In 2025, the global air purifier filter market is projected to exceed USD 30 billion, with demand in the commercial and medical sectors growing by over 25% annually. In this wave of industry upgrading, Feilong Polyurethane Equipment’s integrated filter seal strip (gasket) production line is driving a new phase of innovation in the filtration industry.

Technological Breakthrough: From Material to Process Innovation

Feilong’s advancements begin with solving the core pain points of filter sealing components.

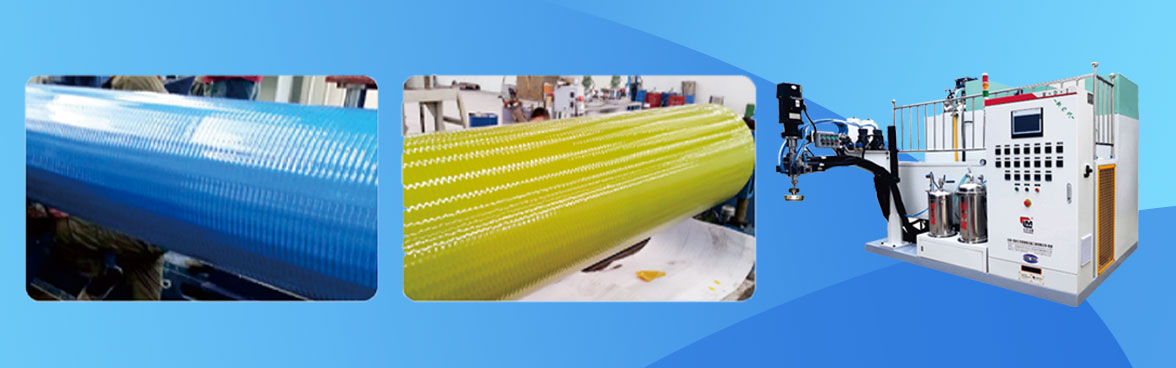

In traditional production, uneven pigment dispersion often limits product qualification rates to around 80%. Feilong’s patented pigment dispersion technology, built into its high-polymer polyurethane casting machine, adopts an arc-toothed ring and rotating shaft synergistic mixing structure to achieve micron-level uniform blending between pigment and raw polyurethane — boosting the qualification rate to 99%.

The high-precision metering pump system forms another core advantage. Using a deviation-coupled fluid proportioning control system with encoder-based closed-loop feedback, it maintains material ratio deviations within ±0.5%. On the fully automatic filter gasket casting machine, the X-Y axis profiling table enables precise pouring for circular, square, and irregular filter designs, increasing production efficiency fivefold compared to manual operation.

Intelligent production control further enhances cost efficiency. A full-process ERP management system monitors 28 key process parameters—including raw-material ratios, pouring temperature, and curing time—while the industry-specific software allows rapid switching between filter specifications, achieving high-flexibility smart manufacturing.

Market Insight: Equipment Value Under the Rise of Composite Filters

The global filter market is undergoing structural transformation.

According to GEP Research, composite filters integrating HEPA, activated carbon, and catalytic layers have risen from 28% of the market in 2023 to 41% in 2025. Feilong’s three-component pouring system perfectly matches this trend—achieving simultaneous, precise dosing of polyurethane elastomers, activated carbon granules, and antibacterial agents—delivering a one-stop sealing solution for composite filters.

The subscription-based service model is reshaping production demands. Over 31% of top brands now offer filter subscription plans, requiring manufacturers to support small-batch, multi-batch flexible production. Feilong’s modular equipment design allows quick switching between different gasket thicknesses (1–10 mm) and densities (0.3–0.8 g/cm³), reducing minimum order quantities to 500 units per batch—60% lower than the industry average—empowering SMEs to enter niche segments with agility.

Industry Transformation: How “Made in China” Reshapes Global Competition

As the Equipment Engineering Technology Sub-Center of the National Reaction Injection Molding Engineering Research Center, Feilong’s polyurethane filter seal strip equipment delivers twice the service life of local products in tropical climates thanks to its superior weather resistance.

Standardization has become a new competitive edge.

Feilong participated in drafting the “Polyurethane Filter Seal Equipment Group Standard”, officially implemented in 2025, which defines 12 key performance indicators—including pigment dispersion uniformity and thermal shock resistance—now incorporated into CE certification standards.

The company also accelerates green manufacturing transformation.

Through its end-to-end ERP-controlled production process, material utilization reaches 98% while energy consumption is reduced by 22%.

Amid global supply chain restructuring, Feilong’s polyurethane filter seal strip production line is breaking through traditional manufacturing limits.

With performance parameters from –60 °C cold resistance to 120 °C heat endurance, 8 N/cm adhesion strength, and ≤3% air-leakage rate, the equipment represents another milestone for Chinese precision manufacturing.

For air purifier manufacturers, choosing Feilong equipment is more than a production upgrade—it’s a strategic step to claim leadership in the next-generation filter market.