The global polyurethane elastomer market is expanding at an annual compound growth rate of 7–8%. In this rapidly growing sector, Feilong Polyurethane Equipment is challenging the long-standing dominance of imported brands through over 50 patented technologies, redefining the standards of high-end polyurethane processing.

Four Major Technological Breakthroughs Redefining Mid-Temperature Wheel Equipment

Traditional polyurethane casting machines typically exhibit a 1.5% metering error. Feilong’s proprietary “Tank–Pump–Head–Control” four-dimensional coordination system reduces this deviation to less than 0.5%. Originating from aerospace fuel injection systems, this precision control technology marks a revolutionary leap for the polyurethane industry.

The company’s patented dynamic mixing head is another milestone. Unlike conventional static mixers, Feilong’s floating mechanical seal design maintains uniform blending at 3,000 rpm, ensuring consistent elastomer properties even under high-speed operation.

Feilong’s intelligent temperature control system uses a triple-jacket tank structure and PID self-tuning algorithm, achieving a ±2°C precision range. In extreme environments—from -50°C to +80°C, as seen in polar scientific equipment production—this system ensures material stability. The technology has been officially included in the Polyurethane Elastomer Casting Equipment Industry Standard (Group Standard).

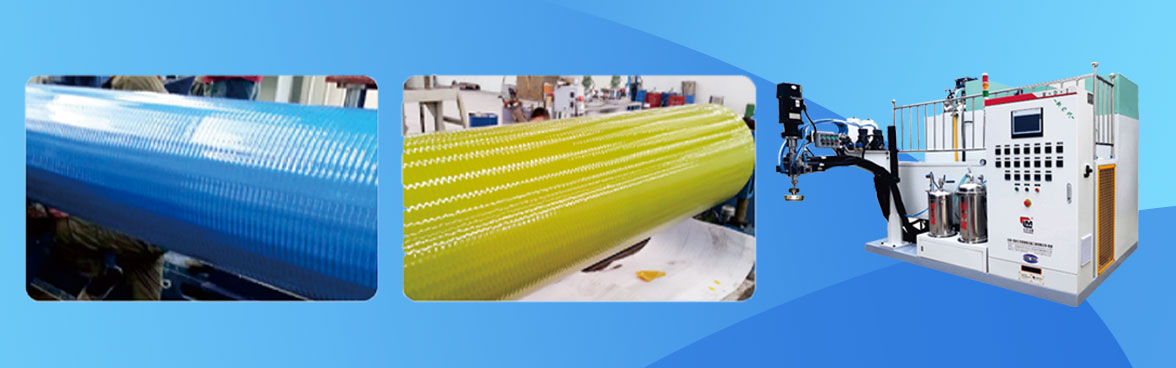

A final highlight is Feilong’s wide-hardness compatibility technology. By precisely adjusting the ratio between prepolymer and chain extender, the system can produce elastomers ranging from Shore A20 to A95, covering a full spectrum of applications—from medical-grade soft rollers to heavy-duty mining wheels.

From Mining Machinery to Cold Chain Logistics: The Invisible Power of “Chinese Elasticity”

Feilong’s breakthroughs are transforming heavy industries. In a large coal mining project, polyurethane rollers produced with Feilong equipment (1.2 m diameter, 8 tons per wheel) achieved 1.5× the service life of imported products, saving ¥260,000 per machine annually. The nanostructured SiO₂-enhanced polyurethane achieved a tear strength of 140 kN/m, far exceeding the industry benchmark of 90 kN/m.

Meanwhile, Feilong’s medical applications are setting new standards. A customized surgical table silent wheel achieved <65 dB noise, ISO 10993 biocompatibility certification, and exceptional resistance to wear and chemicals—ideal for use in Class 100,000 cleanrooms.

Domestic Substitution Accelerates Amid 7–8% Annual Growth

By 2025, China’s polyurethane elastomer market will reach ¥14 billion, yet 60% of high-end equipment remains import-dependent. Feilong offers equal or superior performance at only 60% of the price of imported machines. One automotive component manufacturer reported a 40% reduction in initial investment, 22% lower energy consumption, and a 1.8-year investment payback after switching to Feilong equipment.

Industry reports confirm that smart manufacturing is the new trend. Feilong’s Industry 4.0 intelligent equipment, equipped with IoT modules, enables remote diagnostics and process optimization. In one tire manufacturing case, product yield rose from 89% to 98.5%, generating over ¥10 million in annual revenue growth.

As “Made in China 2025” continues to advance, Feilong Polyurethane Equipment stands at the forefront of high-end manufacturing innovation—rewriting the narrative of China’s technological independence.

Source: Feilong Polyurethane Equipment Co., Ltd. Official Website; 2025 Polyurethane Elastomer Casting Equipment Industry Research Report