In modern agricultural irrigation, the performance and compatibility of a polyurethane impeller for agriculture directly influence equipment efficiency, energy use, and service life. Leveraging advanced engineering and precision manufacturing, Feilong Polyurethane Equipment offers custom polyurethane impeller solutions tailored to different irrigation scenarios—ensuring durability, cost savings, and optimal performance.

Key Matching Factors for Agricultural Polyurethane Impellers

Agricultural irrigation conditions vary widely—water quality, equipment type, planting mode, and climate all demand specific irrigation pump impeller designs. Feilong’s approach involves in-depth field research, understanding polyurethane material properties, and optimizing each impeller’s material composition and structural design for maximum efficiency.

1. Customizing Material Performance for Different Water Sources

Water source characteristics determine the durability, wear resistance, and corrosion resistance needed in a farm irrigation pump impeller. Feilong’s material customization ensures each impeller meets exact field requirements.

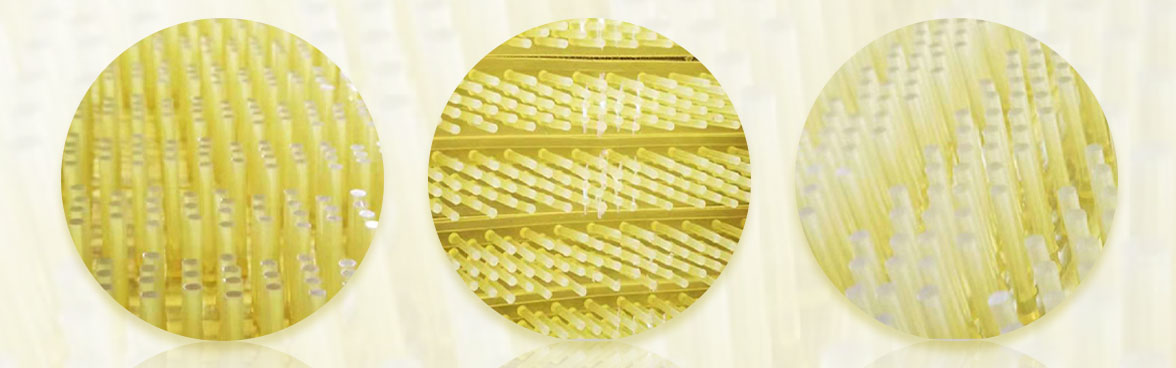

- Wear-Resistant Irrigation Impeller for High-Sediment Water In river-fed irrigation systems, sediment levels can reach 30–50 g/m³, sometimes over 60 g/m³. Feilong uses electromagnetic high-efficiency vibration mixing to evenly disperse silicon carbide particles into the polyurethane matrix. This achieves Shore hardness of 90–95A, forming an “anti-wear armor” ideal for abrasive conditions. In field tests on a corn farm with 40 g/m³ sediment, the wear-resistant polyurethane impeller ran for six months with only 0.15 mm blade wear—far outperforming conventional designs.

- Corrosion-Resistant Polyurethane Impeller for Complex Water Quality Tropical regions with high pesticide/fertilizer residues may have pH ranges from 5–9, while desert farming often faces alkaline water at pH 8.5–9.5. Feilong adapts molecular structures to resist acid or alkali corrosion, extending impeller lifespan in challenging chemical environments. Field data from vegetable farms show a 12-month corrosion-free operation—double that of nitrile rubber impellers.

2. Optimizing Structure for Equipment Conditions

Different irrigation pump types require different polyurethane impeller structures and parameters.

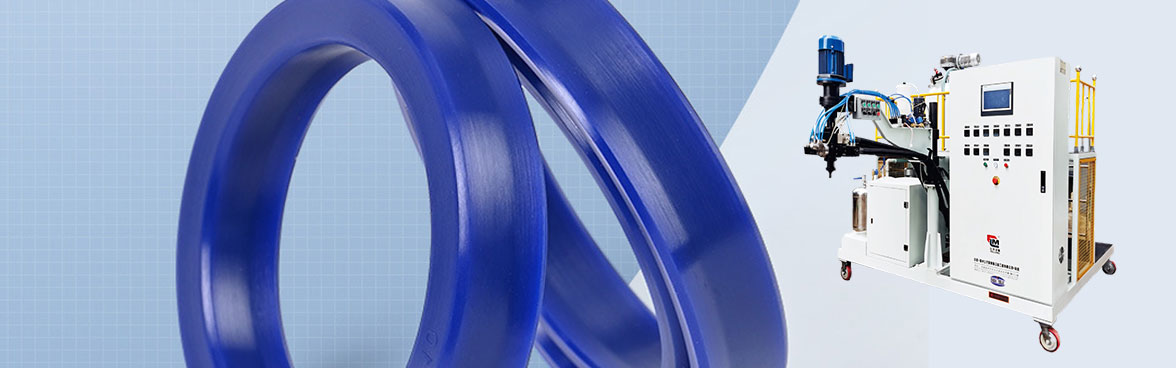

- Lightweight, Impact-Resistant Irrigation Pump Impeller for Mobile Systems Tractor-towed mobile pumps face frequent relocation and sudden starts/stops. Feilong uses controlled foaming to keep impeller density at 1.1–1.2 g/cm³—over 60% lighter than cast iron—reducing shaft load and fuel consumption. Unique molding raises impact resistance to 30–50 kJ/m², two to three times stronger than nylon impellers.

- High-Efficiency Polyurethane Impeller for Fixed Pump Stations For deep-well or pipeline-based systems, precision shaping at micron-level ensures smooth flow channels, minimizing turbulence and energy loss. This structural optimization boosts pump efficiency by 5–8%, helping large farms cut operational costs.

3. Adapting to Planting Modes and Extreme Climates

- Durable Polyurethane Impeller for Large-Scale Farming Farms spanning thousands of acres require impellers with long service life. Feilong enhances crosslink density to increase fatigue resistance, allowing over 12 months of continuous use.

- Irrigation Pump Impeller for Extreme Climates In cold climates, Feilong’s mold temperature control ensures polyurethane resists brittleness at –10°C, keeping irrigation reliable in winter. For tropical areas, UV-resistant additives extend impeller life by 50% under intense sunlight.

Conclusion

By integrating water source analysis, equipment adaptation, planting mode considerations, and climate resilience, Feilong Polyurethane Equipment delivers precision-matched polyurethane impellers that enhance efficiency, reduce maintenance, and extend service life. From wear-resistant irrigation impellers for high-sediment rivers to lightweight impellers for mobile pumps and UV-protected designs for tropical climates, Feilong offers complete, high-performance solutions for global agriculture.