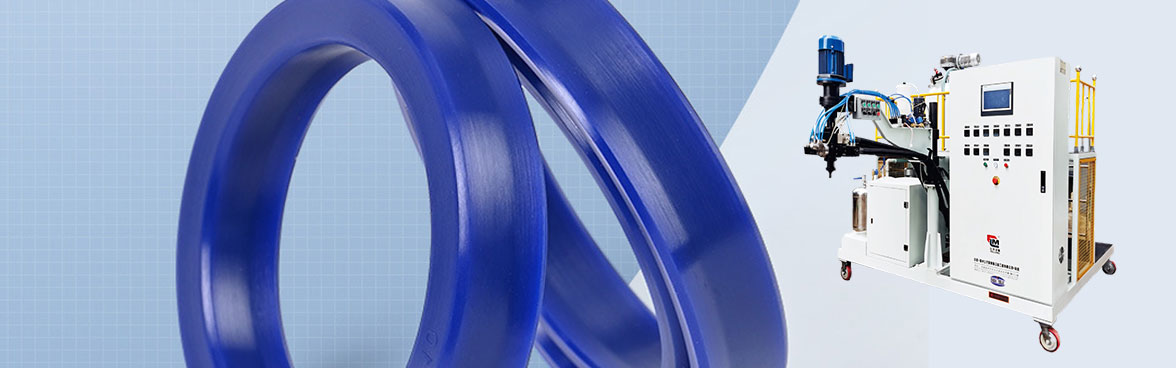

In industrial manufacturing, seals may be small, but they play the critical role of a “leak-proof guardian.” Their quality directly affects equipment efficiency, safety, and service life. However, recurring problems in conventional seal production often become a roadblock for companies seeking to improve quality and efficiency. If you are facing these challenges, it’s time to consider Feilong Polyurethane Equipment.

Producing seals may look simple, but it actually demands extremely high precision in both process and equipment stability. Many companies using traditional methods encounter the following issues:

- Unstable performance – Inaccurate raw material ratio control (errors exceeding 1%) causes significant hardness deviations within the seal. Some end up too brittle and break easily, while others are too soft and fail to seal properly. In high-pressure, high-temperature environments, seals can fail quickly—for example, an engine oil seal that doesn’t meet hardness standards can lead to oil leakage and equipment breakdown.

- Short lifespan and high wear – Crude mixing devices result in uneven material dispersion, leaving hidden bubbles or layers inside the seal. This drastically reduces wear resistance and tear strength. For instance, hydraulic cylinder seals in construction machinery may wear out over 30% faster due to these internal defects, leading to frequent replacements and costly downtime.

- Dimensional deviations and surface defects – Low-precision moving systems and poorly designed pouring heads can cause size tolerances to exceed ±0.5mm, making seals incompatible with mating parts. In severe cases, overheated or leaking pouring heads can cause surface defects such as missing material or burrs, pushing defect rates above 15%.

- Poor adaptability to diverse needs – Traditional equipment is rigid in process control and difficult to adjust. When producing custom-shaped seals (such as curved automotive window seals) or varying hardness levels (30A–95A), many factories either cannot produce them at all or have very low yield rates—losing valuable orders.

- Weak environmental resistance and frequent after-sales complaints – Seals with insufficient high/low-temperature resistance and poor aging performance can crack at -20°C or become brittle after just three months of outdoor sun exposure. This leads to oil or water leakage, increasing after-sales costs and damaging the company’s reputation.

Choose Feilong Polyurethane Equipment for “Zero Headache” Seal Production

With years of industry experience, Feilong Polyurethane Equipment focuses on innovation and process upgrades to solve seal manufacturing pain points at the root—delivering real competitive advantages to manufacturers.

- High-precision control for consistent performance Equipped with imported metering pumps with a precision of 5‰, Feilong ensures raw material ratio errors stay at an industry-leading low. Every batch of seals delivers consistent hardness and elasticity. Specially designed mixing devices achieve complete blending—no bubbles, no layering—improving wear resistance by 30% and tear strength up to 45MPa, extending product lifespan by 2–3 times.

- Stable production with immediate cost and efficiency gains Our self-developed floating mechanical seal pouring head can operate for 8 hours continuously without overheating or material leakage. Combined with imported moving systems, we achieve ±0.1mm dimensional tolerances and flawless surface finishes—reducing defect rates by 90%. Automated program control minimizes manual intervention, boosting production efficiency by 40% and adding over 2,000 units per day per line.

- Flexible adaptation to diverse orders Capable of producing square, round, and custom-shaped seals, Feilong’s equipment allows one-click parameter adjustments for hardness from 30A (soft, medical-grade) to 95A (high-strength industrial-grade). Whether it’s automotive filter seals, hydraulic cylinder oil seals, or waterproof gaskets for food machinery, we meet client requirements with precision—ensuring no orders are missed.

- Extreme durability with zero after-sales worries Feilong seals maintain stable elasticity between -40°C and 120°C, pass 1,000-hour ozone resistance tests with no cracking, and outperform industry standards in aging resistance. Ideal for outdoor heavy machinery and EV battery packs, they can operate reliably for over 5 years—drastically reducing after-sales complaints and boosting brand reputation.

Choosing Feilong Means Choosing “Peace of Mind + Profitability”

Seal quality reflects a company’s supply chain competitiveness. Most seal production problems stem from outdated equipment technology. Feilong’s strength lies in leveraging advanced technology to shift you from “reactively fixing problems” to “proactively creating value.”

Over 2,000 companies have upgraded their production with Feilong Polyurethane Equipment, raising seal pass rates to 99% and increasing customer repurchase rates by 60%.

Contact us now for your exclusive seal production solution—and make your products stand out in the market!