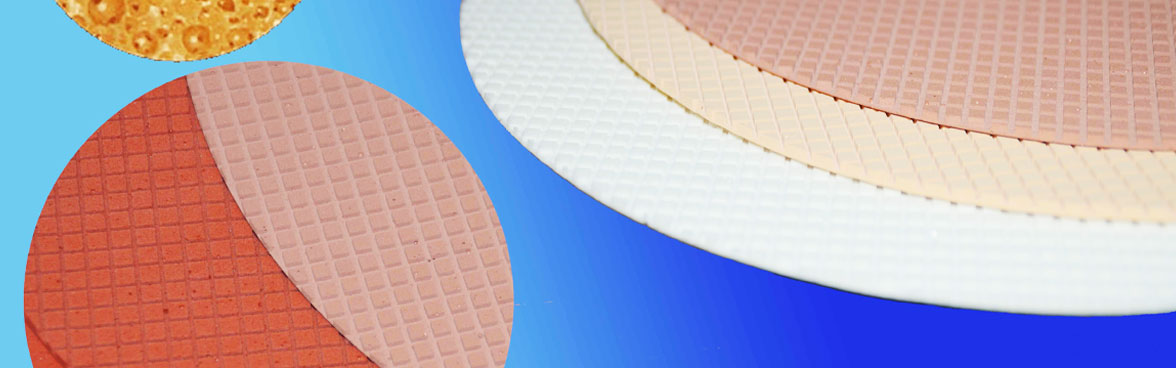

- Low-Pressure Foaming: Ideal for intricate moldings. Materials are injected at 2.5 MPa, with a 120-second holding time, delivering surface texture clarity up to 400 dpi.

- High-Pressure Foaming: Designed for structural components. With 8–13 MPa ultra-high-pressure mixing, material diffusion speed is 5× faster than conventional methods, achieving compressive strength ≥50 MPa, meeting structural load requirements.

3. Mold Adaptability Breakthrough

A quick-change mold system reduces mold changeover time from 2 hours to 10 minutes and supports over 3,000 decorative patterns.

For example, European-style carved moldings are replicated via 3D scanning of natural wood textures, improving product pass rate from 85% to 99.3%.

II. Full-Process Optimization: From Raw Materials to Finished Products

Taking decorative polyurethane moldings as an example:

- Raw Material Pretreatment Uses CFC-free polyether formulations, moisture content <0.1%, preheated in 120°C constant-temperature tanks, viscosity kept below 2000 CPS to prevent bubbles.

- Foaming and Molding Raw materials injected using high-pressure mixing heads (lifespan ≥300,000 cycles), combined with L-shaped flow channels for pressure buffering, ensuring curvature error <0.5°.

- Post-Processing Products cured at 60°C for 48 hours, surface coated with UV finish, achieving Grade 0 adhesion (GB/T 9286). Weather resistance testing shows outdoor lifespan >10 years.

III. Performance Comparison: Polyurethane vs. Traditional Materials

| Indicator | Polyurethane (Feilong) | Solid Wood | Gypsum |

|---|---|---|---|

| Density (kg/m³) | 200–600 | 500–800 | 800–1200 |

| Water Absorption (%) | <1 | 12–15 | 20–25 |

| Flexural Strength (MPa) | ≥30 | 15–20 | 5–8 |

| Installation Efficiency | 100 m/person·day | 30 m/person·day | 50 m/person·day |

Eco-advantage: B2 fire resistance certification, zero toxic gas emission during combustion, VOC emissions 1/20 of oil-based coatings, compliant with Green Building Evaluation Standard (GB/T 50378-2019).

IV. Market Outlook

- Applications: Beyond architecture, polyurethane imitation wood is expanding into cold-chain logistics (insulated boxes) and automotive interiors (steering wheels).

- Future Trends: Integration with 3D-printed molds and AI-driven formula optimization.

Conclusion

The Feilong high- and low-pressure foaming production line delivers material innovation, process upgrades, and green manufacturing, redefining the standards for imitation wood products. In line with China’s dual-carbon goals, this technology reduces overall costs by 30% while transforming the industry from resource-dependent to technology-driven.