Introduction

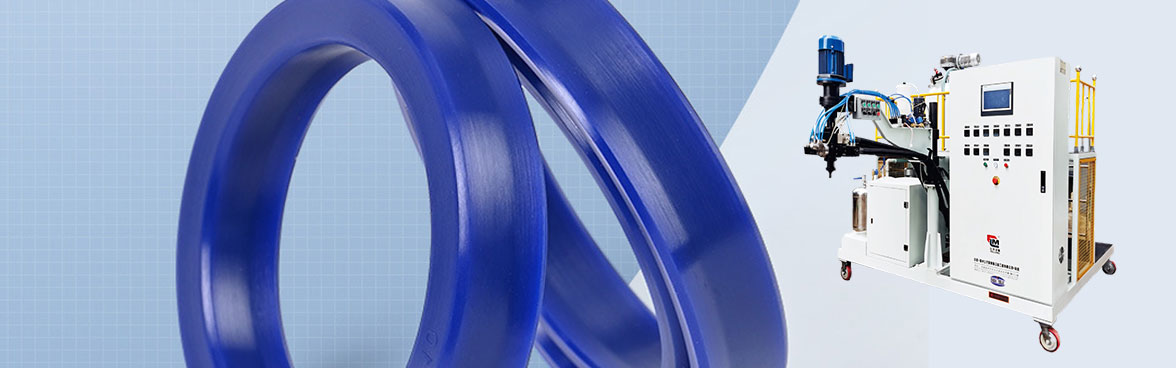

Automotive floor mats, as high-frequency used interior parts, directly impact the user experience. Persistent issues like degumming, slipping, pungent odors, and poor fit have long trapped manufacturers in a "high complaint rate + high rework rate" dilemma. Feilong polyurethane elastomer casting machines, with data-driven parameters, precisely address these four industry pain points, becoming a key tool for automakers to reduce costs and improve efficiency.

1. 0.5-0.8MPa Stable Pressure: Eliminating Degumming

- Problem: Traditional floor mats often degum due to insufficient bonding pressure (<0.3MPa) or excessive temperature fluctuations (over ±5℃), causing layer separation.

- Solution: Feilong’s closed-loop hydraulic system locks hot-pressing pressure at 0.5-0.8MPa, paired with ±1℃ temperature control (120-180℃), enabling molecular-level fusion between polyurethane and substrates (TPE, non-woven fabrics). A 15-30s intelligent pressure-holding process forms stable chemical bonds, achieving an interlayer peel strength of ≥3.5N/cm (75% higher than industry standards).

- Case: A parts manufacturer reduced degumming complaints from 15% to below 2% after adoption. The mats passed 500 cycles of -40℃ to 80℃ tests without issues, successfully entering major automakers’ supply chains.

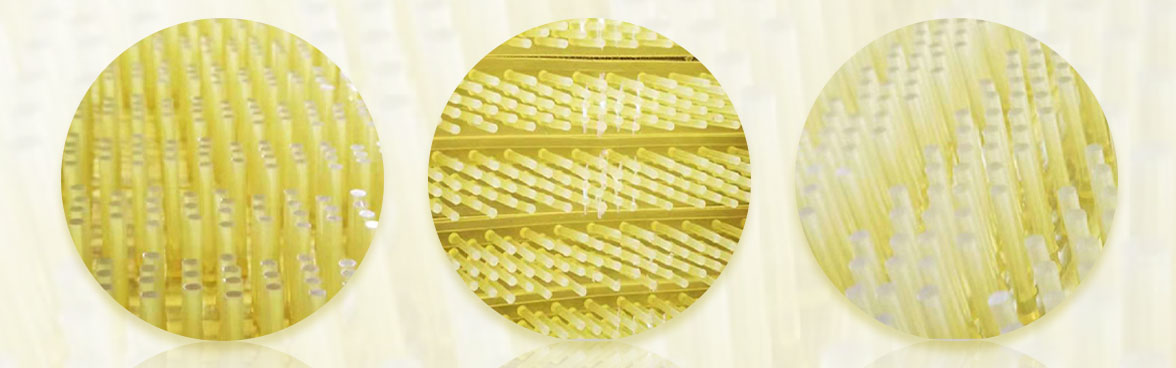

2. ±0.02mm Mold Precision: Enhancing Slip Resistance

- Risk: Slipping floor mats pose driving safety hazards.

- Solution: Feilong uses dual technologies:

- Result: Static friction coefficient reaches ≥0.6 (dry) and ≥0.5 (wet), exceeding the national safety standard of ≥0.4.

- Case: A high-end interior factory produced mats for luxury brands. The products remained stable in emergency braking simulations, securing million-level orders and industry endorsements.

3. Three-Level Control System: Eliminating Odors

- Source: Odors stem from excessive VOCs (volatile organic compounds).

- Measures:

- Case: A new brand marketed "baby-safe" mats using this technology, ranking top 3 in e-commerce categories with a 30% higher repurchase rate than peers.

4. ±1g Pouring Control: Achieving Precision Fit

- Demand: Custom floor mats require tight fit, testing equipment precision.

- Advantages:

- Case: A contract manufacturer reduced poor fit rates from 10% to below 3% for new energy vehicle mats, achieving 99% on-time delivery and extending contracts with automakers by 3 years.

Conclusion

While the industry relies on "experience," Feilong uses verifiable data—3.5N/cm peel strength, 0.02mg/m³ formaldehyde, ±0.02mm mold precision, and ±1g pouring control—to build trust. For automakers, choosing Feilong means securing "fewer complaints, higher efficiency, and stronger competitiveness."