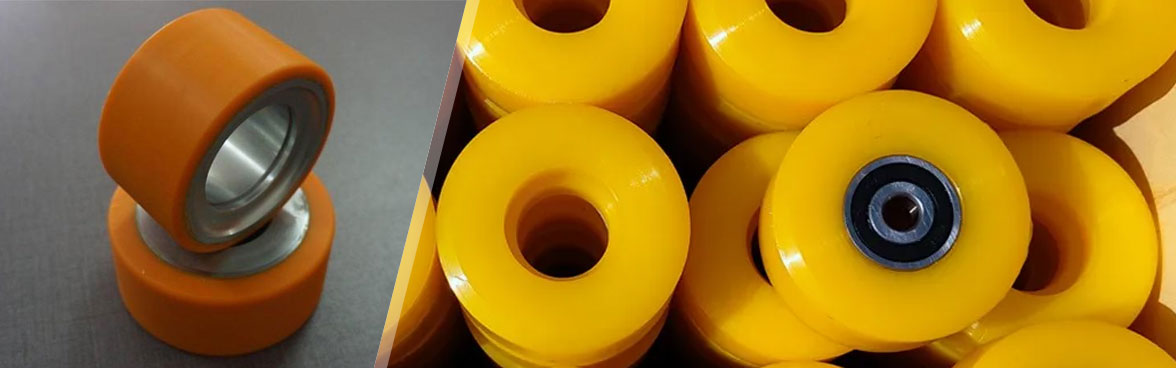

In industries such as rail transit, construction machinery, and heavy-duty vehicles, polyurethane saddle blocks play a critical role as load-bearing and vibration-damping components. Thanks to their excellent shock absorption, wear resistance, and mechanical strength, PU saddle blocks are widely used in key connection and support structures.

However, for many polyurethane manufacturers, stable and efficient mass production of saddle blocks remains a persistent challenge. Complex formulations, irregular geometries, and extremely high requirements for density uniformity and mechanical consistency mean that even minor process deviations can result in increased scrap rates, costly rework, and delayed customer deliveries.

Key Manufacturing Pain Points in PU Saddle Blocks

1. Extremely Tight Ratio Control Requirements

PU saddle blocks typically use two- or multi-component polyurethane systems. A deviation of more than ±1% in the A/B ratio can lead to incomplete curing or mechanical properties falling outside specification. Traditional equipment relying on manual adjustment or mechanical metering struggles to maintain long-term precision.

2. Air Entrapment and Incomplete Filling

Saddle blocks often feature deep cavities, thin walls, or reinforcing ribs. If injection pressure, material temperature, or flow rate are not precisely controlled, defects such as bubbles, shrinkage voids, or short shots easily occur—directly compromising structural integrity and surface quality.

3. Long Changeover Times and Limited Flexibility

Customer requirements vary widely in terms of dimensions, hardness, and color. Frequent product changes demand fast setup and high flexibility. Equipment without rapid response and parameter memory significantly reduces overall equipment efficiency (OEE).

Feilong Polyurethane Equipment: Precision-Driven Solutions for Saddle Block Production

As a national high-tech enterprise, Feilong integrates 54 patented technologies into its polyurethane equipment design. Its polyurethane elastomer casting machine series demonstrates clear advantages in saddle block applications:

High-Precision Closed-Loop Metering System

Driven by servo motors combined with high-sensitivity mass flow meters, Feilong’s system achieves dynamic A/B ratio control accuracy of ±0.5%. This ensures consistent chemical reactions across batches and significantly improves the stability of mechanical properties.

Intelligent Temperature Control & Vacuum-Assisted Casting

For complex mold geometries, the equipment features multi-zone independent temperature control with ±1°C accuracy, and optional vacuum degassing modules. Air is effectively removed from the mixed material before casting, dramatically reducing internal defects and increasing first-pass yield by up to 15% or more.

Modular Design with Rapid Mold Change Capability

Casting heads, material tanks, and mold tables adopt standardized quick-connect structures. Combined with an HMI that stores multiple process recipes, switching between different saddle block specifications takes only 10–15 minutes, greatly enhancing production flexibility and capacity utilization.

More Than Equipment: A Process-Oriented Partnership

Feilong believes that the true value of high-end equipment lies not only in hardware performance, but in how well it integrates with the customer’s manufacturing process. Guided by a “product-oriented development” philosophy, Feilong provides saddle block manufacturers with one-stop support, including equipment selection, mold compatibility recommendations, on-site commissioning, and operator training.

Conclusion

In today’s increasingly competitive polyurethane market, efficiency and quality are the lifelines of manufacturing enterprises. If you are still struggling with high scrap rates, delayed deliveries, or frequent downtime in saddle block production, the solution may not be more labor—but a professionally engineered intelligent casting system.

Make equipment understand your process. Bring production back to efficiency.

Feilong Polyurethane Equipment empowers your saddle block manufacturing to achieve high yield, low failure rates, and long-term stability.