Polyurethane foaming technology, as the core process in modern insulation manufacturing, plays an irreplaceable role in car refrigerator production. Feilong Polyurethane Equipment is taking the lead with intelligent and eco-friendly manufacturing solutions—equipping car refrigerators with a “thermal insulation heart.”

Polyurethane Foaming: The “Thermal Code” Behind Car Refrigerators

The principle of polyurethane foaming is a precise “chemical reaction art.” When isocyanate (black material) and polyether polyol (white material) react in a mold with catalysts and foaming agents, they generate heat, causing the foaming agent to vaporize and form countless fine bubbles. The result is a rigid foam layer with a closed-cell rate exceeding 92% (source: Basic Knowledge of Refrigerator Foaming). This structure maintains a thermal conductivity of ≤0.021 W/m·K and limits temperature fluctuations to less than 1 °C over 24 hours at -15 °C.

A key environmental breakthrough lies in the use of cyclopentane as the foaming agent. Unlike traditional CFCs, cyclopentane has an ozone depletion potential (ODP) of zero and a global warming potential (GWP) that’s only 1/10,000 of CFC-11, while offering superior gas-phase insulation. However, its high flammability demands extreme equipment precision. Feilong’s polyurethane systems use a static pre-mixing mechanism and explosion-proof monitoring to maintain a precise ratio of 13.5:100 ± 2% between cyclopentane and polyol, with pipeline pressure stabilized between 0.2–0.5 MPa, eliminating potential safety hazards at the source.

Feilong Polyurethane Equipment: The “China Solution” for Intelligent Manufacturing

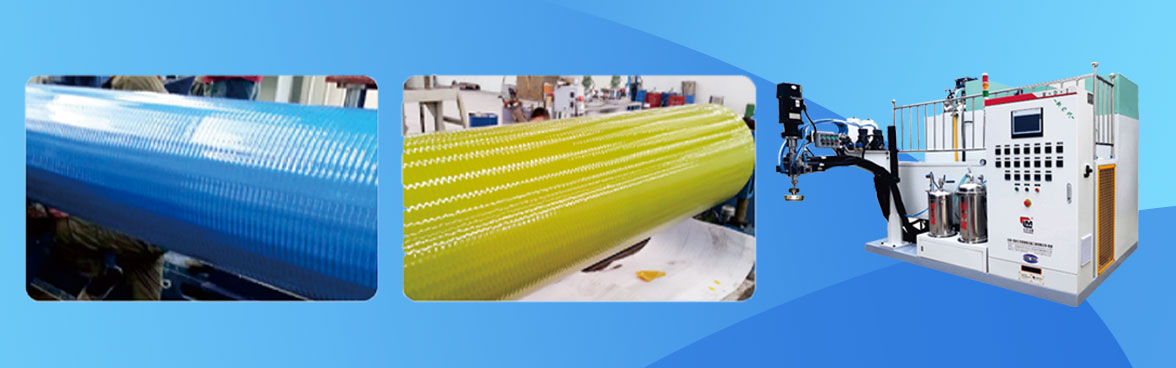

Inside Feilong’s workshops, the company’s high-pressure foaming machines perform with millimeter-level precision: an output range of 0.1–500 kg/min, mixing ratio accuracy within ±1%, and injection pressure stabilized at 15–16.5 MPa. Foam density deviation per cubic meter stays below 0.5 kg. These results come from three intelligent innovations:

- ERP-Integrated Process Control — Connecting raw material, production, and quality inspection data into a closed loop. PLC systems continuously collect over 20 parameters (material temperature 25 ± 5 °C, mold temperature 40 ± 5 °C, etc.), while AI algorithms auto-adjust pouring flow (680 ± 10 g/s). The result: product qualification rates rise from 78% to over 95%.

- Unlimited Functional Expansion — Feilong’s 12-component elastomer equipment can inject materials of different colors and densities simultaneously, forming composite insulation layers with antibacterial coatings in a single process. This enables features like “cooling + insulation + sterilization” for brands such as Aikai Holdings, whereas traditional systems support only 2–3 components.

- Comprehensive Technical Support — As a branch of the National Reaction Injection Molding Engineering Technology Research Center, Feilong offers full-chain services from mold design to process tuning. For instance, when a new-energy vehicle maker faced foam shrinkage issues due to size constraints, Feilong’s engineers used 3D flow-field simulation to optimize injection point design—boosting foam filling efficiency to 98% and eliminating local shrinkage.

From Follower to Leader: Feilong’s Three Core Advantages

In the car refrigerator sector, Feilong Polyurethane Equipment stands out with precision, efficiency, and environmental superiority:

- Precision that Outperforms Conventional Machines — Traditional low-pressure systems cause uneven mixing and ±0.003 W/m·K variations in thermal conductivity. Feilong’s high-pressure dual-mixing head technology achieves bubble diameter deviation ≤0.1 mm and closed-cell consistency above 92%, ensuring stable insulation performance between -20 °C and 55 °C with less than 5% thermal decay.

- Efficiency Up by 30% — With a 70-second rapid demolding process, each unit can produce up to 300 refrigerators per day, equivalent to one insulation layer every 220 seconds. One leading automaker reported an 18% cost reduction per unit and annual material savings exceeding 5 million RMB after adopting Feilong’s system.

- Environmental Leadership — Beyond cyclopentane, Feilong has developed CO₂ foaming alternatives, reducing the GWP value to just 1, further aligning with global sustainability standards.

Conclusion

At the intersection of the dual-carbon goals and the new-energy revolution, Feilong Polyurethane Equipment is more than a machine—it symbolizes China’s shift from scale expansion to technological breakthrough. As more car refrigerators are powered by the “Feilong Core,” the future may redefine mobility itself: your vehicle could become a mobile smart preservation capsule. And at the heart of this transformation lies the invisible brilliance of polyurethane foam—an embodiment of Chinese innovation.