In modern industrial manufacturing, no-mold casting technology is redefining production standards with three major advantages — no mold required, rapid forming, and up to 98% material utilization.

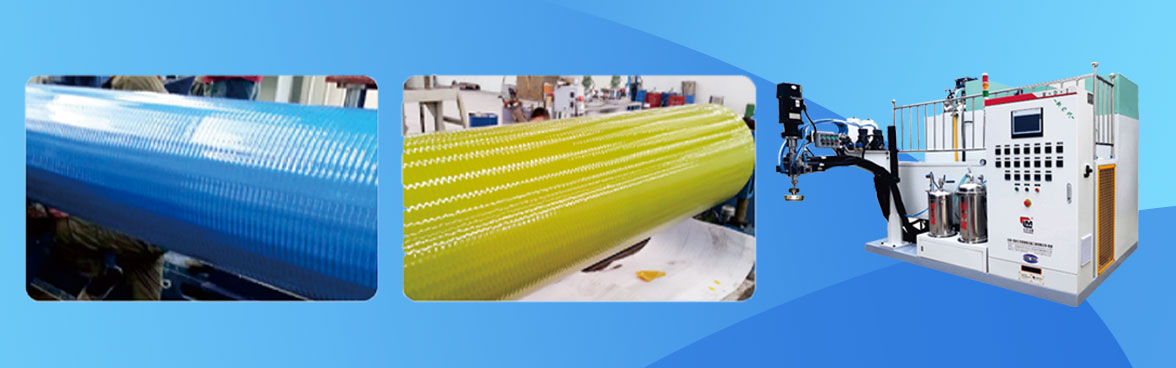

Feilong Polyurethane Equipment’s self-developed no-mold casting system integrates a dynamic metering and mixing platform with rotational forming technology, successfully replacing imported systems and achieving localization breakthroughs across printing, steelmaking, and new energy industries.

1. Core Application Principles

1.1 Material System and Mixing Optimization

Industry-specific formula examples:

- Printing roller (85 Shore A): A component (MDI prepolymer): B component (E-300 chain extender) = 100:15, plus 25% polyether P650 to adjust hardness.

- Steel cold-rolling roller (95 Shore A): A:B = 100:20, with 5% ultra-hard filler to enhance wear resistance by 300%.

Raw material preprocessing:

- Dehydration: Vacuum at 110°C, −0.01 MPa for ≥1 hour.

- NCO content: 6.5 ± 0.2 wt%, batch deviation ≤ 0.1%.

1.2 Equipment Tuning and Process Parameters

- Temperature calibration: A-tank 60°C, B-tank 80°C, pipe 55°C (PID control, ±2°C accuracy).

- Ramp rate: ≤ 5°C/min to prevent thermal degradation.

| Application Industry | Roller Speed (r/min) | Casting Flow (g/s) | Curing Time (min) | Coating Thickness Tolerance |

|---|---|---|---|---|

| Printing roller | 25–30 | 40–50 | 15–20 | ±0.05 mm |

| Cold-rolling roller | 15–20 | 50–60 | 25–30 | ±0.1 mm |

| Food roller | 30–35 | 30–40 | 10–15 | ±0.03 mm |

2. Industry-Specific Technical Solutions

2.1 Printing and Packaging: High-Precision Roller Forming

- Challenges: Surface roughness ≤ Ra 1.6 μm, dynamic balance G2.5 grade.

- Solutions: • Laser closed-loop control for real-time pouring head adjustment. • Stepwise post-curing: 80°C × 4 h, with 2°C/min cooling to relieve internal stress.

2.2 Steel and Metallurgy: High-Wear Roller Production

- Key innovation: • Composite coating with epoxy-glass fiber layer (0.2 mm) to improve adhesion. • Dual-gate top-injection system for smooth metal-polyurethane fusion.

Formula: A:B:C = 100:18:5 (C = MOCA).

Curing: 120°C × 30 min + 80°C × 2 h.

2.3 New Energy Sector: Integrated Airless Tire Forming

- No-mold integrated process eliminates vulcanization molds, cutting cycle time from 2 h to 30 min.

- Bio-based raw material substitution (50% castor oil polyol) reduces carbon emissions by 40%.

Performance:

- Tread hardness: 75 Shore A

- Elongation at break ≥ 400%

- Puncture resistance ≥ 150 N (no rupture)

3. Operational Practice and Quality Control

3.1 Standard Operating Procedure (SOP)

Material preparation:

- PTMG dehydration: 110°C, 0.01 MPa, 1 h (moisture ≤ 0.03%).

- B-component mixing: E-100 → E-300 → MDEA → P650, stirring at 60 rpm for 30 min.

Pouring process:

Vacuum pump (−0.06 MPa) → metering pump → pouring head motion sequence.

If bubbles appear: reduce flow rate 10%, increase roller speed 5 r/min.

3.2 Defect Prevention Manual

| Defect | Cause | Solution |

|---|---|---|

| Bubbles | Moisture > 0.03% | Extend dehydration to 1.5 h |

| Shrinkage | Improper curing gradient | Stepwise cooling 120°C → 80°C |

| Thickness deviation | Laser misalignment | Calibrate daily with gauge block |

| Sand adhesion | Poor coating permeability | Zircon coating 0.8 mm, ≥ 100 cm³/min permeability |

4. Intelligent Upgrades and Future Trends

- AI adaptive control: Industrial cameras monitor coating thickness in real-time, raising product yield to 99.8%.

- Remote IoT platform: 16-parameter live monitoring (vibration, temperature, pressure), > 90% predictive maintenance accuracy.

- Material innovation: Graphene-reinforced nanocomposites (200% wear resistance improvement).

- Eco-friendly materials: Bio-based elastomers reaching 60% renewable content for medical-grade applications.

Conclusion

Feilong’s no-mold polyurethane casting technology—driven by precise metering, dynamic mixing, and mold-free forming—is redefining polyurethane manufacturing standards. From printing rollers to airless tires, it enables cross-industry flexibility, 30% cost reduction, and accelerates China’s transformation toward flexible, intelligent manufacturing.