In the beauty market, cotton pads are a fast-growing segment with an annual growth rate of 18%. Yet, over 40% of consumer complaints focus on poor absorbency, lint shedding, and deformation. Behind this paradox lies a key truth: the quality revolution of cotton pads begins with breakthroughs in production equipment.

From Materials to Processes: Solving Three Major Quality Issues

“Producing cotton pads with traditional equipment is like opening a blind box—you never know what you’ll get. The same formula can pass one day and fail the next,” admitted the production director of a leading beauty brand in an industry interview. At the heart of this issue are two challenges: insufficient precision in material ratios and unstable foaming processes. Feilong Polyurethane Equipment has transformed this uncertainty into precision manufacturing through three core technological breakthroughs.

On the materials side, its patented “Polyurethane Cotton Pad and Preparation Method” provides a precise solution: blending polyether polyol DDL-4000D and POP45G at a 3:7 ratio, combined with 0.6 parts of an amine-tin composite catalyst. This enhances the cotton pad’s water absorption to over 200% (compared to about 150% in conventional products), while maintaining 90% rebound resilience after wetting.

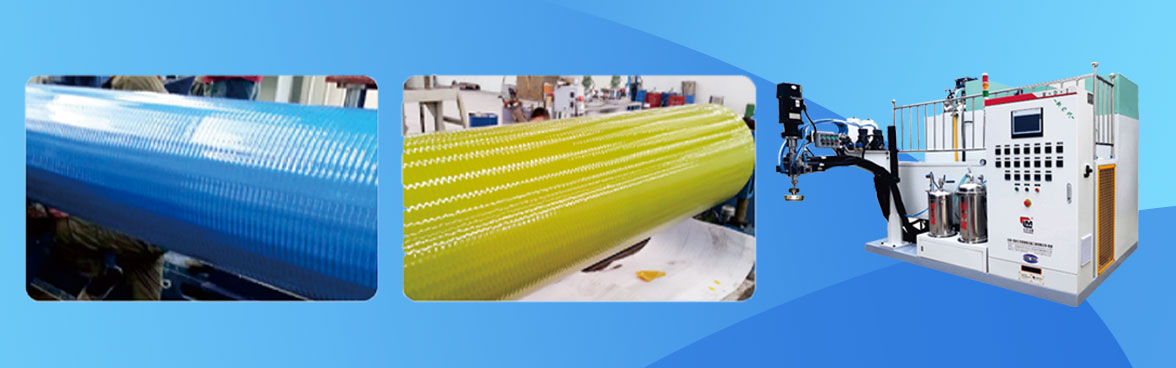

Process innovation is even more disruptive. Traditional foaming machines often suffer from uneven mixing, leading to pore size deviations of up to ±30 μm. Feilong’s self-developed “Precision Micro-Foaming Test Machine,” equipped with dynamic pressure compensation technology, controls pore size within the 50–80 μm range with 95% uniformity.

Finally, intelligent control serves as the “last safeguard” for consistent quality. The ERP-based production management system monitors raw material temperature (±1℃ accuracy), mixing pressure (0.3–0.5 MPa), and curing time (3–5 minutes with smart adjustment). This raises the product pass rate from the industry average of 85% to over 98%.

The Era of Precision Manufacturing: Big Market Logic in Small Equipment

“Don’t underestimate a simple cotton pad—its production technology rivals that of auto parts,” noted a standing director of the China Polyurethane Industry Association during a site visit to Feilong. This “over-engineering” reflects a broader transformation: China’s manufacturing sector is shifting toward “hidden champions.” Behind the booming beauty market lies a much larger demand for precision manufacturing equipment—from medical dressings to high-end foams, from electronic encapsulation to rail transit cushioning materials.

Feilong Polyurethane Equipment has set a model for this shift: focusing on niche applications, building barriers with patented technologies, and improving efficiency with smart systems. According to Qichacha, 38% of the company’s 55 patents relate to precision manufacturing, and R&D has consistently accounted for more than 8% of investment in the past three years.

When a consumer picks up a soft and skin-friendly cotton pad at a beauty counter, they may not realize the decades of dedication behind it. Yet Feilong Polyurethane Equipment—with 55 patents and a 99% customer satisfaction rate—demonstrates the resilience of Chinese intelligent manufacturing in even the smallest “capillaries” of industry. Looking ahead, with the integration of AI and IoT technologies, Feilong is poised to deliver even more breakthroughs.