MC Nylon (monomer casting nylon) is a critical material in the engineering plastics sector, renowned for its high strength and wear resistance. It is widely used in mechanical manufacturing, automotive, and mining equipment. However, traditional MC nylon production processes face three major challenges that significantly restrict industry growth:

1. Outdated Equipment and Inefficient Processes

Traditional setups rely heavily on manual operation, with molds manually fixed using screws, resulting in low mold clamping efficiency. Temperature control uses open heating systems, causing mold temperature variations of up to ±20°C, which leads to uneven polymerization.

For example, in static casting for 50 mm MC nylon rods, a single mold can only produce one 0.3-meter rod per day, requiring two vacuum steps (dehydration and material addition), resulting in poor production continuity and high energy consumption.

2. Poor Product Quality Stability

Manual control introduces significant fluctuations in process parameters:

- Reaction temperature deviation: ±15°C

- Low pressure control accuracy

- Raw material ratio error: over ±5%

These variations directly affect polymerization rate and molecular weight distribution, limiting molecular weight to only 20,000–30,000, with mechanical property fluctuations exceeding 20%.

Industry data shows:

- Yield rate: only 60%

- Defects (bubbles, shrinkage cavities): up to 35%

3. Production Efficiency Bottlenecks

The batch process has a long cycle of 8–12 hours per batch, with equipment utilization below 60%. For 50 mm rods, daily output per operator is only 0.5 tons, compared to 8 tons per operator with automation—a 16x efficiency gap. Labor costs account for over 30%, and high-temperature work poses safety risks.

Feilong’s Technical Solutions for MC Nylon Production

1. High-Precision Metering & Mixing System

- Custom metering pumps: Made from special alloys, maintaining ±0.5% accuracy at 200°C, combined with mass flow meters for closed-loop control, reducing ratio error to ±0.3%.

- Self-cleaning casting head: Innovative flow channel design eliminates dead zones, with material residue under 0.1%, allowing product changeovers without disassembly or contamination.

- Vacuum degassing module: Multi-stage buffering achieves 99.75 kPa vacuum, improving dehydration efficiency by 40%, with moisture content reduced to ≤0.05%, preventing bubbles.

2. Intelligent Control System

- PLC-controlled platform: 10.1-inch touchscreen, real-time monitoring of 12 key parameters (temperature accuracy ±5°C), 100+ formula storage, reducing product switch time from 4 hours to 15 minutes.

- PID temperature control: Infrared + electric heating ensures mold temperature difference within 3°C, ensuring uniform polymerization and raising molecular weight to 80,000+.

- Remote diagnostics: Industrial IoT connectivity provides real-time status monitoring, 90% fault prediction accuracy, reducing maintenance response to 2 hours.

3. Advanced Vacuum & Heating Integration

- Rapid direct heating system: Stainless steel tanks with high-frequency heating reduce melting time from 40 min to 15 min, cutting energy consumption by 25%.

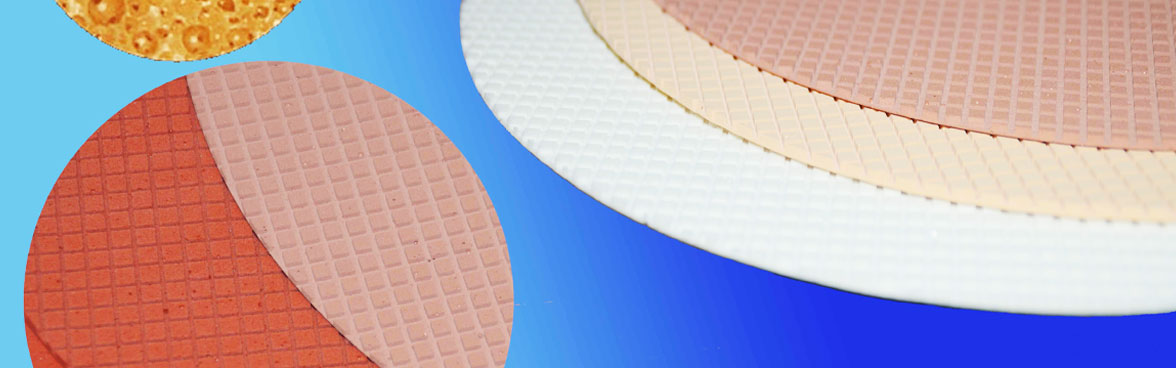

- Centrifugal casting technology: Horizontal centrifugal casting with axial rotation promotes uniform material distribution, eliminating shrinkage defects and raising yield to 95%.

Quantitative Performance Improvements

| Metric | Traditional Process | Feilong Automation | Improvement |

|---|---|---|---|

| Molecular Weight | 20,000–30,000 | 80,000+ | 2–3x |

| Yield Rate | 60% | 95%+ | +35 pts |

| Daily Mold Output | 1 piece / 0.3 m | 80 pieces / 1 m | 160x |

| Energy Consumption | — | ↓30% | — |

| Labor Requirement | 5 operators / line | 1 operator / 3 lines | ↓80% |

Real-World Applications

Mining Industry

A major mining company adopted Feilong’s automated system to produce MC nylon bushings (φ200×φ160×160), replacing traditional copper alloy parts. After handling 5.265 million tons of ore in 40–42°C outdoor conditions, the bushings showed no significant wear.

- Service life: 4–5 times longer than copper alloy

- Annual maintenance savings: ¥120,000 per unit

Automotive Industry

An automotive crane manufacturer replaced steel pulleys with MC nylon pulleys, reducing part weight by 70% (400 kg nylon vs. 2.7 tons steel), improving lifting performance by 15%.

- Wire rope lifespan: Extended 10x

- Annual spare part savings: ¥150,000 per unit

Conclusion & Value Proposition

Feilong’s automated MC nylon production technology delivers three breakthroughs:

- Quality improvement: Molecular weight increased to 80,000+, property fluctuation reduced from 20% to 3%.

- Efficiency revolution: Continuous production boosts mold output 160x, labor cost down 80%.

- Cost optimization: Energy consumption down 30%, payback period shortened to 2.3 years.

This innovation supports “Replace Steel with Nylon” strategies, enabling lightweight solutions for high-end equipment. Future applications extend to aerospace, marine engineering, and beyond, promising enormous market potential.