Synthetic leather, as an important alternative to natural leather, is widely used in various industries, particularly in automotive interiors. However, traditional equipment for producing synthetic leather has several pain points that limit product quality, production efficiency, and the industry’s sustainable development. Feilong Polyurethane Machinery has developed a solvent-free synthetic leather coating machine designed to address these challenges and meet the high demands of the automotive interior sector.

1. Pain Points of Traditional Synthetic Leather Production

1.1 Environmental Issues

Traditional production processes often involve volatile organic solvents (VOCs) such as toluene. The United Nations Environment Programme has noted that industrial solvent exposure poses significant health risks, while also contaminating water and soil. Treating waste solvents adds high costs to production.

1.2 Quality Deficiencies

- Poor coating uniformity: Difficulty in precisely controlling coating volume and speed may affect product appearance and physical properties.

- Unsatisfactory touch and texture: Common issues include stiffness, excessive softness, surface roughness, and stickiness.

- Unstable performance: Environmental factors can significantly influence water resistance, oil resistance, and other performance indicators.

1.3 Low Production Efficiency

- Outdated equipment with low automation levels, heavily reliant on manual operation, slows production.

- Component quality and assembly precision are often lacking, leading to higher fault rates, increased maintenance costs, and reduced product stability.

2. High Demand for Synthetic Leather in Automotive Interiors

2.1 Wide Applications

Synthetic leather is extensively used in automotive seats, door panels, dashboards, and steering wheel covers. Since the 1970s, automotive brands have applied synthetic leather in seating, and its usage share in interiors continues to grow.

2.2 Significant Advantages

- Cost-effectiveness: Compared to genuine leather, synthetic leather is less expensive to produce, helping manufacturers control costs.

- Excellent performance: PU synthetic leather offers high strength, thin yet elastic texture, softness, smoothness, good breathability, and moderate waterproofing. It maintains tensile and flexural strength at low temperatures, resists light aging and hydrolysis, is easy to clean, and has good flame retardancy and heat dissipation.

- Sustainability: As a relatively eco-friendly choice, synthetic leather alleviates the strain on genuine leather resources and reduces environmental pollution from leather production, while maintaining good durability and water resistance.

2.3 Rapid Market Growth

According to QYResearch, the global automotive synthetic leather market is expected to grow steadily through 2029. Rising consumer demand for attractive, eco-friendly interiors is making synthetic leather increasingly important in the sector.

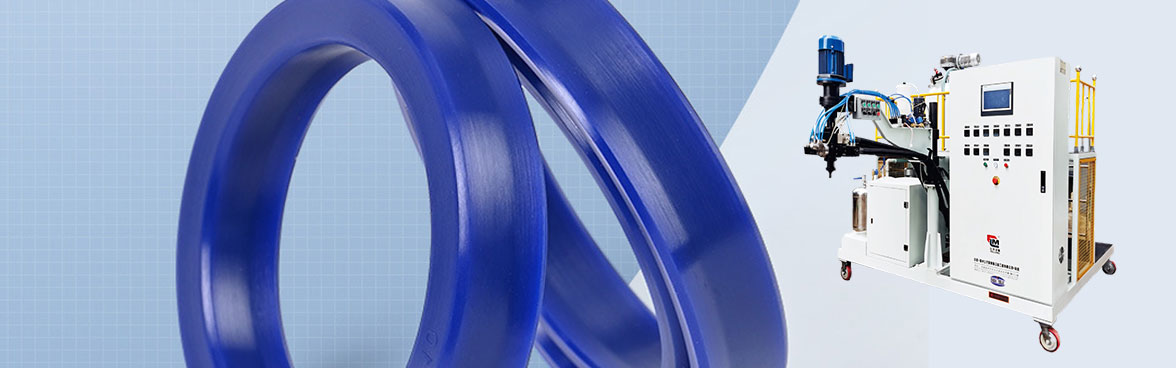

3. Feilong Polyurethane Machinery’s Industry Expertise

With over 20 years in the polyurethane equipment sector, Feilong has a team of engineers specializing in chemical, mechanical, electrical, and computer control fields. The company has an R&D center, process technology department, and product testing facilities, enabling it to design and prototype custom polyurethane equipment. Its solvent-free synthetic leather coating machine combines innovative technology and optimized processes to meet the automotive interior industry’s stringent demands.

4. Innovations of the Solvent-Free Synthetic Leather Coating Machine

4.1 Enhanced Environmental Performance

- Utilizes solvent-free technology, eliminating the need for VOC-heavy solvents like toluene and DMF, drastically reducing emissions.

- Avoids costly solvent recovery systems and minimizes hazardous waste, dust, and wastewater.

- Equipped with negative pressure dust control and waste recovery systems, improving material utilization and meeting international environmental standards such as REACH and ROHS.

4.2 Superior Product Quality

- High-precision coating control: Servo-driven metering pumps, high-accuracy mass flow meters, and PLC control systems ensure precise, stable resin application, producing uniform coatings with improved texture and color consistency.

- Stable process control: Closed-loop feedback regulates pressure and temperature in the mixing chamber, ensuring thorough crosslinking of polyurethane resin and reducing performance instability caused by environmental variations.

- Optimized texture and feel: The solvent-free process avoids coating damage from solvent evaporation, enabling fine surface smoothness, natural leather-like touch, and elasticity without stickiness or stiffness.

4.3 Greatly Improved Production Efficiency

- Continuous high-speed production: Automated feeding, laminating, and winding systems boost production speed and shorten cycles.

- Quick changeovers: Supports rapid mold and parameter adjustments to minimize downtime.

- Smart maintenance: PLC systems monitor equipment in real time, detect anomalies, and trigger alarms to reduce interruptions. Modular design facilitates maintenance, extending component lifespan and lowering repair costs.

- Reduced manual intervention: Automated tension control with ultrasonic sensors ensures smooth substrate feeding, cutting dependence on manual adjustments.

4.4 Lower Costs

- Reduced investment and operating costs: Lower energy consumption with far-infrared heating and hot-air circulation, and no need for solvent recovery equipment.

- Higher product value: Eco-friendly, premium-quality solvent-free synthetic leather commands better market positioning, particularly in automotive interiors.

- Versatile production: Compatible with multiple substrates (e.g., polyester film, fiberglass cloth), enabling production of diverse products on a single line, improving equipment utilization, and adapting quickly to market changes.

5. Conclusion

Limitations of traditional synthetic leather production have hindered its broader adoption in high-demand fields such as automotive interiors. The industry’s shift toward higher quality and sustainability requires better products and manufacturing technologies.

Feilong Polyurethane Machinery, leveraging decades of expertise, has developed its solvent-free synthetic leather coating machine to address environmental, quality, efficiency, and cost challenges. This innovation enhances product performance, meets automotive industry requirements, and supports sustainable development, making it an ideal choice for advanced synthetic leather production.