Overcoming Industry Pain Points with Material Innovation

Traditional rubber tires have long posed three major challenges for the children's bicycle industry: 38% of parents report air leakage, 27% complain of poor shock absorption, and 19% express concerns about rubber aging and harmful substance release. The emergence of polyurethane (PU) materials has revolutionized this field. With a Shore hardness of 85–95A, PU tires ensure strong surface support and 30% rebound elasticity to absorb road impact. Moreover, they meet EU REACH and EN71-3 environmental standards, with lead and cadmium levels below 0.01%.

| Performance Indicator | Traditional Rubber Tire | Polyurethane Tire |

|---|---|---|

| Abrasion Resistance | Akron wear 0.4 mm³ | Akron wear 0.1 mm³ |

| Puncture Resistance | 15 MPa | 40 MPa |

| Low-Temperature Flexibility | Hardens at -20°C | Remains elastic at -40°C |

| Service Life | 6 months | 36 months |

Core Technologies: Precision Control for Superior Quality

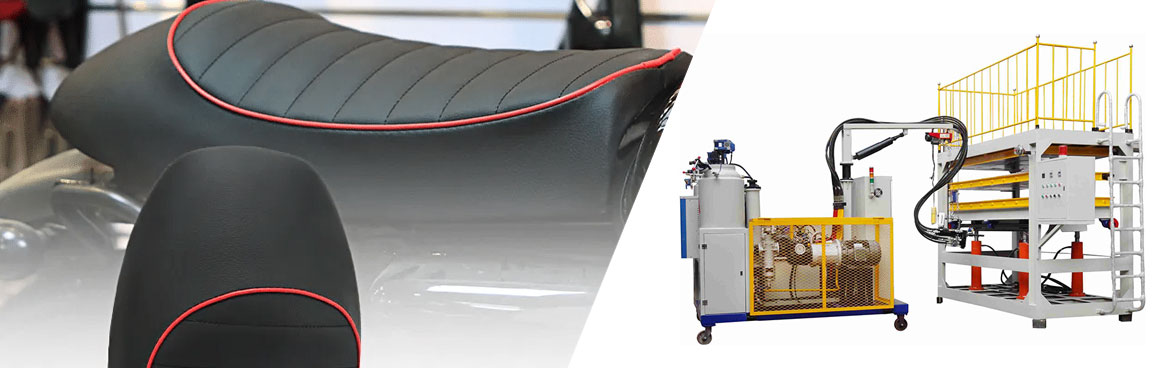

Polyurethane Formulation and Injection Process

The Feilong polyurethane equipment production line is defined by its precision-controlled casting machines. With a variable mixing ratio of 100:8–16 and gear metering pumps offering ±0.5% accuracy, the system ensures precise dosing. The 5000 rpm high-speed mixing head achieves micro-level mixing of prepolymer (A) and chain extender (B) within 0.5 seconds. For 12-inch children’s tires, the discharge rate remains stable at 8–20 kg/min, with each shot deviation under ±1 g—ideal for small, high-precision tire molding.

Mold Design and Temperature Control

Feilong’s modular mold system consists of seven independently replaceable tread modules aligned by 0.02 mm guide pins. Equipped with far-infrared heating plates and a PID temperature control system maintaining ±2°C accuracy, the molds ensure consistent PU curing at 110–120°C. A 0.05 mm vent slot design allows 99% of air bubbles to escape during curing, ensuring flawless tire surfaces.

Automation and Environmental Technologies

The production line integrates an EPR management system for full-process traceability. A 10-inch touchscreen monitors 16 key parameters, triggering automatic alerts when material temperature deviates by 1.5°C. Environmentally, a waste-heat recovery system reduces exhaust gas from 180°C to 60°C, saving 23,000 m³ of natural gas annually and keeping VOC emissions below 15 mg/m³.

Process Innovations: From Detail Refinement to Efficiency Leap

Prepolymer Method and Dual Curing Process

Feilong’s proprietary prepolymer method first reacts polyester polyol with TDI at 80°C to form an –NCO-terminated prepolymer, which is then mixed with MOCA chain extender. This two-step process produces highly ordered molecular chains, raising tensile strength to 45 MPa. The dual-curing process—2.5 hours in-mold followed by 16 hours at 110°C—boosts crosslinking degree from 85% to 98%, resolving PU tire deformation issues.

Quick Mold Change and Flexible Production

To meet diverse specifications of children's tires, Feilong developed a 15-minute quick mold change system. With automatic mold recognition and parameter loading, the same production line can switch among 12", 14", and 16" tires—reducing setup time by 70% compared to conventional systems.

Case Study: Proven Performance Improvements

After adopting Feilong’s PU tire production line, a children’s bike manufacturer achieved:

- Product qualification rate increase from 82% to 99.3%

- Energy consumption reduction from 0.8 kWh/piece to 0.5 kWh/piece

- After-sales complaint rate drop by 82% Additionally, in balance bike production, colorant injection technology enabled simultaneous three-color molding (red/yellow/blue), cutting defect rate to 0.5% and production cost by 18%.

Industry Impact and Future Outlook

As a branch of the National Reaction Injection Molding Engineering Technology Research Center, Feilong has driven industry standardization. The newly developed “Polyurethane Tires for Children’s Bicycles” group standard sets benchmarks for puncture resistance (≥300 N) and aging performance (≥500 hours). Its modular tread design improves recycling rates from 30% to 85%, while Industrial Internet connectivity lifts OEE (Overall Equipment Effectiveness) to 89%—far above the 72% industry average.

In today’s competitive market, technological innovation defines leadership. Through the fusion of precision chemical control and intelligent manufacturing, Feilong Polyurethane Equipment is building a safer, greener, and more efficient foundation for the future of children’s mobility.