The global automotive polyurethane bump stop market is expanding steadily at a compound annual growth rate of 3.6%. Behind this growth lies the increasing demand for higher shock absorption capabilities in new energy vehicles—battery pack weight has increased load requirements by 30%, while traditional rubber bump stops struggle to perform under harsh working conditions ranging from -40°C to 120°C. The Feilong Polyurethane Microcellular Elastomer Casting Machine redefines manufacturing precision for automotive buffer components with military-grade production standards. Featuring a metering accuracy of ≤5‰ and temperature control precision of ±2°C, it has helped domestic manufacturers capture 31% of the NEV buffer market share.

From Laboratory to Production Line: Reshaping Buffer Manufacturing Standards

Intelligent Temperature Control System: Precise Control Over Every Degree

In automotive buffer production, a 1°C temperature fluctuation can cause a deviation of more than 5% in compression deformation rate. Feilong Polyurethane employs a dual closed-loop intelligent temperature control system that uses PT100 sensors to monitor temperatures in three key zones—material tanks, pipelines, and the mixing head—in real time. With PID algorithms dynamically adjusting heating power, the system maintains temperature fluctuations within ±2°C, a significant improvement compared to the ±5°C seen in conventional equipment. This ensures that NDI-based prepolymer maintains stable viscosity within its 80–125°C reaction window.

Multi-Component Switching: Formula Changeover in Just 30 Seconds

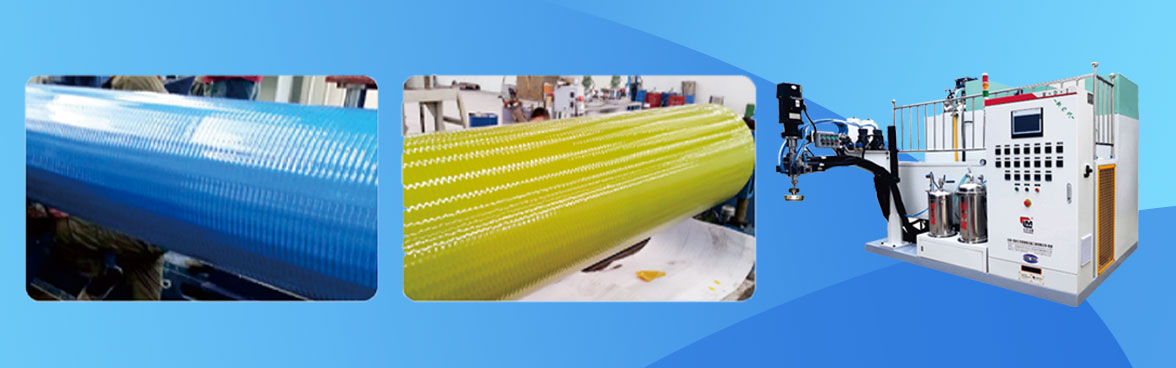

Modern automotive buffers require gradient mechanical performance, shifting from single-density designs to multi-layer energy absorption. This means achieving hardness transitions from Shore A 60 to 80 within a single product. Feilong’s casting machine features a 12-component independent material supply system. Each tank is equipped with a high-temperature stainless steel liner (up to 300°C resistance) and a vacuum dehydration unit. Servo-driven precision gear pumps deliver formula ratios adjustable between 100:(8–16) with high accuracy, enabling rapid, automated material switching in as little as 30 seconds.

Revolutionary Metering Accuracy: Military-Grade Precision Within 5‰

In 2015, a military industry project required metering repeatability under 5‰ over 100 cycles of buffer casting—yet no supplier could meet this demand. Feilong’s R&D team adapted metering technologies from aerospace fuel injection systems, combining a ceramic plunger metering pump with a laser flow sensor to achieve ultra-fine material control at as low as 0.1 g/s flow rates. During automotive buffer trials, the system demonstrated exceptional consistency—over 5,000 parts produced continuously within 24 hours, weight deviation remained within ±0.3%, outperforming the industry average tolerance of ±1%.

Material Performance Breakthrough: Full-Process Optimization from Formulation to Finished Product

Rebound resilience and tear resistance are critical metrics for evaluating buffer durability. Feilong, together with the Chinese Academy of Sciences, developed an NDI-based microcellular elastomer system, enabling precise foaming density control between 0.6–0.8 g/cm³ via intelligent casting. Performance data shows buffer blocks produced using this process achieve rebound resilience of 59–66% and tear strength of 45–54 kN/m—20% higher abrasion resistance compared to MDI systems. In extreme low-temperature testing at -40°C, the buffers retained 85% of their original performance even after 100,000 impact cycles.

Intelligent Production Management: Eliminating Data Silos with ERP Integration

In traditional buffer production lines, incorrect material ratios often cause defect rates exceeding 10%. Feilong’s casting machine integrates industrial IoT modules to collect real-time operational data, which is then synchronized to an ERP platform for predictive analytics. The system automatically alerts operators to activate vacuum dehydration when raw material moisture exceeds 0.05%, and triggers predictive maintenance before metering pump pressure fluctuation occurs—significantly reducing downtime and scrap rates.

Conclusion

As the automotive industry accelerates toward lightweight and intelligent vehicle design, polyurethane buffers are evolving from simple shock absorbers to intelligent structural components capable of housing sensors and energy-absorbing designs. Equipped with 55 patented technologies and CE/ISO certifications, Feilong Polyurethane Equipment showcases China’s innovation capabilities in advanced manufacturing. In the global reshaping of automotive supply chains, choosing Feilong is not only a cost advantage—but a strategic move to grow alongside the new era of Chinese intelligent manufacturing.