I. Industry Challenges: Environmental Compliance and Precision Control

The medical materials industry faces strict regulatory requirements and increasing technical challenges. Traditional polymer materials often struggle with residual solvents, VOC emissions, and other environmental compliance issues. At the same time, manual or semi-automated production leads to variations in product quality—especially in high-end applications such as implantable medical devices and advanced wound dressings where precision and consistency are critical.

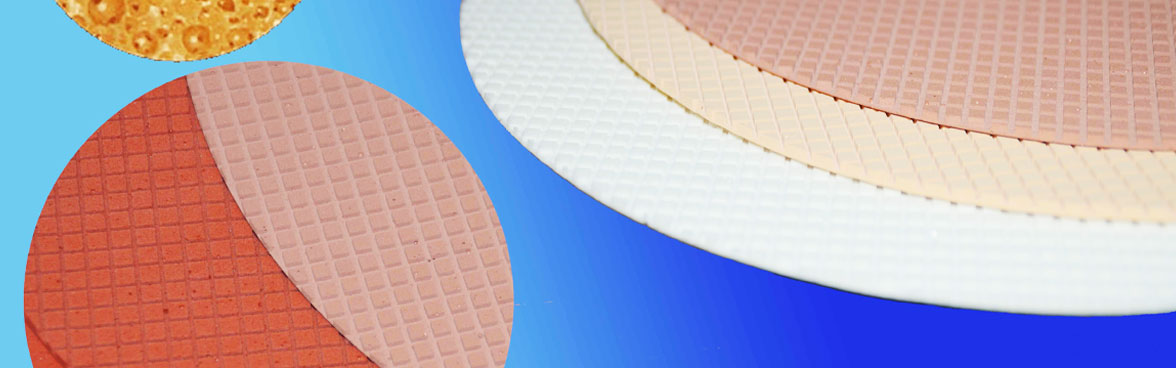

Polyurethane foam has emerged as an ideal alternative to conventional rubber and silicone, thanks to its biocompatibility, controllable pore structure, and eco-friendly manufacturing process. To fully unlock this potential, Feilong’s new series of eco-friendly polyurethane foam equipment offers a complete solution for high-precision, large-scale medical material production, driving the industry toward smart manufacturing and sustainable development.

II. Feilong’s Eco-Friendly Foam Equipment and Core Features

Feilong’s equipment is designed with medical-grade adaptability in mind, covering the entire production chain from formulation development to precision encapsulation. The key equipment includes:

1. Precision Micro Foaming Test Machine

- Minimum flow control accuracy: 0.3 g/s

- Supports multi-component dynamic mixing for process simulation

- Ideal for R&D of antimicrobial dressings and orthopedic liners

- Reduces formulation iteration time by 40%

2. Solvent-Free Curing Oven

- Temperature control accuracy: ±1°C

- Advanced hot-air circulation ensures zero VOC emissions

- Energy consumption reduced by 30%

- Fully compliant with ISO 10993 biocompatibility standards

3. High-Performance Resin Potting Machine

- Integrated vacuum degassing

- Flow control accuracy: ±0.5%; repeat positioning accuracy: ≤0.02 mm

- Micro potting as low as 0.01 ml

- Proven for heart pacemaker sensors and minimally invasive surgical instruments

- Finished product yield rate: ≥99.2%

III. Three Core Advantages Driving Industry Transformation

1. Smart Manufacturing & Full-Process Traceability

- Integrated ERP production management system

- Real-time monitoring of material ratios, curing temperature, and pressure curves

- Human error controlled within ±1%, batch performance deviation ≤2%

- Fully compliant with GMP standards for medical consumables

2. Green Technology & International Certification

- Proprietary solvent-free foaming process eliminates harmful residues such as formaldehyde and benzene

- Certified under ISO 9001 and ISO 13485 quality systems

- Products approved by CE and SGS

- Listed in multiple government green equipment procurement catalogs

3. Precision Engineering & Material Performance Control

- Adjustable foaming ratio: 10–50 times

- Open-cell foam: 40% higher water absorption for wound dressings

- Closed-cell foam: Impact resistance up to 2.8 MPa for protective pads

- Accurate pore distribution: 50–300 μm, ideal for advanced wound care

IV. Key Application Scenarios

1. Biocompatible Polyurethane Elastomers

- Hardness range: Shore A 30–90

- Applications include artificial cartilage (friction coefficient 0.08–0.12) and nerve conduits (controlled degradation cycle of 6–12 months)

- Successfully passed L929 cytotoxicity tests (cell viability >90%)

2. Advanced Medical Consumables

- Functional Wound Dressings: Low-density foam (0.15–0.3 g/cm³) with 3D interconnected pores, absorbs 8–10 times its weight in exudate

- Medical Sensor Encapsulation: Micro potting with bubble defect rate <0.05%, improving signal stability by 25%

V. Conclusion: A Strategic Driver for Medical Manufacturing

Feilong’s eco-friendly polyurethane foam equipment combines smart automation, green processing, and precision engineering to deliver a full-process solution from R&D to mass production. By addressing key pain points such as environmental compliance and product consistency, Feilong enables medical material manufacturers to meet international standards while reducing costs, accelerating the transition toward sustainable and high-quality healthcare solutions.