Technological Breakthroughs Amid Industry Trends

In 2025, the global polyurethane market is expected to maintain a compound annual growth rate (CAGR) of 8.5%, with high-end equipment and advanced material substitution serving as key growth drivers.

Against this backdrop, Feilong Polyurethane Equipment has emerged as a national leader in the field — serving as a Sub-center of the National Reaction Injection Molding Engineering Technology Research Center and a Council Member of the China Polyurethane Association.

With 54 patents, 12 software copyrights, and 8–12% of annual revenue invested in R&D, Feilong has become a benchmark enterprise in polyurethane casting equipment manufacturing in China.

Core Technology: From Material Performance to Equipment Innovation

Revolutionary Material Performance

Products made with Feilong casting nylon equipment reach molecular weights up to 80,000, over twice that of conventional injection-molded nylon (20,000–30,000).

This results in a qualitative leap in mechanical performance:

- Shore hardness adjustable from D60–80

- Wear resistance 4–5 times higher than that of metal components

- 100% recyclable waste material, reducing per-ton production costs by 18%

These advantages enable “plastic replacing steel” in heavy-duty industries such as mining and steelmaking.

Six Key Equipment Innovations

- High-Precision Metering System Custom-designed metering pumps maintain ≤0.5% dosing accuracy at 300°C, solving the issue of mix-ratio deviation caused by thermal fluctuations (industry average error: 2–3%).

- Maintenance-Free Casting Head The bubble-free self-cleaning design eliminates the need for purging or solvent cleaning. Each casting cycle is three times faster than traditional machines, saving over ¥200,000 per unit annually in solvent costs.

- High-Temperature & High-Pressure Resistance The use of imported special alloy heating wires and PID temperature control (±1°C) enables processing of high-viscosity polymers (up to 5000 mPa·s).

- Multi-Stage Vacuum Buffer System Equipped with a dedicated cooling module, it prevents crystal precipitation and pump blockage — raising product yield from 85% to over 98%.

- Smart Control System PLC + touchscreen interface monitors 12 key parameters (pressure, flow, liquid level, etc.) in real time and supports remote diagnostics and up to 100 process formula storage.

- Green Production Design Mirror-polished stainless-steel tanks minimize residue, while a rapid direct-heating system halves raw material melting time, reducing total energy consumption by 25%.

Application Scenarios: From Heavy Industry to Precision Manufacturing

Mining & Steel: The Wear-Resistance Revolution

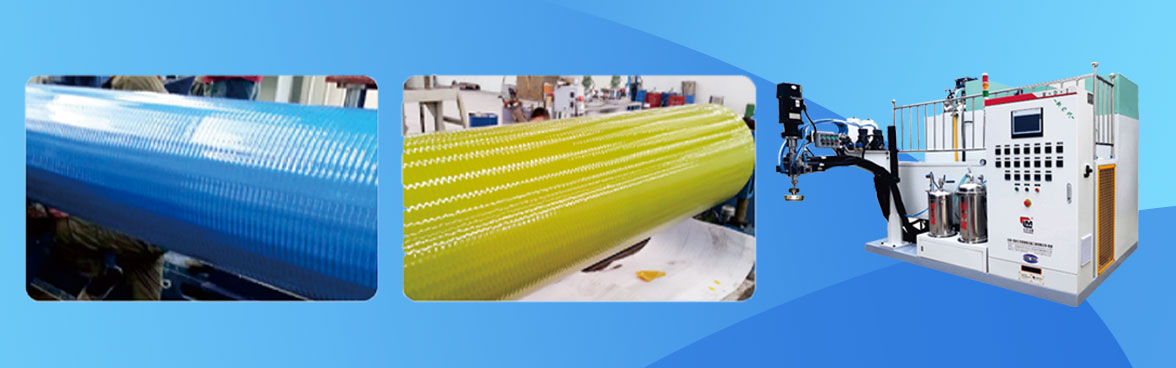

Feilong’s casting nylon equipment is used in roller sleeves, conveyor pulleys, and liners across more than 30 major steel enterprises, providing reliable performance in harsh, abrasive conditions.

Rail Transit & Marine: Lightweight and Corrosion-Resistant

In rail systems, components such as sliding bearings and couplings weigh 60% less than steel equivalents, maintaining stability from -40°C to +120°C.

In marine environments, nylon impellers replace bronze parts, extending seawater pump maintenance intervals from 3 months to 2 years.

Aerospace & Precision Manufacturing: The Ultimate Control Challenge

For aerospace applications, Feilong developed a vacuum potting device achieving ≤0.5% repeat dosing accuracy over 100 cycles, now used in missile signal encapsulation.

In precision machinery, Feilong’s OA roller components achieve roundness errors within 0.01 mm.

Conclusion

From heavy industry to precision engineering, Feilong Polyurethane Equipment is redefining industry standards through an integrated approach of equipment, materials, and process innovation.

As the polyurethane market advances, Feilong continues to drive the evolution of China’s high-end manufacturing with its technological leadership and engineering excellence.