According to the 2025 Global Toy Market Research Report, PU (polyurethane) simulation toys — known for their soft touch and superior elasticity — have reached a global market value exceeding USD 20 billion, with an annual growth rate of 35%.

However, manufacturers still face three major challenges: mold wear rates exceeding 15%, color change cleaning taking over 30 minutes, and poor compatibility with eco-friendly raw materials.

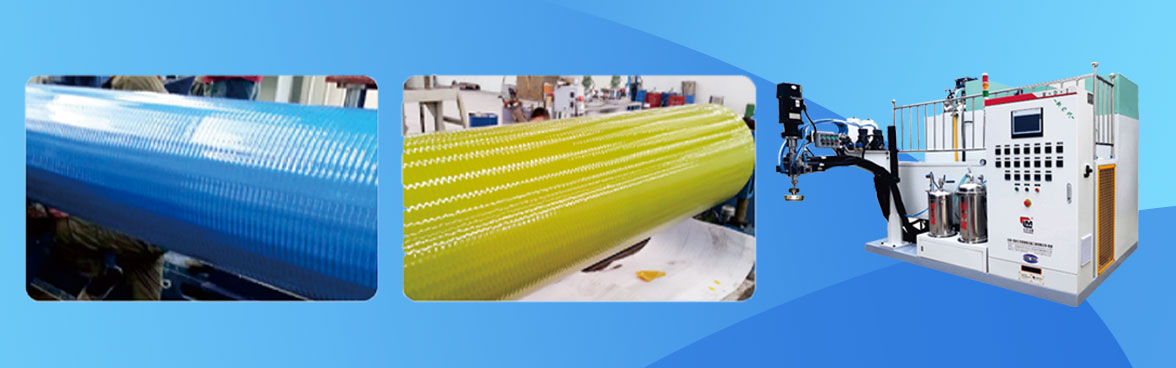

As a national high-tech enterprise, Feilong Polyurethane Equipment has developed its low-pressure foaming machine series featuring precise metering, uniform mixing, and automated control — becoming the key solution to these industry pain points.

Core Equipment: From “Rough Production” to Millimeter-Level Precision

In traditional PU toy manufacturing, even a 2% ratio error in raw materials can lead to inconsistent hardness, while inaccurate mold filling often causes a waste rate exceeding 10%.

Feilong’s low-pressure foaming machine delivers industry-leading performance through three key innovations:

- High-Precision Metering System: Equipped with imported gear pumps and variable frequency drive motors, ensuring a metering accuracy of ≤0.5%, far surpassing the industry average of 1.5%. In PU elastic ball production, this keeps each ball’s weight deviation within ±2 g, raising yield rates above 99%. The dual-spiral pump design maintains stable flow even with high-viscosity materials (up to 2000 CPS).

- Static Mixing Head Technology: The system integrates seven stainless-steel helical units, forming a cut–fold–blend mixing process that achieves 98% mixing uniformity. A simulation food toy factory reported that internal bubble defects dropped from 12% to 3%, while surface smoothness improved to mirror-grade quality — eliminating secondary polishing.

- PLC Intelligent Control System: Featuring a 7-inch touch screen and 100 programmable recipes, it enables one-click formula switching. For example, when changing from chocolate to strawberry-colored simulation cakes, the system automatically adjusts pigment ratios, mixing time, and injection pressure — reducing color-change cleaning time to 8 minutes, improving efficiency by 70% compared with traditional machines.

Materials and Molds: Balancing Eco-Safety and Cost Control

Toy safety and production cost depend on the synergy among raw materials, release agents, and mold design.

Feilong’s integrated solutions tackle two key challenges:

- Eco-Friendly Material Compatibility: The equipment’s 304 stainless steel tank with independent temperature control (±1°C) supports phosphate-free catalysts and water-based blowing agents, ensuring full compliance with environmental standards.

- Lower Mold Costs through Low-Pressure Pouring: Operating pressure ranges from 5–15 bar, enabling the use of aluminum or epoxy resin molds instead of costly steel ones. Feilong’s optimized parting-line design keeps seam width under 0.3 mm, cutting post-trimming time by 60% and overall mold cost by 50%.

Industry Transformation: Redefining the PU Toy Production Chain

As the toy industry faces dual challenges of eco-upgrading and mass customization, Feilong’s innovations offer three major insights:

- Miniaturization for SMEs and R&D Labs: The new micro low-pressure foaming machine, occupying only 1.5 m², integrates tank, pump, and mixer — ideal for startups and small-scale production.

- Smart Manufacturing Acceleration: Equipped with industrial IoT modules, the system uploads real-time data (temperature, pressure, yield rate) to a cloud platform. Managers can monitor operations via mobile app, with automatic alerts for any anomalies.

- Green Manufacturing as the New Standard: The machine’s polyurethane rigid-foam insulation (≤0.022 W/m·K) and waste-heat recovery system reduce total energy consumption by 25% compared to national standards.

From laboratory prototypes to mass production lines, Feilong Polyurethane Equipment is redefining efficiency standards in PU toy manufacturing through its unique combination of precise metering, adaptive technology, and green energy design.

For toy manufacturers seeking high-quality, cost-effective production, choosing the right equipment is not just about efficiency — it’s a strategic move to capture the next wave of personalized consumer demand.