The new energy industry is reshaping the global energy landscape at an astonishing pace. In this green revolution, one critical material—polyurethane—has quietly become the “behind-the-scenes hero” in wind and solar power systems. At the upstream of this production chain, Feilong Polyurethane Equipment, with over two decades of technological expertise, is emerging as a key enabler of efficiency and innovation in renewable energy manufacturing.

As a National High-Tech Enterprise, Feilong has leveraged intelligent and customized equipment solutions to secure a strong foothold in the production of wind power cable protection pipes and photovoltaic cutting rollers—two critical components underpinning the high-quality development of the clean energy industry.

Wind Power Sector: Building “Protective Armor” for Marine Environments

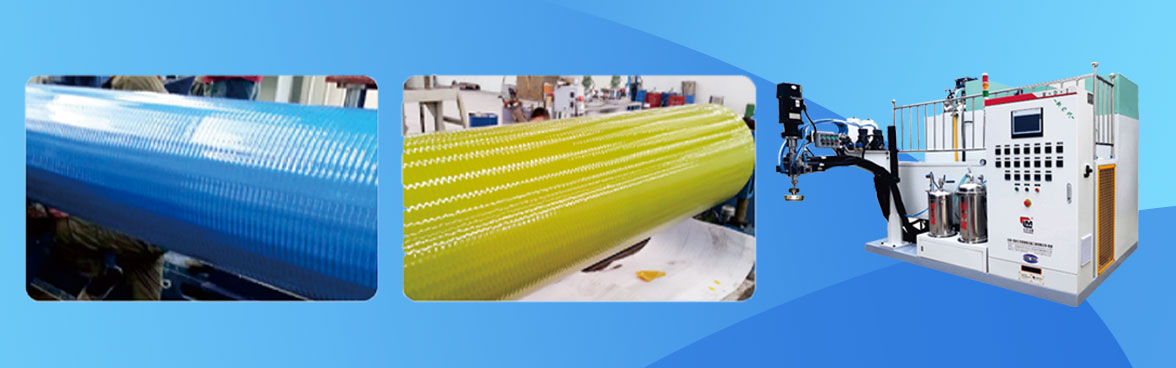

Offshore wind power has become the new engine of the global energy transition. However, the harsh marine environment—with high salinity and corrosion—poses severe challenges to material durability. Polyurethane cable protection pipes, known for their exceptional resistance to corrosion, wear, and hydrolysis, have become the “lifeline” of offshore wind farms—and their performance relies heavily on the precision and stability of the forming equipment.

Feilong’s elastic polyurethane casting machines deliver outstanding advantages in this field. As an authorized sub-center of the National Reaction Injection Molding Engineering Technology Research Center, Feilong has developed a casting system with a high-precision metering control—keeping raw material ratio errors within ±0.5%. This ensures a uniform molecular structure, boosting salt-spray resistance by 30% and extending service life beyond 25 years.

Moreover, its intelligent PLC-controlled automation module enables full-process automation, improving production efficiency by 40% while reducing the defect rate from the industry average of 5% to just 1.2%.

Photovoltaic Industry: The “Invisible Guardian” of Cutting Precision

As the global photovoltaic industry accelerates its shift toward N-type cells, precision in wafer cutting becomes crucial for improving silicon utilization. Polyurethane photovoltaic cutting rollers, the core components in wafer cutting, must exhibit exceptional wear resistance (over 100,000 cutting cycles), scratch resistance (surface hardness ≥ Shore A 95), and load stability (deformation rate < 0.5%). These performance benchmarks depend on the quality of advanced polyurethane molding equipment.

Feilong’s specialized casting systems for photovoltaic rollers tackle the key production challenges with a multi-component elastic casting solution. The system precisely regulates the ratio of isocyanate and polyol, while its dynamic degassing technology reduces air bubble content to below 0.1%. As a result, roller surface roughness achieves Ra 0.8 μm, ensuring wafer thickness deviations stay within ±2 μm, greatly enhancing cutting precision and consistency.

Technological Breakthrough: From Follower to Industry Standard Setter

Feilong Polyurethane Equipment’s rapid rise in the renewable energy sector stems from its deep technological foundation. The company holds 55 national patents, has led the drafting of 2 polyurethane equipment standards, and participated in multiple industry regulations.

The Academician Li Junxian Research Workstation, established in 2015, marked another leap forward in innovation. One of its key developments—a solvent-free polyurethane coating process—solves the issue of excessive VOC emissions in traditional methods, reducing environmental costs by 40% in photovoltaic roller production.

Another pillar of Feilong’s leadership is smart manufacturing. The company’s end-to-end ERP management system enables full data traceability from raw material mixing to final inspection. Paired with a remote monitoring platform, it reduces equipment failure rates by 60% and cuts average maintenance response time to just 2 hours.

The “Hidden Champion” Logic Behind the Green Revolution

As the global polyurethane market continues to expand, Feilong’s story reflects a profound truth: in the “arms race” of renewable energy, the equipment behind core materials has become a decisive competitive factor.

Through its integrated capabilities in material R&D, equipment manufacturing, and process optimization, Feilong not only breaks the dependence on imported high-end polyurethane machines but also empowers renewable energy companies to reduce costs and boost efficiency. With millimeter-level precision and percentage-level efficiency gains, Feilong is helping to build the foundation of global energy transformation—quietly, but powerfully.