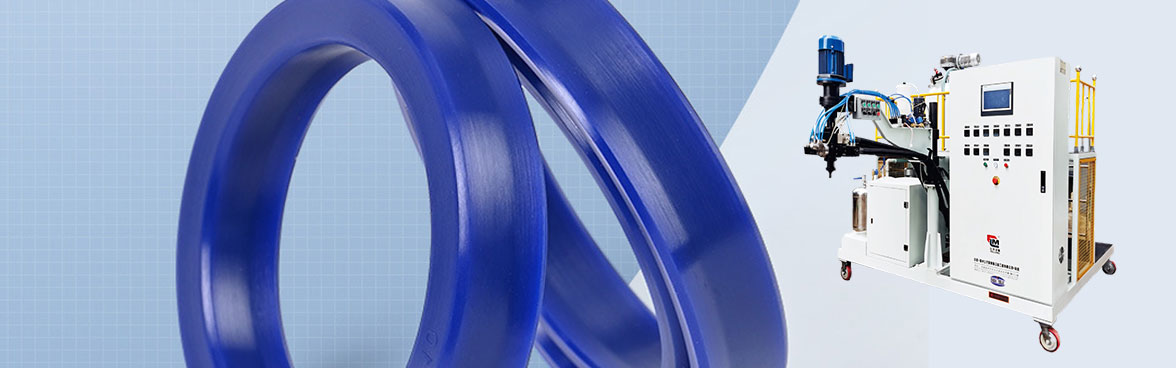

In printing production, the wear resistance and chemical resistance of brushes directly impact equipment operating efficiency and the stability of print quality. Many printing companies producing their own polyurethane brushes face recurring problems such as “frequent replacements” and “rapid performance degradation,” often linked to equipment selection.

The working environment of printing machine brushes is demanding, and technical limitations in production equipment may lead to substandard performance:

Frequent Replacements Due to Poor Wear Resistance

Conventional casting equipment, with limited mixing precision, may result in uneven molecular crosslink density in polyurethane, causing localized wear on the brush surface. Some printing plants report that brushes made using traditional equipment require more frequent replacement during high-speed printing. Downtime not only affects productivity but uneven wear can also cause fluctuations in printing pressure, compromising print quality.

Performance Degradation from Poor Chemical Resistance

Solvents in inks—such as ethyl acetate and ethanol—continuously affect polyurethane brushes. If temperature control precision is insufficient, brushes may not fully cure, leaving residual components that swell when exposed to solvents. This can cause issues like “ink leakage” and “dirty plates,” reducing production quality.

Batch Inconsistency Leading to Management Challenges

Small and medium-sized printing companies often use manual equipment without online detection or closed-loop control, leading to hardness variations in brushes from the same batch. This forces operators to adjust each batch individually, increasing labor costs and making it difficult to ensure consistent print quality. Quality fluctuations may even cause production losses.

The root of these problems lies in traditional equipment’s inability to precisely control the entire chemical reaction process of polyurethane from liquid to solid. Feilong Polyurethane Equipment, through process innovation, helps solve these issues.

Three-Tier Control System to Enhance Wear and Chemical Resistance

1. Raw Material Mixing Stage: Building the Foundation for Wear Resistance

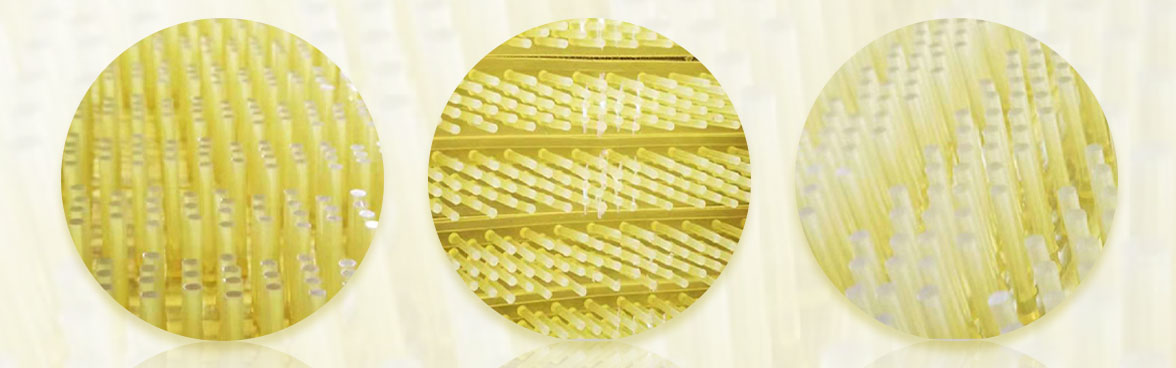

Polyurethane wear resistance depends on uniform molecular crosslink density, which requires high mixing precision:

- Dynamic Mixing in High-Pressure Casting Machines Using high-pressure impingement mixing to micro-particleize raw materials, combined with servo metering pumps, helps control the precision ratio of isocyanates and polyols. Tests show that brushes produced with this equipment exhibit better wear resistance than those made with conventional equipment, as the uniform molecular structure reduces localized failure.

- Nano-Filler Dispersion for Reinforcement For high-wear applications (e.g., corrugated printing), a specialized dispersion module can evenly distribute reinforcing fillers such as carbon black. These fillers improve wear resistance, extending brush service life.

2. Curing and Molding Stage: Strengthening Chemical Resistance

Complete curing is essential for polyurethane to resist solvent attack. Feilong equipment uses precise temperature control to achieve this:

- Stepwise Curing via Intelligent Mold Temperature Controllers For commonly used polyester-type polyurethane brushes, the equipment can pre-set multi-stage heating curves to control temperature differences at each phase. This process improves curing degree, lowers free isocyanate content, and enhances solvent resistance. Printing plants report that brushes made this way last longer in solvent-rich environments.

- Vacuum Degassing to Prevent Bubble Formation Inadequate degassing in traditional equipment can leave bubbles inside brushes, creating solvent penetration pathways. Feilong’s vacuum degassing unit reduces bubbles, increases brush density uniformity, and minimizes solvent erosion risks structurally.

3. Post-Processing Stage: Ensuring Dimensional Stability

Both wear and chemical resistance must be reflected in stable dimensional accuracy, which requires precision finishing:

- Micron-Level Finishing with Precision Grinders Feilong equipment ensures minimal radial runout, maintaining consistent contact pressure between brush and printing roller. This reduces localized overload that accelerates wear, while a smooth surface minimizes ink residue and chemical corrosion.

- Online Quality Control Integrated laser dimension measurement and hardness testing modules periodically sample brushes, with real-time data feedback to the control system. This helps adjust process parameters and reduce hardness variations within a batch, improving consistency in print quality.

Conclusion: From “Passive Replacement” to “Proactive Control”

For printing companies, the pursuit of better brush performance is essentially the pursuit of production stability. Feilong Polyurethane Equipment transforms “experience-based” manufacturing into “parameter-controlled” production, making brush wear and chemical resistance more controllable and stable.

Choosing the right equipment not only reduces replacement costs but also improves print quality consistency—strengthening a company’s market competitiveness. For printing enterprises with in-house brush production, Feilong offers not just equipment, but a complete performance assurance system from raw materials to finished products.