The polyurethane wheel market is set to surpass the 10-billion-yuan mark, with the elevator wheel segment leading in growth. Behind these numbers lies the industry’s urgent demand for highly durable, low-noise wheels. Traditional rubber wheels wear out five times faster than polyurethane wheels under multi-ton loads, and each replacement costs about 30% of the wheel’s purchase price in labor alone. Leveraging its national-level R&D platform, Feilong Polyurethane Equipment is driving the industry’s shift from “frequent replacements” to “long-term operation” with its polyurethane elevator wheel production line solutions.

How Polyurethane Elevator Wheels Are Changing Industry Standards

In the machine rooms of commercial complexes, maintenance records show that polyurethane guide wheels installed in 2023 show only minor wear to date, while rubber wheels previously required replacement every eight months on average. The difference stems from the molecular chain structure of polyurethane—within the Shore hardness range of 83–95A, its Akron abrasion value is over 60% lower than that of rubber wheels, while wheel deformation under multi-ton loads is controlled within 0.3 mm.

The environmental advantages are even more striking. An epoxy flooring inspection report from a high-end office building revealed that after one year of elevator operation with polyurethane wheels, no carbon black marks were left on the floor. By contrast, adjacent freight elevators with rubber wheels produced visible black streaks. Following the enforcement of the EU REACH directive, orders for Feilong’s solvent-free polyurethane wheels grew 40% year-on-year. With weather resistance spanning –40℃ to 120℃, these wheels also solve the long-standing problem of winter hardening and cracking.

The Technology Behind the Smart Production Line

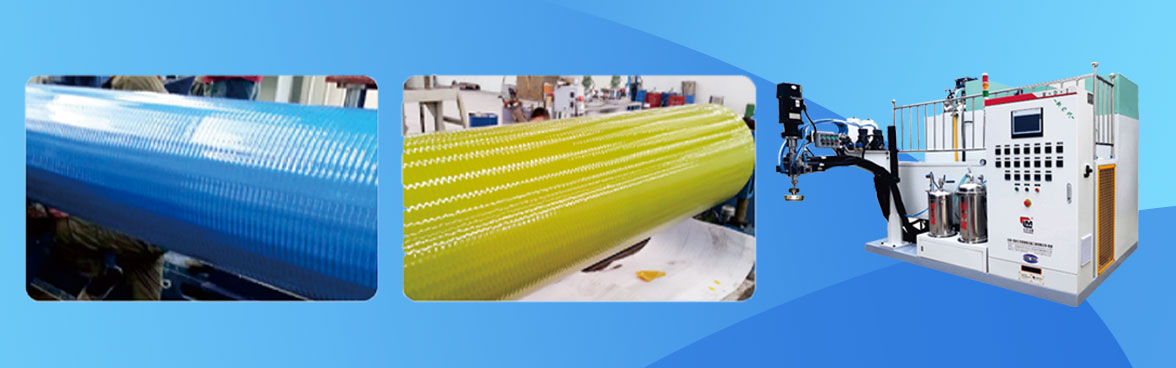

Inside Feilong’s digital workshop, elastomer casting machines are producing elevator wheels with a Shore hardness of 88A. The system achieves a metering accuracy of ±0.5% and maintains material temperature within ±2℃ of the set value. ERP data shows that the same equipment can switch hardness from 83A medical wheels to 95A industrial wheels within two hours. This flexible production capability has shortened delivery times for small-batch custom orders to just 72 hours.

Maintenance logs from a shipbuilding group confirm that Feilong’s automated polyurethane casting system completed 3,000 consecutive casting cycles without failure. Its dynamic mixing technology controls CPU reaction time deviations within ±3 seconds, ensuring wheel density uniformity up to 99.7%.

At Feilong’s National Reaction Injection Molding Engineering Technology Research Center sub-station, engineers are fine-tuning a high-flow elastomer casting machine with an output of 500 kg/min. This equipment integrates a 12-component feed system capable of simultaneous wheel core pretreatment, polyurethane casting, and online inspection. Through its turnkey solutions, Feilong has helped an elevator manufacturer raise its product pass rate from 82% to 99.3%.