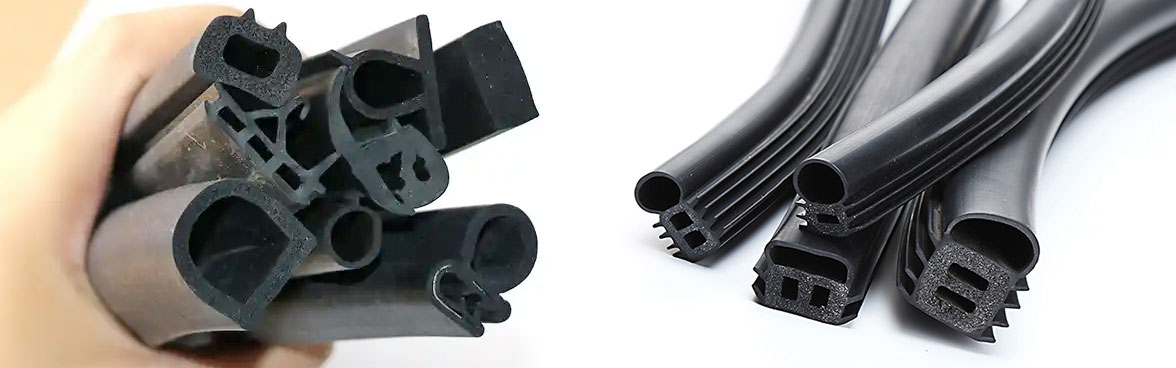

In industrial transmission systems, polyurethane sun gears are widely used for their resilience and adaptability. However, under heavy load conditions, these gears often face deformation challenges caused by stress and elevated temperatures—leading to instability, downtime, and higher maintenance costs.

Feilong Polyurethane Equipment, with over 20 years of expertise, offers a comprehensive polyurethane gear solution that addresses deformation risks through material innovation, structural design, precision processing, and intelligent monitoring.

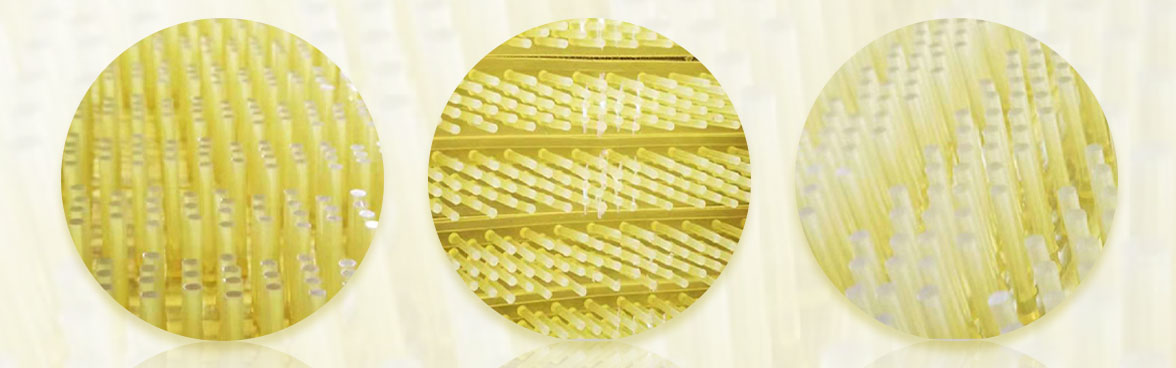

1. Advanced Material Formulation: The Foundation of Anti-Deformation

The root cause of polyurethane sun gear deformation lies in the mismatch between gear material and extreme working conditions. Feilong Polyurethane Equipment tackles this by developing high crosslink-density polyurethane elastomers:

- Achieves tensile strength above 25 MPa (vs. 15–20 MPa in standard PU).

- Provides 40% higher compressive strength, retaining elasticity under constant heavy pressure.

- Incorporates aromatic units to reduce the thermal expansion coefficient to 8×10⁻⁵/°C, ensuring dimensional stability above 60°C.

Case Study: A steel mill’s hot rolling line saw service life increase from 3 months to 12 months under 80-ton loads after adopting Feilong Polyurethane Equipment’s material solution.

