How to Select Polyurethane (PU) Product Production Lines for Automotive Interior Decoration - Professional Guide from Feilong Polyurethane Machinery Equipment Factory

Introduction

In the automotive interior manufacturing field, polyurethane (PU) materials are widely used in components such as seats, headrests, armrests, and dashboard due to their lightweight, high resilience, and wear resistance. As a core supplier of polyurethane production equipment, Feilong Polyurethane Machinery Equipment Factory, leveraging years of technical expertise, provides efficient and stable PU production line solutions for global customers.

This article will combine the technical features of Feilong equipment to elaborate on how to select the appropriate automotive interior polyurethane production line, covering equipment selection, process optimization, cost control, and industry application cases.

Key requirements for the production of automotive interior polyurethane products

Before selecting the production line, it is necessary to clarify the product type and industry requirements:

Common PU interior products: seat foam, steering wheel covering, door panel filling, ceiling sound-absorbing layer, etc.

Industry standards:

Physical properties: density, resilience, fatigue resistance (for example, seats need to meet 100,000 durability tests).

Environmental requirements: low VOC (volatile organic compounds), no harmful solvents (in line with EU ELV, Chinese GB/T 27630, etc.).

Production efficiency: OEMs usually require cycle matching (for example, forming a set of seat foam every 2 minutes).

2. Analysis of Core Equipment of Feilong Polyurethane Production Line

Feilong Polyurethane Machinery Equipment Factory offers modular production line solutions, which can be flexibly configured according to customer requirements.

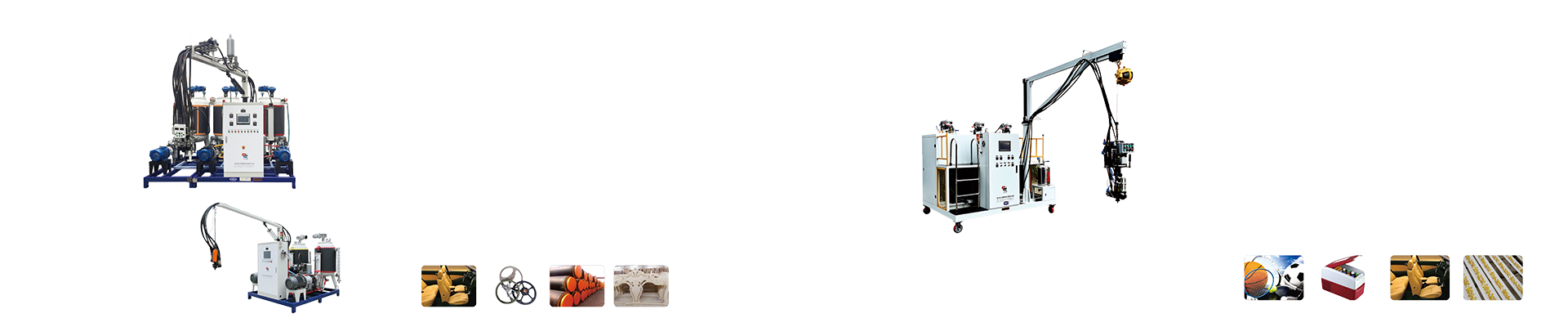

(1) High-pressure foaming machine system

Technical advantages:

Uses imported German metering pumps, with a mixing accuracy of ±1%, ensuring stable PU material ratio.

Can be adapted to various formulas (such as high resilience, slow resilience, flame-retardant polyurethane).

Applicable products: Large-volume foaming parts for automotive seats, headrests, etc.

(2) Low-pressure injection machine

Technical advantages:

Suitable for filling complex molds (such as partial foaming of door panels, instrument panels).

Feilong patented low-pressure mixing head, reducing material splashing and lowering waste rate.

Energy-saving design: 15% to 20% more energy-efficient than traditional equipment.

(3) Automated mold system

Optional configuration:

Rotary multi-station molds: Improve production efficiency (such as a 4-station system can achieve continuous production).

Quick mold changing device: Adapt to multi-variety small-batch orders (mold replacement completed within 30 minutes).

(4) Post-processing equipment

Curing drying tunnel: Precise temperature control, shortening PU curing time.

Cutting/trimming machine: Numerical control water jet or circular knife cutting, meeting high-precision cutting requirements.

3. How to select the appropriate production line configuration?

(1) Choose based on product type

| Product type | Recommended equipment combinations | Feilong's typical customer cases |

| Seat foam | High-pressure foaming machine + rotating mold + curing line | A seat supplier for a Chinese new energy vehicle manufacturer |

| Wristrest cover | Low-pressure injection machine + precision mold + automatic demolding system | An export-oriented steering wheel manufacturer for Europe |

| Door panel filling layer | Low-pressure foaming machine + multi-chamber mold + rapid mold change | A door panel supplier for Japanese brands |

2) Select based on production capacity requirements

Small production line (for testing / small batch):

Single-component foaming machine + manual molds, investment approximately 500,000 - 1,000,000 RMB.

Medium-sized production line (for regional suppliers):

High-pressure foaming machine + 2-station molds, annual production of 100,000 pieces, investment 2,000,000 - 5,000,000.

Large production line (for OEM support):

Fully automatic high-pressure line + robot picking, cycle time ≤ 90 seconds, investment 8,000,000 - 15,000,000.

(3) Select according to environmental protection requirements

Basic plan: Standard foaming machine (requires ventilation treatment).

High-end plan: Feilong Green PU production line (closed raw material transportation + VOC recovery system), compliant with EU REACH regulations.

4. Competitive advantages of the Feilong polyurethane production line

Localized services: 24-hour technical response, spare parts supply cycle shorter than that of imported brands.

Customized development: Supports customers' special requirements (such as flame retardant, antibacterial PU formula adaptation).

Intelligent monitoring: Optional IoT data collection system for real-time monitoring of equipment status and product quality.

5. Success Case: Cost Reduction and Efficiency Enhancement Practice of an Automobile Seat Factory

Background: The client originally used imported equipment, which was costly and had a long maintenance period.

Feilong Solution:

Replaced with the Feilong High-Pressure Foaming Machine + domestic molds, saving 40% of equipment investment.

By optimizing the raw material mixing parameters, the scrap rate was reduced from 5% to 1.2%.

Outcomes: The investment cost was recovered within 6 months, and the factory successfully expanded to orders from the second main manufacturer.

6. Decision-making process for selecting the Feilong production line

Demand analysis: Determine product type, production capacity, and budget.

Technical alignment: Feilong engineers provide process verification (samples can be sent for trial production).

Solution customization: Sign a plan for equipment configuration and delivery.

Training and after-sales: On-site installation and commissioning + Operator training.

Conclusion

When choosing an automotive interior polyurethane production line, one needs to take into account the product characteristics, production capacity goals, and compliance requirements comprehensively. Feilong Polyurethane Machinery Equipment Factory, with its cost-effective equipment, flexible customization capabilities and local service advantages, has become a reliable partner for many suppliers both at home and abroad.