In polyurethane foam production, a minor deviation in mixing ratio, a brief temperature fluctuation, or a slight mold misalignment can turn an entire batch into scrap. For manufacturers in footwear, automotive interiors, insulation panels, or industrial cushioning components, low yield rates and frequent equipment failures are not theoretical concerns—they are daily profit killers.

In many cases, the root cause is not the formulation itself, but a more fundamental question:

Does your equipment genuinely understand your process?

Precision Is No Longer Optional in Modern PU Foaming

Thanks to its lightweight structure, high resilience, and excellent thermal insulation and cushioning performance, polyurethane (PU) foam has become a material of choice across multiple high-end manufacturing sectors. However, these advantages come with extremely stringent process-control requirements:

- A/B component mixing ratio must remain within ±1% Any deviation directly affects crosslink density and final mechanical properties.

- Reaction temperature fluctuations exceeding ±2°C Can lead to uneven cell structures, shrinkage, or deformation.

- Mismatch between pouring path, speed, and mold geometry Often results in voids, short shots, or material overflow.

- Frequent equipment downtime Disrupts production rhythm and increases labor intervention and operational costs.

Many manufacturers initially invest in so-called “standard machines” that appear functionally sufficient but lack deep adaptability to specific applications. The outcome is a familiar scenario: the formulation is optimized, yet the equipment becomes the bottleneck.

Feilong’s Core Philosophy: Equipment as an Extension of the Process

From its inception, Feilong Polyurethane Equipment has adhered to one guiding principle:

Equipment should not be an isolated machine—it should be a direct extension of your process.

As a National High-Tech Enterprise, Feilong does not simply stack hardware specifications. Instead, it translates decades of hands-on experience across footwear soling systems, automotive seating, cold-storage panels, and wind turbine blade infusion into intelligent control logic and modular system architecture.

Representative Feilong Solutions

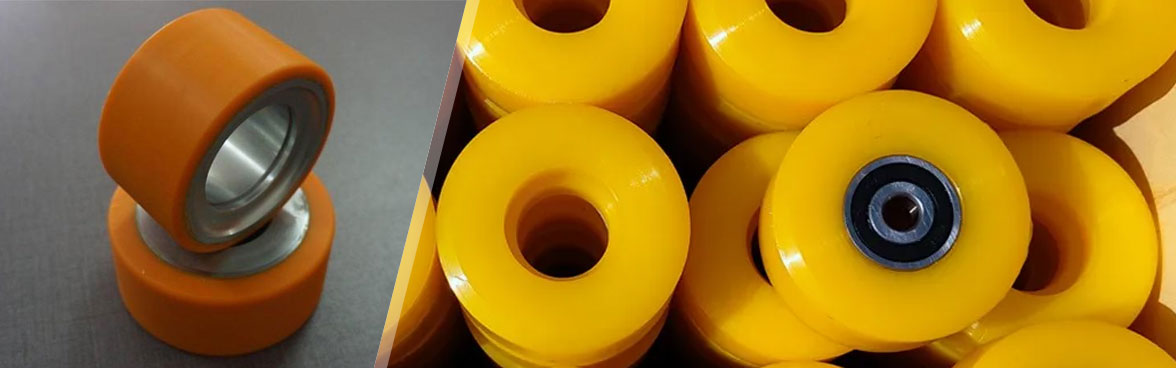

High-Precision Polyurethane Elastomer Casting Machines

Equipped with closed-loop metering systems and dynamic pressure compensation, Feilong machines maintain A/B ratio stability within ±0.5% even during long, continuous operation. This makes them ideal for high-value elastomer products such as mining screens and industrial rollers, significantly improving consistency in mechanical performance.

