Industry Challenges and the Inevitable Material Revolution

Frequent breakage of fiberglass mannequin stands during logistics and the deformation and aging of plastic mannequins in retail stores due to temperature changes have long plagued the industry. Polyurethane materials, with their lightweight strength, precise molding, and eco-friendly durability, are gradually replacing traditional materials. As a pioneer in equipment innovation, Feilong Polyurethane Equipment achieved a 30% energy-saving breakthrough as early as 2003, led the development of two corporate standards in 2004 to fill domestic gaps, and continues to drive industry upgrades through sustained R&D investment.

The Drawbacks of Traditional Materials:

- Fiberglass: Heavy and fragile, causing high transportation losses.

- Plastic: Prone to deformation and aging under temperature changes, leading to higher operational costs and poor display quality.

Core Equipment Matrix: The Key to Solving Complex Molding Challenges

Low-Pressure Foaming Machine: Precision Revolution for Complex Shapes

The Feilong Polyurethane Low-Pressure Foaming Machine delivers breakthrough performance through three key upgrades:

- Mixing ratio accuracy: ±1% (vs. traditional ±3%)

- Metering pump accuracy: ≤0.5% (vs. traditional ≥1%)

- Temperature control: ±1°C

With 3D space rotation technology, forming accuracy for fine details such as fingers and toes increased the pass rate from 75% to 98%. The PLC control system supports 100 preset formulas, reducing model changeover time to one-third of traditional equipment.

Core Advantage: By combining precise dosing, dynamic molding, and intelligent control, Feilong redefines mannequin manufacturing standards.

Elastomer Casting Machine: Material Adaptation and Bubble-Free Molding

For mannequin stands requiring Shore hardness D65-80, Feilong equipment ensures ±0.5% dosing precision and uses bubble-free mixing head technology to eliminate air pockets.

Proven results:

- One-shot forming rate: 85% → 98%

- Scrap rate reduced by 60%

- Production cycle shortened by one-third

Auxiliary Systems: Boosting Efficiency and Safety

- Automatic mold-opening system: 15-minute mold change (vs. 1–2 hours traditionally)

- 3D rotation system: Density deviation controlled within ±2%

- Circular assembly line: Daily mold output 2.3x higher than conventional processes

- Safety: Mechanical lock + pneumatic system reduce injury risks

Full-Process Innovation: From Raw Material to Finished Product

Materials & Formulations: Balancing Eco-Friendliness and Performance

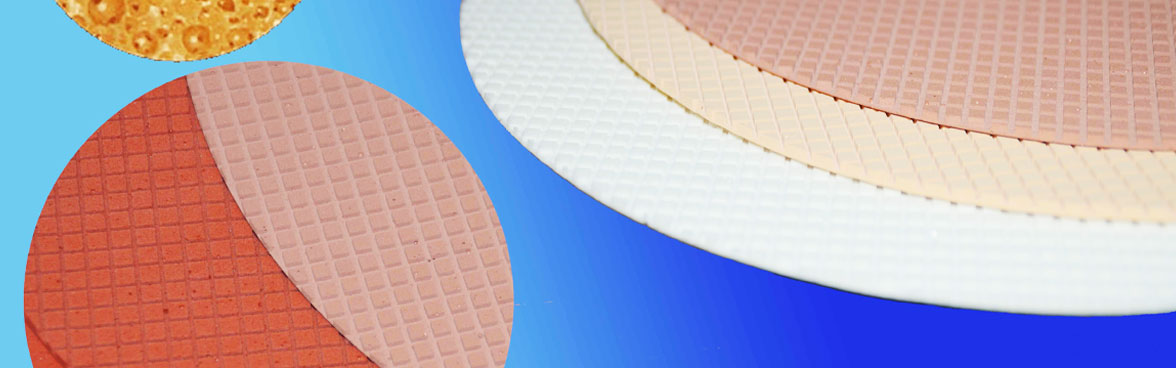

Polyurethane materials are solvent-free and recyclable, compliant with EU RoHS standards. Formula control with ±0.5% accuracy ensures tailored performance:

- PO-645 (Shore 45A): Elongation 700%

- CU-290 (Shore 90A): Tensile strength 6,500 psi

Pre-treatment steps include mold cleaning, raw material drying (moisture ≤0.05%), and dynamic mixing.

Mold Forming & Smart Inspection: Achieving Millimeter-Level Precision

- 3D-printed master mold: Surface roughness Ra0.8

- Steel mold with 55–60°C temperature control

- Thickness deviation: ±0.5 mm

- Smart QC: Laser thickness gauge (0.01 mm), hardness tester, AI vision system Result: Over 99% product pass rate

Four Pillars of Feilong’s Technical Advantage

1. High-Precision Metering & Mixing:

Achieve “gram-level control” with ±0.5% accuracy and 30% better color dispersion, ensuring zero color difference for premium displays.

2. Automation & Smart Control:

- PLC system reduces labor from 4 operators to 1

- Changeover time cut from 2 hours to 20 minutes

- Integrated line enables unmanned production with >99% consistency

3. Green Manufacturing:

- Water-circulation heating saves 65% energy

- Solvent recovery minimizes emissions

- Foam recycling technology reduces waste

- Full compliance with EU REACH standards

Conclusion: Partnering for Industry Upgrades

Feilong Polyurethane Equipment has evolved from an equipment supplier into a strategic partner for production upgrades. With customized solutions for both flexible and high-speed continuous production, Feilong empowers mannequin display stand manufacturers to achieve higher precision, greater efficiency, and sustainable growth.