Polyurethane elastomer tires represent a next-generation tire technology based on high-performance polymer chemistry. Unlike traditional rubber tires, polyurethane tires are formed through chemical polymerization into a three-dimensional cross-linked structure, combining the elasticity of rubber with the mechanical strength of plastics. Their core material advantages deliver a significant technological leap: Akron abrasion value as low as 0.024m³/1.61KM—5 times better than standard rubber tires; tear strength up to 49 MPa; tensile strength 1.5 times higher than conventional rubber; operating stability from -45°C to 120°C.

Compared with traditional rubber tires, polyurethane tires differ in three dimensions:

- Structural Advantage: Traditional tires rely on air pressure, while polyurethane tires use high-density solid elastomer filling to achieve a puncture-proof, airless design. Puncture resistance is enhanced by over 80%, eliminating blowout risks.

- Performance Matrix: For the same tire size, polyurethane tires can support loads up to 41,200 kg—7 times more than rubber tires. Rolling resistance is reduced by 15.38%, while adjustable hardness between 85–95 Shore A enables a balance between durability and energy efficiency.

- Environmental Benefits: Production eliminates rubber vulcanization, reducing energy consumption by 30%. The material is free from carbon black and aromatic oils, cutting particulate emissions by 60%. End-of-life tires can be recycled into new polyurethane products with over 80% material utilization.

Feilong Technology Breakthrough: From Equipment Innovation to Material Revolution

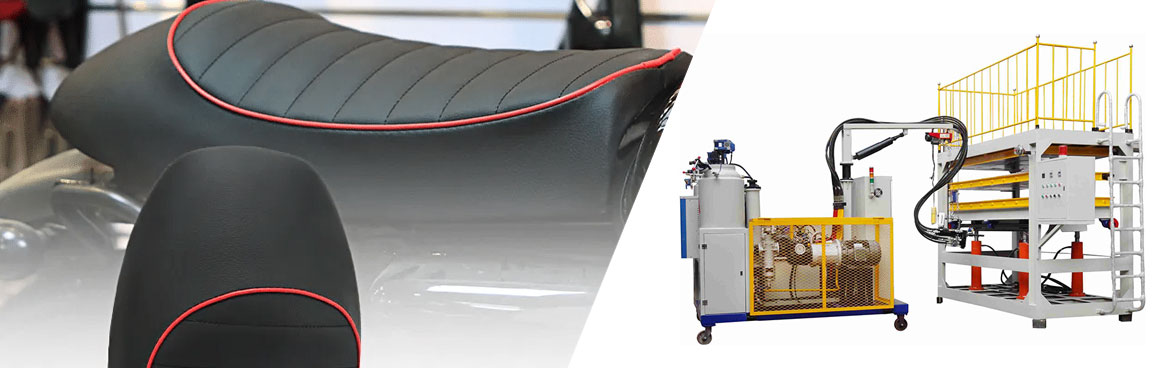

As a core unit of the National RIM Engineering Technology Research Center, Feilong Polyurethane Equipment holds 55 national patents and has reshaped tire manufacturing through a full-chain polyurethane casting innovation:

• Intelligent Casting System

Feilong’s proprietary casting platform uses dynamic refrigerant regulation to maintain ±0.5°C temperature accuracy, ensuring thermal stability of polyurethane elastomers up to 120°C. The system supports 12-component raw material metering and enables 4-hour rapid molding from liquid raw material to finished tire, improving production efficiency by 40% over leading international systems.

• Material Formula Innovation

By adopting nano-modified polyurethane elastomers with bio-based PO3G polyol and CO₂-based polycarbonate diol, Feilong boosts:

✅ Abrasion resistance: +98.43%

✅ Wet grip performance: +73.21%

Successfully solving the tire industry’s long-standing “rolling resistance vs durability vs wet traction” performance paradox.

• Structural Design Engineering

Feilong developed self-sealing puncture-resistant polyurethane layer technology, featuring a gradient hardness tread (90A outer / 70A inner). With 8-ton load capability and 30% vibration reduction, this solves the comfort limitations of earlier polyurethane tire products.

Industrial Applications: From Heavy Equipment to Smart Manufacturing

Feilong polyurethane tires have been engineered for extreme-duty environments:

| Application Area | Performance Advantages |

|---|---|

| Industrial Logistics (AGV & Forklifts) | ≤65dB silent operation, zero floor damage on PVC, 450 kg single-wheel load, maintenance cycle extended from 3 months to 2 years |

| Construction & Mining Equipment | Mine tires withstand 300 rock impacts/day, 8000 running hours—4x rubber tire lifespan; Port crane tires load up to 41 tons; zero blowout downtime |

| Specialty Vehicles | Aerial work platform tires improve 30m height lateral stability by 25%; sanitation vehicles reduce puncture failures by 70%, saving $2000 per year per vehicle |

This material revolution is not only replacing rubber tires—it aims toward “smart tire evolution”, where tires become intelligent data nodes integrating load, pressure, and terrain sensors for Industry 4.0 mobility systems.