As energy costs continue to rise and building energy efficiency standards become increasingly stringent, a material is reshaping the insulation industry with an unstoppable momentum — it is polyurethane thermal insulation foaming material. In this wave of innovation, Feilong Polyurethane Machinery and Equipment, like a precise engine, provides core power for the ultimate performance of the material, turning efficient insulation from a concept into a tangible reality.

I. Excellent Performance of Polyurethane Thermal Insulation Foaming Materials: Why Can It Lead the Industry?

1. Superb Heat Insulation Capacity: The "Ultimate Barrier" for Heat

Its internal structure with a closed - cell rate of over 90%, like countless independent small insulation chambers, can minimize heat transfer caused by air convection. Authoritative tests show that its thermal conductivity can be as low as 0.018 - 0.025W/(m·K), far exceeding that of traditional insulation materials. Under the same insulation requirements, the thickness can be reduced by 30% - 50%.

2. Excellent Mechanical Properties: The Perfect Balance Between Lightweight and Sturdiness

It weighs only 30 - 60kg per cubic meter, but can withstand a compressive strength of 150 - 300kPa. Even in the environment of long - term load - bearing of building exterior walls or vibration of industrial equipment, it can maintain stable shape and avoid insulation failure due to deformation.

3. Reliable Flame Retardant Performance: Double Protection for Safety and Insulation

By adding environmentally friendly composite flame retardants such as magnesium hydroxide and nano - diatomite, it can easily meet the B1 - level flame retardant standard. When exposed to fire, it can quickly form a carbonized layer to inhibit the spread of flames, adding a safety barrier for buildings and industrial places.

II. Wide Application Scenarios: The "All - round Player" from Construction to Industry

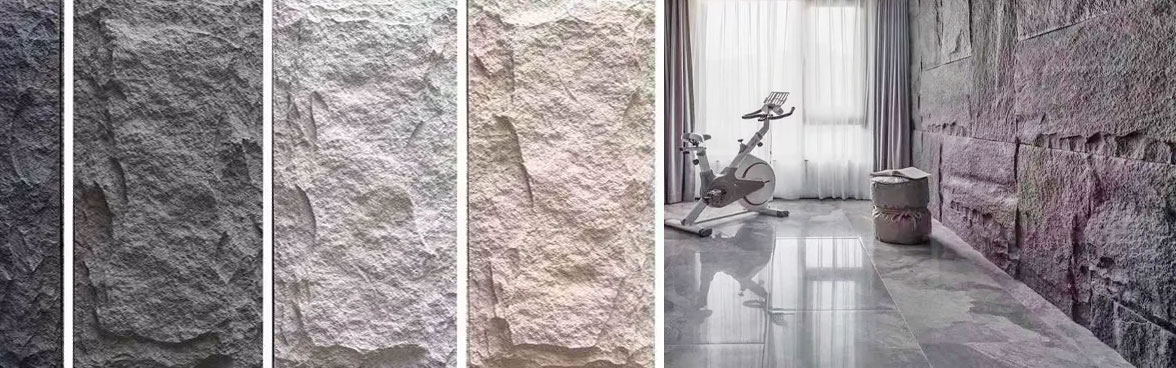

1. In the construction field, when used in external wall insulation systems, it can control indoor temperature fluctuations within ±2℃, reducing air conditioning and heating energy consumption by more than 30% every year.

2. In the industrial field, when wrapping a steam pipeline with a diameter of 1 meter, each 100 - meter pipeline can save about 50 tons of standard coal every year, which is especially suitable for the insulation of storage tanks and pipelines in chemical, electric power and other industries.

III. Preparation Method of Polyurethane Thermal Insulation Foaming Materials: How Are High - quality Materials "Born"?

1. Raw Material Preparation: Precise Proportioning is the Basis of Quality

Component A (resin phase) needs to be mixed with raw materials such as epoxy resin, polyether polyol and modified expanded perlite in strict accordance with the formula to ensure uniform dispersion of each component; Component B (isocyanate phase) should control the purity and moisture content, and the proportioning error between the two should be controlled within ±1%.

2. Mixing Reaction: The "Wonderful Moment" of Chemical Reaction

Inject components A and B into the mixing device in proportion. Under high - speed stirring (with a rotation speed of up to 2000 - 3000r/min), isocyanate and polyol quickly undergo an addition reaction, and at the same time, carbon dioxide gas is released, making the mixture gradually expand to form foam.

