Traditional mold-based processes for producing polyurethane elastomer products face significant limitations, including high mold costs, lengthy production cycles, and environmental concerns from toxic raw materials. These challenges severely restrict flexibility in customized production and hinder sustainable industry development.

Feilong Polyurethane Equipment has pioneered mold-free rotational technology (also known as rotational casting), a groundbreaking solution that eliminates the dependence on molds by introducing a “dynamic coordinated forming” principle. The core mechanism lies in the precise synchronization between roller core rotation and the axial movement of the pouring head:

- The roller rotates steadily at 30 r/min,

- While the pouring head moves axially at 100 mm/min,

- Enabling the material system—comprising MDI prepolymer and chain extenders such as E-300 and BDO—to rapidly gel and solidify on the roller surface without high-temperature post-curing, achieving direct product formation.

Three-Dimensional Process Innovations

- Mold-Free Forming Breakthrough Using touchscreen and PLC-integrated control, the system synchronizes pouring speed, roller rotation, and material flow in real-time. This allows flexible production of rollers with varying thicknesses and hardness levels, eliminating downtime from mold changes.

- Low-Temperature Curing Optimized material formulation significantly shortens gel time. Combined with centrifugal force generated by roller rotation, the product cures uniformly at room temperature—reducing energy consumption and preventing thermal degradation of material properties.

- Intelligent Process Control By applying the “constant-speed deformation principle” and “final pass full forming principle,” the system adjusts parameters in real-time to prevent surface defects such as cone-end cracks and wrinkles. The result: dimensional accuracy of ±0.1 mm and surface roughness Ra ≤ 1.6 μm.

Compared with traditional mold-based processes, Feilong’s mold-free rotational technology replaces static molds with a dynamic process, reducing production cycles by over 60%, improving material utilization up to 95%, and eliminating mold storage and maintenance costs. This makes it especially suitable for small-batch, multi-specification customized roller production. Beyond equipment innovation, this process establishes an integrated theory of material-motion-control, setting a new paradigm for green and intelligent polyurethane manufacturing.

Industry Benchmarking: Technical Superiority and Economic Value

Feilong’s mold-free rotational technology demonstrates clear advantages through horizontal process comparisons and vertical market substitution.

Horizontal Process Comparison: Complete Breakthrough Over Conventional Methods

| Comparison Item | Traditional TDI Mold Casting | Feilong Mold-Free Rotational Casting |

|---|---|---|

| Mold Requirement | High-cost mold for each size | No molds needed – zero mold investment & storage |

| Curing Method | High-temperature post-curing (energy-intensive) | Rapid room-temperature curing – no post-curing |

| Production Cycle | Long (includes post-curing time) | Short (saves ~3 hours per 1000 mm roller) |

| Raw Material Toxicity | Toxic TDI & MOCA (suspected carcinogen) | Low-toxicity MDI for safer operations |

| Defect Repair | Difficult after demolding | Real-time monitoring – high yield rate |

| Cost Structure | High mold, energy, and material costs | Lower energy cost, no mold cost, high material utilization |

By eliminating molds and implementing room-temperature curing, Feilong’s process reduces production time by about 3 hours per 1000 mm roller, significantly lowers energy consumption, and removes the toxic hazards associated with TDI and MOCA.

Core Breakthroughs:

- Real-time monitoring ensures a higher product yield (compared to 85% in traditional processes).

- No mold costs + lower energy = 30%+ cost savings.

- Delivers the triple advantage of cost reduction, quality improvement, and efficiency enhancement.

Technical Innovations: From Material Science to Process Engineering

Two key innovations drive this breakthrough:

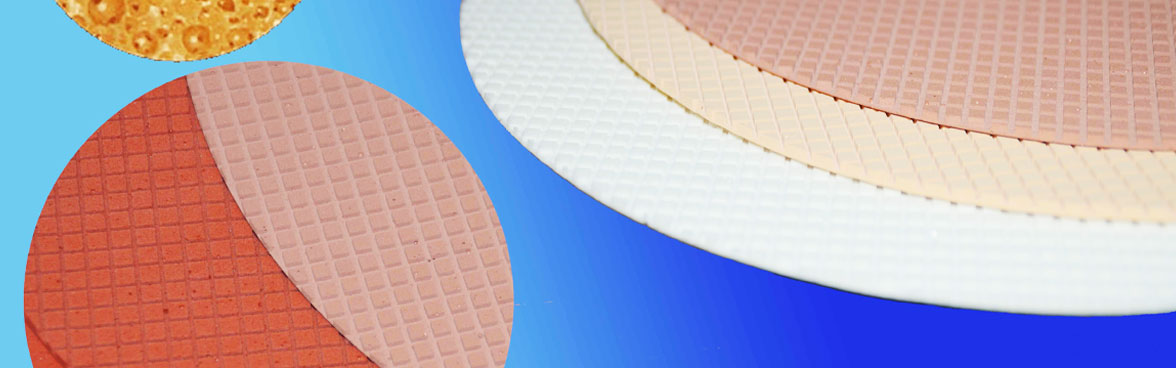

- Glass Fiber-Reinforced Intermediate Layer with Epoxy Resin – Prevents coating delamination common in traditional polyurethane coating methods, ensuring structural stability.

- Rotational Shear Mixing + Flat Elongated Nozzle Design – Solves uneven mixing and thickness variation issues, achieving uniform material blending and precise thin-layer coating.

These advancements create a robust competitive edge and high technical barriers for replication, especially in high-end markets.

Application Scope

Polyurethane products manufactured using Feilong’s mold-free rotational technology are widely applied across printing, papermaking, steel, grain processing, textiles, rail transit, and military industries. This technology’s flexibility supports both universal industrial needs and customized solutions for specialized sectors, covering the entire value chain from basic production to advanced equipment manufacturing.