The mattress manufacturing industry in 2025 is undergoing an unprecedented wave of technological transformation. Feilong Polyurethane Equipment’s newly launched large-scale polyurethane low-pressure foaming machine is redefining industry standards with its ±0.5% raw material ratio accuracy (equivalent to only three slight deviations per 1,000 mattresses) and 98.5% foam density uniformity.

Technical Principle: The Science Behind Precision Control

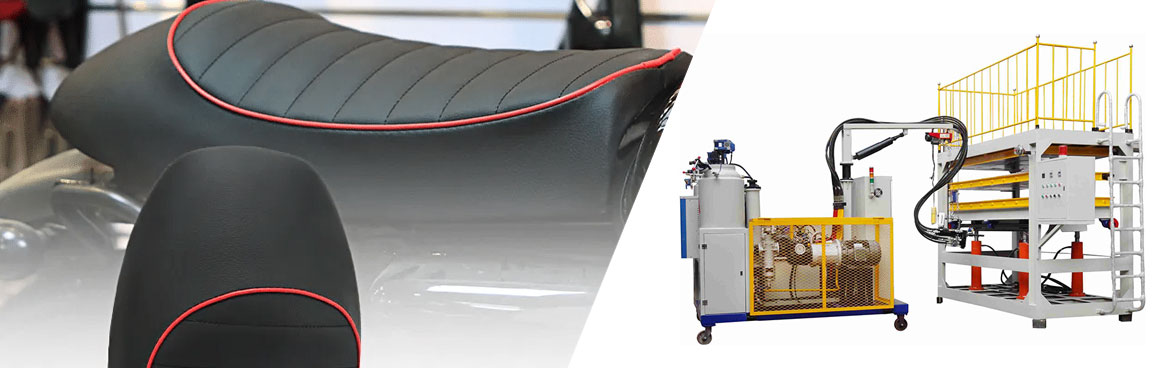

Polyurethane foaming demands nanometer-level control of temperature, pressure, and flow rate. Feilong’s large-scale low-pressure foaming machine establishes a technological barrier through three major innovations:

- Dynamic Mixing Head Technology – The machine features the third-generation Flash-Mix mixing head, equipped with a 2,800–5,000 rpm high-speed stirrer and spiral shear structure, completing micro-uniform mixing within 45 milliseconds. This boosts raw material utilization by 10% and limits foam cell diameter deviation to ±5 μm.

- 5th-Generation PLC Intelligent Control System – Powered by the Omron CP1H PLC, it achieves a 100 Hz sampling frequency and 0.01-second closed-loop control. The built-in database of 100+ mattress formulas supports “one-click product switching,” while IoT connectivity enables remote diagnostics and predictive maintenance.

- High-Precision Metering & Temperature Control – A gear metering pump + servo motor combo ensures seamless flow regulation, maintaining ±0.5% accuracy even when raw material viscosity fluctuates between 2000–6000 CPS. The water bath + infrared heating system maintains ±1°C temperature stability.

Industrial Application: From Lab Data to Factory Efficiency

In a leading mattress factory, six Feilong large-scale foaming machines form an automated line capable of producing 300 mattresses per hour. Compared with traditional systems, labor requirements have dropped by 60%, raw material waste reduced from 8% to 1.2%, and mattress hardness deviation controlled within ±2 Shore.

With the multi-formula management of the PLC system, the production line can switch between products in just 2 minutes. A top mattress brand leveraged this feature to achieve personalized “one-user-one-mattress” customization, increasing order conversion rates by 27%.

The machine also integrates seamlessly with robotic arms and automatic cutting systems, forming a fully automated production workflow.

Performance Advantages: Data-Driven Results

Feilong’s large-scale foaming machine delivers measurable performance gains in four key dimensions:

- Quality Enhancement – 98.5% foam density uniformity ensures 92% rebound retention after 30,000 fatigue cycles, far exceeding the 75% industry average. One listed company reported a 68% reduction in returns and a 96.3 customer satisfaction score after adopting Feilong equipment.

- Efficiency Improvement – Output per unit increased from 80 kg/min to 120 kg/min, and product changeover time shortened from 45 minutes to 5 minutes, raising annual output by 120,000 mattresses per unit.

- Cost Reduction – The machine reduces energy consumption by 18% (saving 120,000 kWh annually) and cuts raw material usage by 10% — equivalent to 3,000 tons of savings per million mattresses produced.

- Automation Integration – The system supports full-process automation, driving both production capacity and operational safety.

Industry Impact: Driving the Future of Mattress Manufacturing

Feilong’s high-precision and large-scale foaming technology empowers both large and medium-sized mattress manufacturers to adopt flexible and customized production models. With rapid mold change and intelligent formula management, even mid-sized enterprises can produce 100+ customized mattress types efficiently, breaking the long-standing equation of “mass production equals standardization.”