In semiconductor chips with nanometer-scale circuit patterns and optical lenses requiring hair-level flatness, surface finishing precision has become the “invisible threshold” for product performance. Traditional sandpaper, with its short lifespan and low accuracy, has long restricted efficiency improvements in precision processing industries.

Feilong Polyurethane Equipment addresses this challenge through “abrasive embedding technology”—embedding diamond abrasives into a polyurethane matrix. This innovation extends the service life to 4–6 times that of traditional sandpaper. Combined with water-resistant characteristics, it enables three times longer continuous operation in automated production lines.

Traditional Sandpaper vs. Polyurethane Polishing Pads: Core Performance Comparison

- Service Life: Traditional sandpaper ≈ 200 uses/piece; Feilong polishing pad: 800–1,200 uses/piece

- Precision Control: Sandpaper ±5 μm fluctuation; Polyurethane pad: ±0.5 μm stability

- Environmental Resistance: Sandpaper is moisture-sensitive; polyurethane pad is acid/alkali-resistant and supports wet polishing

Product Advantages: Precision Through Material & Process Innovation

Feilong applies a three-dimensional logic chain—Material Formulation → Microstructure → Process Adaptation—to build differentiated technical advantages:

- Material Engineering Hardness gradient adjustment (Shore hardness 30–100, continuously adjustable) Functional additives: cerium oxide increases polishing speed by 30%, zirconia reduces surface roughness to Ra < 0.2 nm Environmental durability: <0.5% weight change after 24 hours in 10% HCl solution

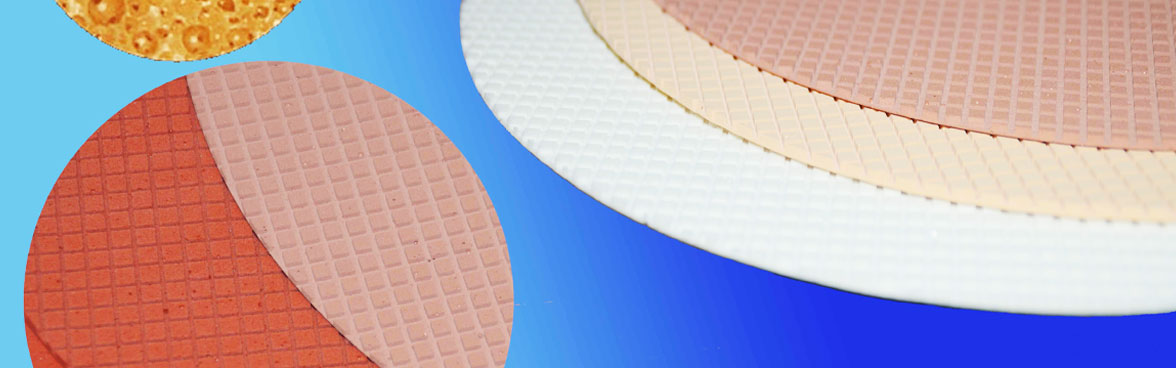

- Microstructure & Design Foam pore structure (20–50 μm) for better polishing slurry flow, improving processing speed by 40% Grooving (10P/15P/20P/30P) & perforation (2 mm multi-angle arrangement) for various applications Sandwich structure (elastic polyurethane foam + aluminum core) achieves dynamic balance accuracy of 0.002 mm, eliminating eccentric vibration during high-speed rotation

Technical Highlights

- Abrasive retention solution: Diamond abrasives embedded in polyurethane extend life up to 6× traditional sandpaper

- Full-process adaptability: Grit size 60–5000 mesh, hardness 30–95°, covering rough to fine polishing

- Environmental adaptability: Acid/alkali resistance, washable, reusable, 80% less wet-grinding dust

Core Patents: Building a Competitive Edge

Feilong’s key innovations focus on anti-clogging stability, precision metering, and smart automation:

- Anti-Clogging: Patented uniform mixing injection system with high-speed rotary scrapers increases maintenance cycle by 50% and operating uptime to 98%

- Precision Metering Control Flow compensation & closed-loop control: Accuracy ±0.5‰ (vs. industry ±1%) Ratio dosing optimization: Synchronization error within 0.2% Dynamic pressure balance: Temperature-viscosity linkage ensures discharge stability error ≤ 0.5%

- Smart Features for Industry 4.0 Real-time monitoring & feedback (coating thickness deviation ≤ ±0.1 mm) Remote maintenance & parameter optimization (setup time reduced by 40%) Automated production coordination (manual intervention reduced by 60%)

- 2025 Invention Patent: Polyurethane casting machine for high-viscosity elastomers, solving pigment dispersion challenges

Industry Trends: Precision Manufacturing Driving Equipment Upgrades

- Semiconductors & New Energy: By 2025, China’s polyurethane polishing materials market will reach CNY 3.86 billion, with semiconductors contributing over 60% of growth, CAGR 12.3%

- Advanced CMP (Chemical Mechanical Polishing): As chip integration surpasses 3 nm nodes, wafer flatness requirements approach 0.1 nm, making CMP critical for yield improvement

- EV Lightweighting: Global automotive polyurethane polishing materials market will exceed USD 10 billion by 2025 Feilong’s nitrile rubber-based polishing pads, produced via isostatic pressing, reduce defect rates to 0.02%—62% lower than industry standard, meeting automotive-grade semiconductor requirements

Customization & Partnership: Building a Precision Manufacturing Ecosystem

Feilong offers full-chain customization, from material properties to process integration:

- Product level: Special sizes (standard 1397×584 mm, thickness 0.51–10 mm), grooving, perforation, adhesive backing

- Equipment level: Parameter adjustment based on material characteristics and process conditions, including dedicated production line development

From microstructure optimization of polishing pads to full-scale production line implementation, Feilong transforms “customization” into a systemic capability, becoming a long-term partner for process upgrades and driving the precision manufacturing industry toward greater flexibility and efficiency.