In the wave of industrial automation, this key component—often described as the “nervous system” of automated equipment—is reshaping precision manufacturing with 98% transmission efficiency and a wide operating temperature range of -30°C to +80°C. At the upstream of this industrial chain, Feilong Polyurethane Equipment, backed by over two decades of technical expertise, provides the core manufacturing equipment for timing belt production—emerging as the invisible force driving industry advancement.

Polyurethane Timing Belts: The Benchmark for Automated Power Transmission

Six major performance advantages define the technological edge of polyurethane timing belts:

- High Wear Resistance – Exceptional durability under high-frequency, continuous operation; lifespan up to 8 times longer than traditional rubber belts.

- Low Noise Design – Smooth, quiet operation with noise levels below 65dB, ideal for medical and laboratory environments.

- Chemical Resistance – Stable performance under exposure to lubricants, detergents, and acids/alkalis; compliant with FDA food-contact standards.

- High Transmission Efficiency – Precision tooth geometry ensures perfect meshing with pulleys, achieving up to 98% transmission efficiency and minimal energy loss.

- Maintenance-Free Operation – No lubrication required, eco-friendly, and reduces maintenance costs by over 50%.

- Flexible Customization – Supports tailored tooth profiles, lengths, widths, and hole configurations for various applications.

Four Core Application Scenarios: From Precision Manufacturing to Smart Logistics

1. High-Speed Electronics Assembly Lines

In SMT placement machines, plug-in machines, and automatic dispensing systems, transmission systems demand extreme responsiveness and positioning precision. Polyurethane timing belts maintain stable motion even at high speeds, preventing slippage or tooth jumping that could cause misalignment.

A leading electronics manufacturer reported that after adopting polyurethane timing belts, its SMT line achieved ±0.02mm repeat positioning accuracy, ensuring precise placement of 01005 micro-components, with continuous operation exceeding 3,000 hours without tooth loss.

2. Medical and Laboratory Automation Equipment

Devices such as automatic biochemical analyzers, blood testing instruments, and drug dispensing systems require low noise and cleanliness. Polyurethane timing belts operate smoothly and quietly, producing minimal dust—ideal for sensitive environments.

In automated analyzers, belts move sample racks at 0.5 m/s, preventing vibration-induced testing errors. Their lubrication-free nature also meets GMP standards, minimizing contamination and infection risks.

3. Vision Inspection and Positioning Systems

In machine vision setups, camera modules or inspection platforms often require high-precision reciprocating motion. With ±0.01mm repeat positioning accuracy, polyurethane timing belts ensure stable image capture and improved detection efficiency.

In LCD panel inspection systems, a timing belt–driven platform achieves 2 m/s scanning speed while maintaining 0.02mm positioning accuracy, boosting inspection throughput by 40%.

4. Collaborative Robots and AGV Vehicles

For robotic joints, AGV drives, and mobile handling systems, polyurethane timing belts offer lightweight, high-efficiency power transmission.

In a logistics AGV retrofit project, replacing traditional gears with polyurethane belts reduced equipment weight by 15%, increased battery life by 20%, and extended service intervals.

In cobots, belt-driven joints passed 10⁶ bending fatigue cycles without degradation—ensuring long-term safety and reliability in human-robot collaboration.

Market Growth Logic: Dual Drivers of Automation and Material Innovation

Rising industrial automation adoption is a major growth driver. By 2025, the global polyurethane timing belt market is expected to reach 18.161 billion RMB, with the new energy vehicle (NEV) sector contributing the most incremental demand. Each power battery assembly line typically requires 15–20 high-precision timing belts.

Material innovation continues to unlock new applications. Carbon fiber–reinforced polyurethane boosts tensile strength by 30%, while graphene coatings further enhance wear resistance by 25%.

Industry forecasts suggest that by 2030, the high-end polyurethane belt segment will expand its market share from 18% to 30%, pushing total market value beyond 8.5 billion RMB.

Feilong Polyurethane Equipment: The “Hidden Champion” in Polyurethane Manufacturing

As a key branch of the National Engineering Research Center for Reaction Injection Molding Equipment, Feilong specializes in R&D and production of polyurethane machinery. Its four major product lines—elastomer casting machines, foaming systems, and specialized equipment—are supported by 54 patented technologies.

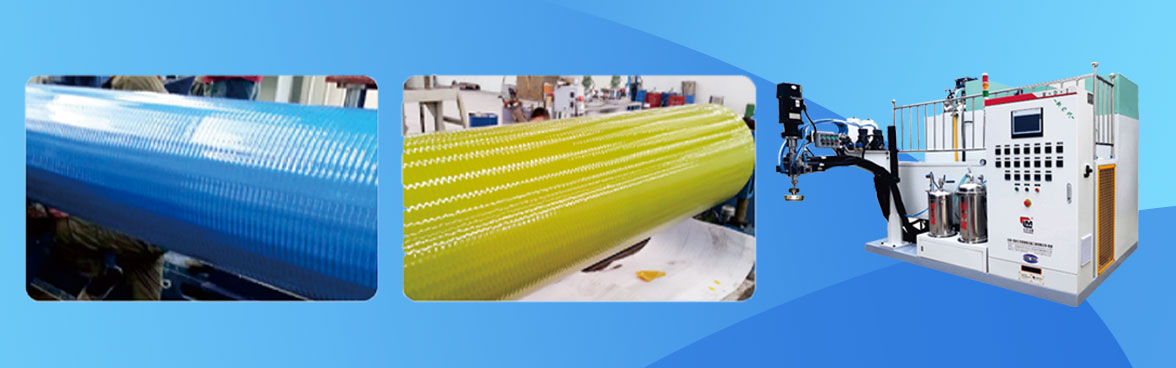

The company’s High-Precision Polyurethane Timing Belt Production Line broke foreign monopolies, achieving ±0.05mm tooth precision and improving productivity by 40% over imported systems.

End-to-end intelligent manufacturing is Feilong’s defining advantage. Through an ERP-integrated process, it enables full traceability from raw material batching to final inspection. One timing belt manufacturer reported that after upgrading to Feilong equipment, product yield increased from 82% to 95%, while energy consumption dropped by 18%.

An Indispensable Power Transmission Solution for the Smart Manufacturing Era

As smart manufacturing continues to evolve, demand for automation, miniaturization, and intelligent systems grows rapidly. With its exceptional performance and reliability, the polyurethane timing belt has become the preferred transmission solution for next-generation automated equipment.

Whether for standard production lines or customized systems, choosing high-quality polyurethane timing belts enables greater stability, longevity, and operational efficiency—powering the future of industrial automation.