3. Molding and Curing: The "Transformation" from Foam to Material

The foamed material undergoes preliminary curing in the mold for 20 - 30 minutes, and then is left to stand in an environment of 25 - 35℃ for 24 - 48 hours to complete full curing, finally forming a polyurethane insulation material with stable structure and excellent performance.

IV. Feilong Polyurethane Machinery and Equipment: The "Unsung Hero" in Preparing High - quality Materials, What Are Its Core Advantages?

1. Precise Metering System: "Digital - level" Control with Proportioning Error ≤ 0.5%

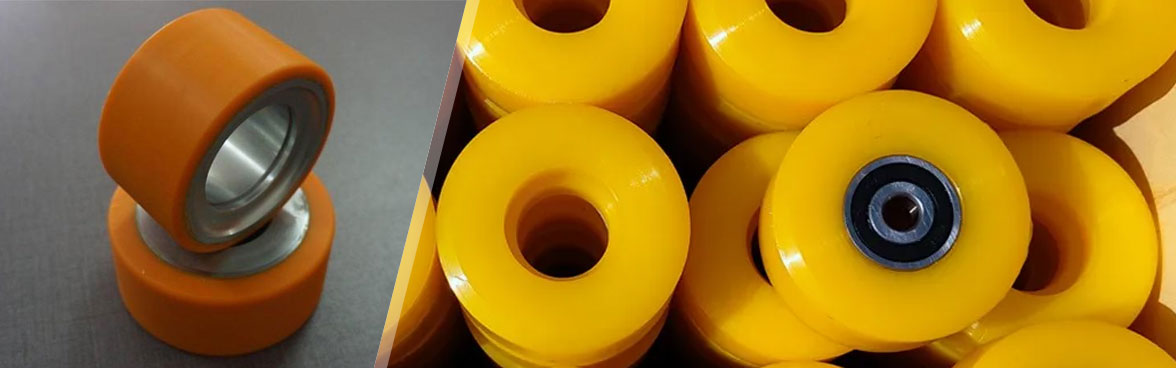

It adopts imported high - precision low - speed gear pumps, combined with intelligent flow sensors, to monitor and adjust the delivery volume of components A and B in real time, ensuring precise control within the weight ratio range of 1:1 to 1.6, and ensuring the stability of material performance from the source.

2. Efficient Mixing Link: Realizing "Molecular - level" Integration Within 3 Seconds

Equipped with a patented high - shear mixing head, it generates strong turbulence through a special blade structure, enabling the two components to achieve microscopically uniform mixing within 3 seconds, avoiding local performance defects caused by uneven mixing.

3. Reliable Pouring Head Design: "Failure - free Guarantee" for Continuous Production

The specially designed double mechanical seal structure can withstand a working pressure of 10 - 15MPa, completely solving the problems of air leakage and material backflow common in traditional equipment, enabling the equipment to run continuously for more than 8 hours without failure, and increasing production efficiency by 20%.

4. Precise Temperature Control: "Escort" for the Reaction

The material tank is equipped with an independent electric heating and water circulation temperature control system, which can stably control the raw material temperature at 20 - 30℃ with a temperature control error of less than ±2℃, ensuring uniform reaction speed and avoiding inconsistent foaming density caused by temperature fluctuations.

5. Wide Applicability: One Equipment, Meeting Multiple Needs

Whether it is rigid polyurethane foam for building insulation, semi - rigid foam for cold storage insulation, or flexible foam for seat filling, Feilong Polyurethane Machinery and Equipment can easily achieve it through parameter adjustment, meeting the diversified production needs of different industries.

V. Conclusion: Choose Feilong Polyurethane Machinery and Equipment to Start the "Efficient Era" of Insulation Material Production

The excellent performance of polyurethane thermal insulation foaming materials is inseparable from the support of advanced preparation equipment. Feilong Polyurethane Machinery and Equipment, with its precise metering, efficient mixing, reliable operation and wide applicability, has become the best choice for producing high - quality polyurethane insulation materials.

Choosing Feilong Polyurethane Machinery and Equipment is not only choosing a set of equipment, but also choosing an efficient, stable and low - cost production mode. Let us work together to promote the green upgrading of the insulation industry with high - quality polyurethane insulation materials and advanced production equipment, and contribute to energy conservation and sustainable development.