In heavy industries such as mining, metallurgy, and coal, the efficiency and durability of screening equipment directly determine production continuity. Traditional metal screen panels typically last less than three months, while clogging issues require weekly shutdowns for cleaning. Excessive noise levels further burden operators.

Feilong Polyurethane Equipment has developed a new generation of polyurethane screen panels, achieving 8–10 times the lifespan of metal panels and boosting screening efficiency by 30%.

Industry Pain Points: The “Triple Shackles” of Traditional Screen Panels

Heavy-duty screening environments have long been plagued by three major issues:

- Short Lifespan: Steel screens last only 2–3 months under high-impact wear. Stainless steel options cost twice as much as polyurethane but offer just one-third of the lifespan.

- Efficiency Bottlenecks: Moist fine materials (such as coal or mineral sludge) easily stick and clog metal panels, cutting efficiency by over 40% and often requiring manual cleaning.

- Energy and Environmental Burden: Metal panels are dense (7.85 g/cm³), increasing equipment load by 20–30% and generating noise levels over 90 dB—well above the industrial safety limit of 85 dB.

These issues increase annual maintenance costs by 30% and cut effective production time by 15%, becoming key obstacles to cost reduction and efficiency.

Technical Breakthroughs: Four Core Innovations

Feilong polyurethane screen panels solve these challenges through material, structural, and process innovations:

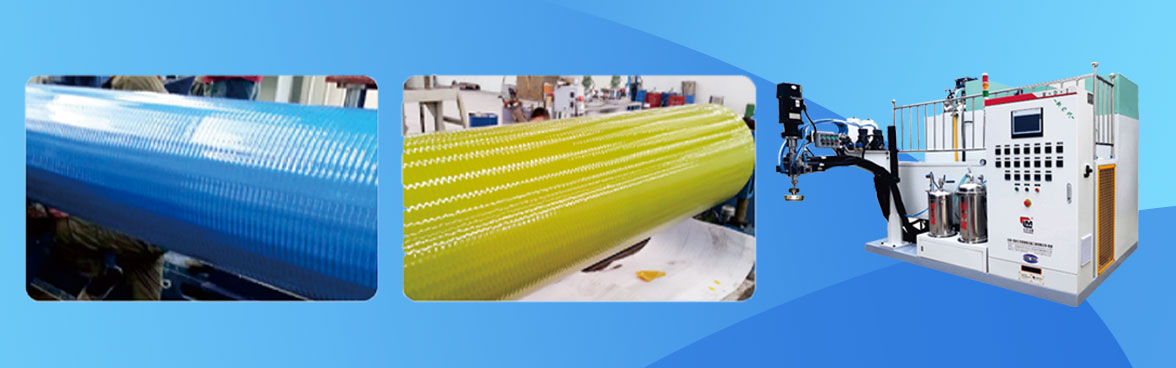

- Material Revolution: Polyurethane Elastomer + Steel Cable Reinforcement Advanced polyurethane elastomer combined with a high-strength steel wire skeleton prevents delamination under long-term dynamic loads. Wear resistance is 3–5 times that of steel and 5+ times that of rubber. In iron ore grading applications, service life exceeds 8–10 years, far outlasting metal screens (8–12 months). Optimized formulations achieve Shore A hardness 80–95, tensile strength ≥45 MPa, and tear strength ≥35 kN/m, meeting extreme impact requirements.

- Structural Innovation: 140° Tapered Holes + Dynamic Self-Cleaning Tapered hole design (140°) and polyurethane’s water-shedding properties improve throughput of moist materials by 50%. Self-cleaning action under vibration reduces clogging to below 0.5%, solving the common “half blocked in 3 days” issue of metal screens. Precision molding ensures ≤0.1 mm hole tolerance, with sizes ranging 0.1–170 mm to meet both fine dewatering (0.5–3 mm) and coarse grading (up to 170 mm).

- Installation Revolution: Wedge-Lock Fast Replacement Unique wedge-lock design enables fast installation across circular, linear, and high-frequency screens. Replacement time per panel is cut from 1 hour to just 10 minutes. Modular design supports partial replacement, reducing maintenance costs. Lightweight advantage: density 1.32 g/cm³, reducing panel weight by 70% compared to metal. This cuts equipment load by 20–30% and saves 15–20% in annual energy use.

- Environmental Upgrade: Noise Reduction and Safety Polyurethane’s elasticity and damping lower operational noise by 5–20 dB. Field tests show levels under 75 dB, meeting environmental standards. Non-toxic, odor-free, corrosion-resistant, and flame-retardant properties allow applications in pharmaceuticals and food processing.

Proven Applications Across Industries

Feilong polyurethane screen panels are already deployed at scale in mining, coal, and construction sectors:

- Mining & Metallurgy: At one iron ore mine, screen panel lifespan extended from 2 months to 2 years, reducing downtime by 120 hours annually and improving overall efficiency by 40%.

- Coal Processing: In coal washing plants, clogging rates dropped from 35% to below 5%, improving screening efficiency by 30% and increasing coal recovery by 2%, adding millions in value annually.

- Construction & Hydropower: In sediment separation, lifespan reached 3 years—four times longer than rubber—cutting maintenance costs by 60%.

The panels handle a full particle size range (0.1–170 mm), ensuring stable performance in both dry screening (e.g., ore classification) and wet screening (e.g., sludge dewatering).

Conclusion: Innovation Reshapes Industry Competitiveness

While traditional screening solutions remain stuck in low-value competition—focused on cost and frequent replacement—Feilong Polyurethane Equipment delivers performance-driven innovation. With 8–10x longer service life and 30% higher efficiency, Feilong’s screen panels transform screening machines into profit-generating units rather than cost centers.