Medical-Grade Polyurethane Casting Machine: Precision and Reliability for Healthcare Manufacturing

In the medical field, polyurethane materials are valued for their superior biocompatibility and mechanical properties, widely used in medical devices, wound dressings, and surgical applications.

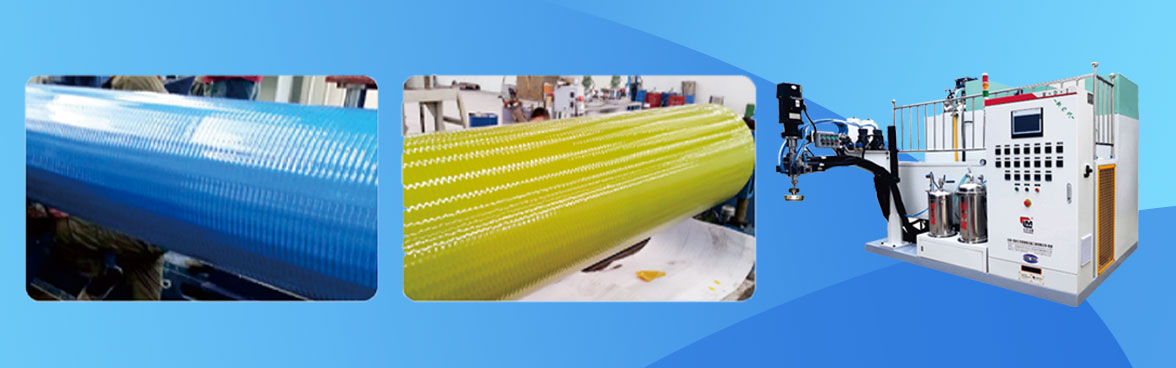

Feilong Polyurethane Equipment has developed a dedicated medical-grade polyurethane elastomer casting machine, featuring a flow-compensated anti-clogging continuous casting system. The patented anti-blocking mixing head and floating mechanical seal design on the stirring shaft effectively prevent backflow and material residue during high-speed rotation, ensuring a consistent and stable material ratio.

The equipment’s core technological strengths lie in three major areas:

- Precision metering pump group with deviation-coupled fluid ratio control – Incorporating a proportional factor and speed compensator, it achieves highly accurate material proportioning and synchronized pump control.

- Intelligent metering calibration and encoder closed-loop control – Guarantees dosing accuracy within 0.5% and allows remote parameter setting and fault diagnosis.

- Dynamic pressure balancing for material tanks – Uses digital image processing to analyze material flow behavior, ensuring precise control between casting and return pressure.

In terms of performance, the system achieves a total discharge accuracy of ≤0.5%, ratio repeatability ≤0.8%, and temperature control within ±2 °C — fully meeting the stringent quality standards for medical products.

Feilong’s medical-grade polyurethane equipment has passed EU CE and ISO 9001 certifications, providing dual assurance for safe and compliant production.

Hydrophilic Cotton Continuous Production Line: High-Efficiency Nonwoven Fabric Solution

As a highly absorbent functional material, hydrophilic cotton is widely used in hygiene products and medical dressings. Feilong’s continuous production line for hydrophilic cotton integrates complete nonwoven manufacturing processes — from fiber opening, carding, stretching, hydroentangling, dewatering, and drying to automated control — forming a comprehensive, energy-efficient production system.

Key advantages include high productivity, low energy consumption, and consistent quality.

The line uses PLC modular control with a 10-inch touchscreen interface, supporting timed and quantitative pouring, automatic cleaning, and air flushing functions.

In process innovation, the line applies Feilong’s multi-component elastomer equipment technology, supporting up to 12 raw material groups for precise mixing — meeting diverse functional product demands. Equipped with a vacuum degassing system and automatic nitrogen compensation, it ensures bubble-free materials and enhanced product stability.

Technical Innovation System: Four Dimensions of Core Competitiveness

Feilong Polyurethane Equipment has established a full-process ERP production management system, enabling intelligent and highly automated manufacturing.

Its technical advantages are reflected in four key dimensions:

- Comprehensive quality control standards that exceed customer expectations.

- Limitless functionality expansion driven by in-house software development capabilities.

- Multi-dimensional technical support from interdisciplinary expert teams.

- Rapid response service mechanism ensuring timely solutions.

Feilong’s R&D center houses advanced facilities — CAD design labs, pneumatic and hydraulic testing platforms, metrology and electrical test centers — and over 50 sets of precision machining equipment. Through collaborations with institutions such as the Shanghai National Technology Transfer Center, Chinese Academy of Sciences, Feilong has developed multiple first-in-China polyurethane equipment systems, reinforcing its leadership in innovation.

Application Expansion: From Medical Health to Industrial Upgrading

Feilong Polyurethane Equipment’s technologies serve nine major industries, including defense research, mining, rail transit, wheel manufacturing, consumer and industrial goods, marine, foam products, and home furnishings.

In the medical sector, its equipment produces catheters, wound dressings, surgical sutures, and more.

In hydrophilic cotton applications, end products include baby diapers, adult incontinence pads, feminine hygiene products, and medical wipes.

Feilong’s hydrophilic cotton products feature excellent absorption and quick-drying properties, exceeding GB/T 21655 standards:

- Water absorption rate: > 200%

- Drip diffusion time: < 3 seconds

- Capillary height: > 10 cm

- Evaporation rate: > 0.18 g/h These parameters ensure top performance for premium hygiene and medical use.

Future Outlook: Dual-Drive of Intelligence and Sustainability

In line with global polyurethane industry trends, Feilong Polyurethane Equipment is advancing toward high-end, intelligent, and green manufacturing.

On the intelligent front, the company integrates Industrial Internet technologies, using sensors and big data for predictive maintenance and operational optimization.

On the green manufacturing side, its solvent-free polyurethane production systems significantly reduce VOC emissions, aligning with international environmental standards.

As a leading representative of China’s polyurethane equipment industry, Feilong Polyurethane Equipment continues to embody the spirit of “Feilong Intelligent Manufacturing.”

Through ongoing innovation and service excellence, it delivers advanced polyurethane production solutions worldwide — driving the industry toward sustainable, high-quality growth.