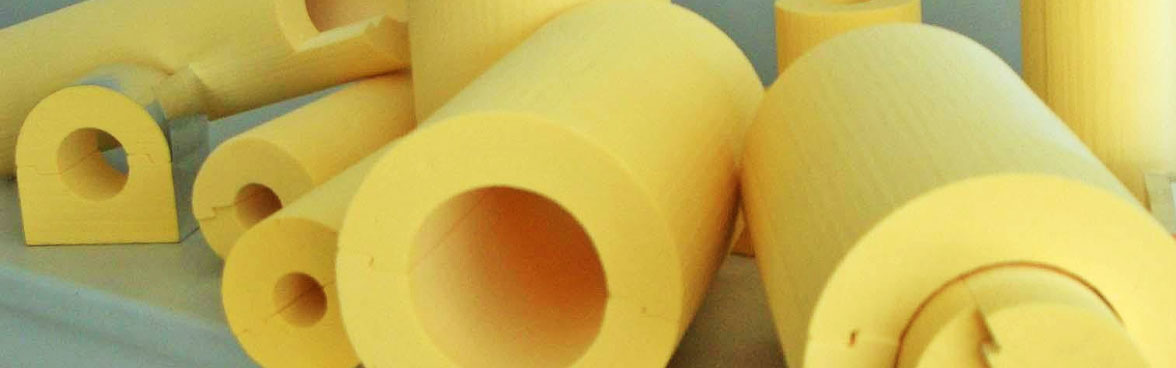

Intelligent Temperature-Controlled PU Foaming Systems

Featuring multi-zone independent heating with real-time feedback regulation, temperatures across material tanks, pipelines, and mixing heads are individually set and automatically calibrated. Combined with CE-certified safety interlock systems, these solutions ensure complete reactions while preventing yellowing or material degradation caused by overheating.

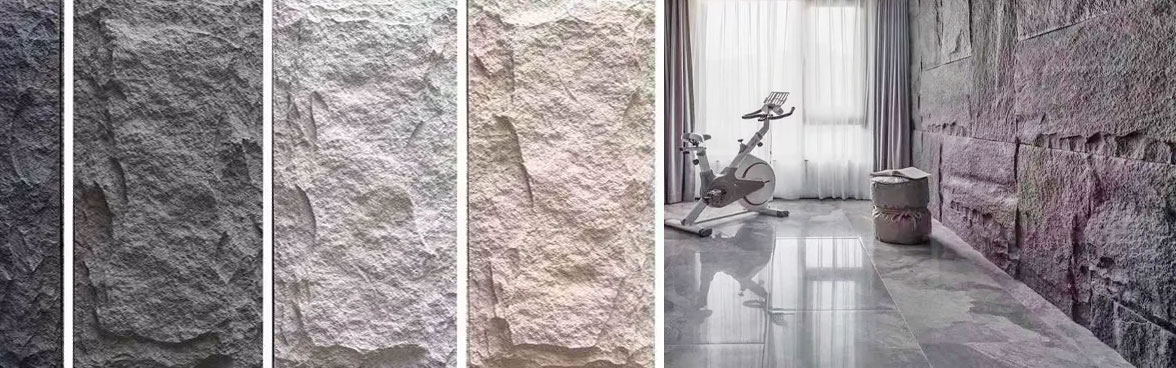

Flexible Mold-Carrying Production Lines

Designed to support rapid mold changes and non-standard mold configurations, these systems use PLC + HMI interfaces to pre-store optimized pouring curves (flow rate, time, and path) for different products. Operators simply select a process ID, and the equipment executes the predefined casting strategy—dramatically reducing reliance on operator experience.

Custom Engineering & Development Capability

Moving from “usable” to “precisely matched,” Feilong openly commits to:

Designing and prototyping polyurethane equipment to meet special or unconventional requirements.

Whether for large-scale vacuum infusion systems for wind turbine blades or micro-precision dispensing units for electronic encapsulation, Feilong’s engineering team provides full-cycle support—from process simulation and layout integration to prototype validation—based on real production conditions.

Conclusion: Choosing Equipment Is Choosing Production Certainty

In the polyurethane foam industry, competition has evolved from having capacity to consistently producing qualified products. With over 20 years of specialization, 30+ patented technologies, and a quality system certified to ISO 9001 and CE standards, Feilong Polyurethane Equipment delivers what manufacturers value most today:

Predictable, repeatable, and optimizable production certainty.