The Importance of Connecting Pretreatment and Casting in Metal Insert Polyurethane Wheel Production

Pretreatment lays the foundation for the casting process; inadequate treatment leads to weak bonding between metal inserts and polyurethane. The casting process, on the other hand, determines the wheel’s final shape and performance. Only a seamless connection between these two steps ensures product quality.

Optimization 1: Timing Linkage Between Automated Pretreatment Line and Casting Machine

Metal insert pretreatment involves degreasing, sandblasting, and gluing. Traditional manual transfer often causes long intervals between processes, reducing the insert’s surface activity.

Feilong Polyurethane Equipment’s intelligent pretreatment linkage line uses a PLC control system to form closed-loop timing control among the degreasing tank, automatic sandblasting chamber, adhesive curing box, and casting machine. Sandblasted inserts are automatically transferred to the gluing station by a robotic arm. After gluing, they enter a constant-temperature curing channel (temperature accuracy ±1℃). When the adhesive layer reaches the optimal activation state, the equipment automatically triggers the casting machine’s raw material preheating program, shortening the interval between the two processes to less than 3 minutes and significantly improving bonding strength.

Optimization 2: Dynamic Matching of Sandblasting Parameters and Casting Pressure

Metal inserts of different materials require differentiated sandblasting parameters, and the surface roughness after sandblasting directly affects polyurethane casting pressure.

Feilong Polyurethane Equipment’s sandblasting-casting linkage system collects insert surface roughness data in real-time via sensors (accuracy 0.1μm) and automatically feeds it back to the casting machine’s pressure adjustment module. For example, when the roughness of carbon steel inserts after sandblasting reaches Ra5.0μm, the system automatically adjusts the casting pressure to 8MPa to ensure raw materials fill the pits. For aluminum alloy inserts (recommended Ra3.2μm), the pressure is automatically reduced to 5MPa to avoid deformation. This mechanism increases the peel strength of the bonding surface by over 20%.

Optimization 3: Cooperative Control of Adhesive Curing Temperature and Raw Material Casting Temperature

The curing degree of the adhesive and the polyurethane casting temperature must be strictly matched: insufficient curing causes decomposition due to high-temperature raw materials, while excessive curing leads to loss of reaction activity.

Feilong Polyurethane Equipment’s multi-stage temperature control system enables cooperative temperature adjustment between the curing box and the casting machine. At the end of adhesive curing (80℃), the system preheats raw materials to 95℃ in advance (error ≤±2℃) to maintain a 15℃ temperature difference. After the insert enters the casting station, the raw material temperature accurately drops to 90℃ within 3 seconds, forming an optimal reaction window. This technology improves the product’s temperature resistance to -40℃~120℃, meeting the needs of harsh working conditions.

Optimization 4: Intelligent Calibration of Insert Positioning Accuracy and Casting Trajectory

Positioning deviations of metal inserts cause uneven polyurethane distribution and even insert loosening.

Feilong Polyurethane Equipment’s visual positioning-robot casting system identifies the position of the insert’s reference hole via a 20-megapixel industrial camera. Coordinate data is transmitted to the six-axis casting robot in real-time, which automatically calibrates the trajectory to ensure raw material filling deviation ≤0.5mm. Meanwhile, the 3D flow monitoring module detects the casting amount in real-time; if the deviation exceeds 3%, it immediately 补上 the casting to avoid defective products due to material shortage.

Optimization 5: Traceability Linkage Between Post-treatment Aging and Preceding Processes

The aging of wheels after demolding must match pretreatment and casting parameters to precisely control performance.

Feilong Polyurethane Equipment’s full-process data traceability system records 18 key parameters for each batch (e.g., sandblasting time, adhesive model) and automatically generates a post-aging plan. For products with high-temperature adhesives (cured at 90℃) and high casting pressure (≥7MPa), the system recommends post-aging at 110℃ for 20 hours, increasing the cross-linking degree of polyurethane molecules by 15%. For products under normal working conditions, conventional parameters (100℃×16 hours) are used. This mode ensures performance consistency and reduces energy consumption.

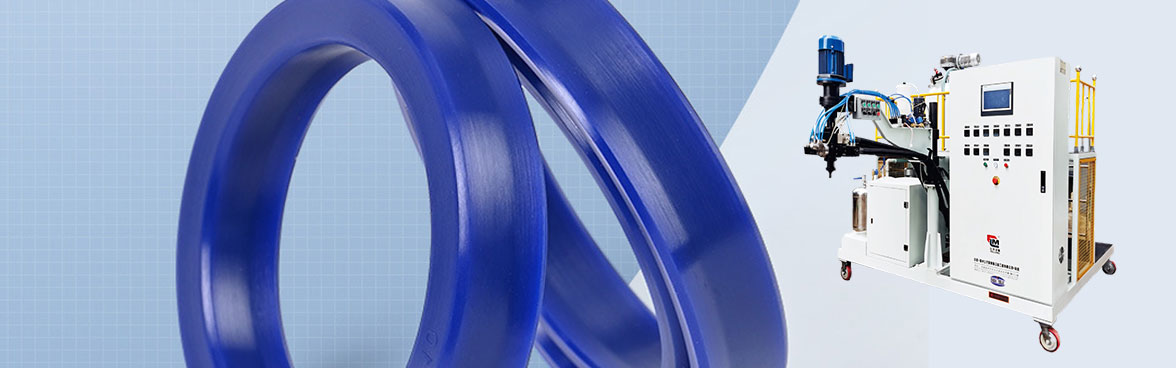

Conclusion: Feilong Polyurethane Equipment Empowers Metal Insert Polyurethane Wheel Production

In summary, Feilong Polyurethane Equipment achieves in-depth collaboration between pretreatment and casting processes through an intelligent control system. It increases the production qualification rate from 85% to 99% and extends service life by over 30%, making it the preferred solution in fields such as logistics transportation and engineering machinery.