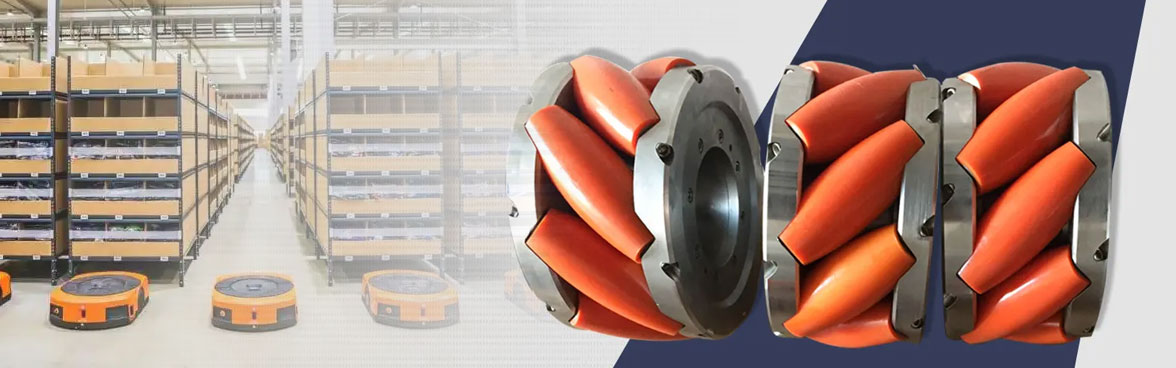

2. Composite Structural Design: Strengthening Mechanical Stability

Feilong Polyurethane Equipment applies multi-layer composite design and biomimetic reinforcement to enhance the durability of heavy load polyurethane gears:

- Dual-layer construction: Inner Shore 70–80A polyurethane absorbs shock, while outer Shore 90–95A polyurethane resists wear.

- Low-friction surface coating: 20–30 μm layer reduces friction coefficient to ≤0.1, tripling wear resistance.

- Biomimetic reinforcement: Radial ribs and wave-section rim designs distribute stress evenly, reduce mass by 15%, and improve dynamic response by 20%.

3. Precision Polyurethane Gear Manufacturing

High-performance polyurethane gears require precision molding to minimize internal flaws:

- High-pressure Reaction Injection Molding (RIM): Ratio accuracy ±0.5%, injection pressure up to 200 MPa, bubble content <0.1%.

- Vacuum degassing: Achieves 99.8% material density, boosting fatigue resistance by 50%.

- Multi-stage aging treatment: Heat cycles stabilize hardness uniformity within ±2 Shore A, preventing local weak spots.

4. Intelligent Thermal Control & Predictive Maintenance

Heat buildup from heavy friction is one of the biggest threats to polyurethane gear performance. Feilong Polyurethane Equipment introduces active cooling and predictive monitoring:

- Micro-channel cooling system: Maintains gear core temperature below 60°C using water–glycol circulation.

- Sensor network monitoring: Collects strain and temperature data in real time; paired with a digital twin model, it predicts deformation trends 72 hours in advance with 92% accuracy.

This shifts operations from reactive maintenance to proactive prevention, minimizing downtime.

5. Real-World Industrial Impact

Feilong Polyurethane Equipment’s heavy load polyurethane sun gear solutions have proven effective across industries:

- Mining conveyor project: Load capacity increased from 50 tons to 120 tons.

- Service life: Extended from 6 months to 24 months.

- Cost reduction: Annual maintenance costs cut from ¥1.2M to ¥350K.

Recognized by the China Polyurethane Industry Association, Feilong’s technology is now an industry reference for durable polyurethane gear solutions.

Feilong Polyurethane Equipment: Core Competitive Advantages

- End-to-end innovation – From materials to monitoring, delivering a closed-loop technical system.

- Custom solutions for heavy load scenarios – Steel plants, mining, and logistics applications.

- Data-backed reliability – All performance validated by third-party testing and industrial case studies.

✅ Conclusion

The challenge of polyurethane sun gear deformation under heavy loads is no longer inevitable. With optimized materials, advanced design, precision manufacturing, and intelligent monitoring, Feilong Polyurethane Equipment delivers durable, high-performance polyurethane gears that reduce costs, extend service life, and improve industrial reliability.