As global agriculture shifts toward precision and sustainability, the fertilizer industry is undergoing a critical transition from quantity-driven growth to quality-focused efficiency. Among the breakthroughs in fertilizer slow-release technologies, polyurethane-coated controlled-release fertilizer is emerging as a “golden key” to solving the inefficiency and waste of traditional fertilizers. With precise nutrient release and eco-friendly performance, it is reshaping agricultural production models worldwide.

Technical Principle: From “Broad Supply” to “Precision Delivery”

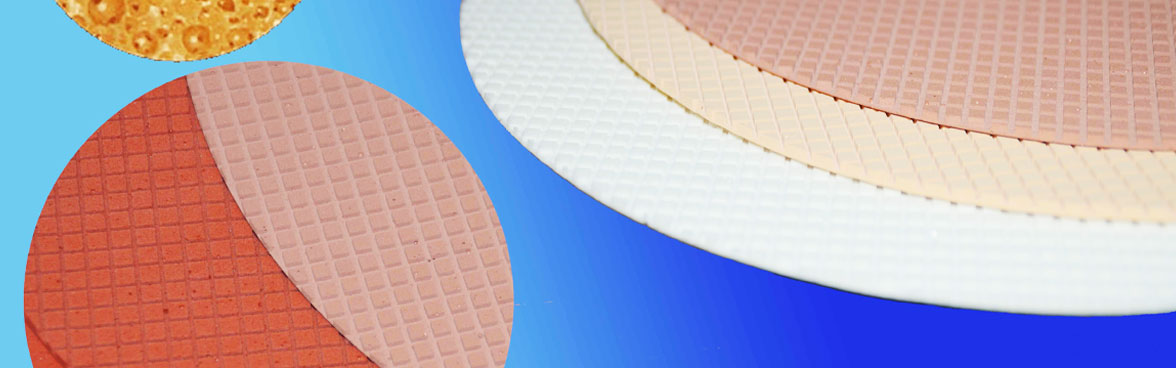

Micron-Level Breakthrough in Material Science

Feilong’s polyurethane coating technology reduces fertilizer coating thickness from the millimeter to the micron scale. Using nano-porous regulation, coating thickness is precisely controlled within the 0.1–0.3 mm golden range. Feilong’s intelligent production lines achieve a 98.7% uniformity rate, ensuring every granule has a tailored coating. With coating error margins narrowed from ±0.5 mm to ±0.02 mm, nutrient release cycles can precisely match crop growth stages—unlocking large-scale efficiency gains with micron-level precision.

“Smart Breathing Valve” Environmental Response

Nano-scale pores on the coating adjust with changes in temperature and humidity, acting like a dynamic breathing valve: releasing more nutrients during summer’s rapid growth (up to 30% faster) and slowing release during winter dormancy. This adaptive mechanism achieves over 90% synchronization with crop root development, delivering nutrients exactly when plants need them.

Technical Advantages: Cost Breakthroughs and Data-Driven Farming

Cost Revolution in Large-Scale Applications

Over the past decade, Feilong’s intelligent production lines achieved a dual breakthrough: annual capacity per line reaching 50,000 tons while production costs dropped by 60%. Once considered a “luxury fertilizer,” polyurethane-coated fertilizers have become accessible for mass agricultural use—proving that green technology becomes viable once it crosses the cost threshold.

From Experience-Based to Data-Driven Fertilization

By analyzing soil moisture and crop varieties, Feilong enables customized coating thickness and pore density for “one field, one strategy.” Trials show a 20% reduction in pesticide use, creating an eco-loop of less fertilizer, fewer chemicals, better yields, and higher efficiency. This marks a paradigm shift from experience-driven farming to data-driven agriculture.

Environmental Benefits: From Carbon Source to Carbon Sink

Polyurethane’s Contribution to Low-Carbon Agriculture

The controlled nutrient release mechanism reduces ammonia volatilization by 60% and nitrate leaching by 40%, cutting carbon emission intensity by 25% per crop season. For corn, applying 50 kg of Feilong’s polyurethane-coated fertilizer per acre reduces emissions by 12 kg of CO₂—equivalent to the annual carbon capture of three fir trees. Agriculture is transforming from a carbon burden into a low-carbon contributor.

Ecological Filter for Non-Point Source Pollution

By addressing pollution at the source, this technology reduces agricultural non-point pollution by 40% while improving soil organic matter by 1.2%. In wheat fields, ammonia emissions dropped by 60% and nitrate leaching by 40%, achieving dual benefits of pollution control and soil restoration. Farmland thus shifts from being a pollution contributor to an ecological buffer zone.

Conclusion: A Global Practice of Technology-Enabled Agriculture

The leap from millimeters to microns is more than a material upgrade—it is a fundamental reconfiguration of agricultural logic. With future innovations such as light-responsive and biodegradable coatings, polyurethane-controlled release fertilizers will continue to expand the boundaries of higher yields, farmer incomes, and environmental sustainability. Feilong’s solution offers a “China model” for global sustainable agriculture.