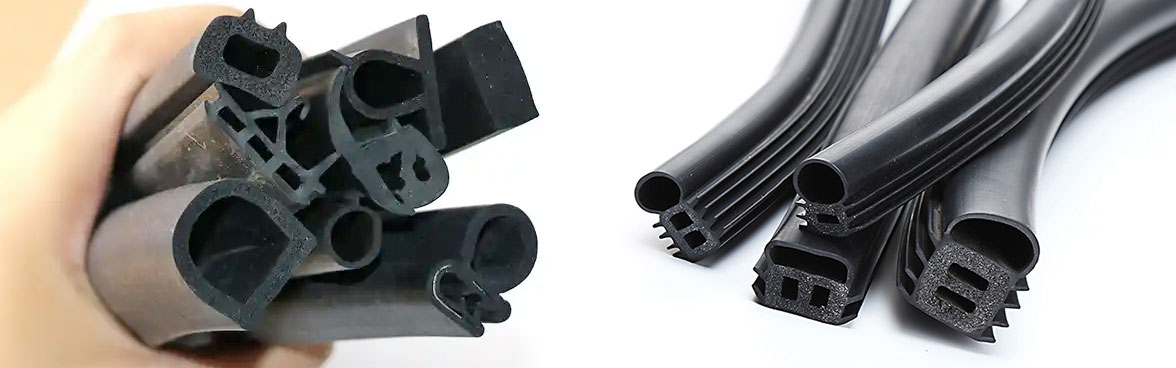

Heavy-duty polyurethane wheels with iron-core design are widely used in logistics, mining, steel plants, and port lifting. Their popularity comes from exceptional wear resistance, load-bearing capacity, and structural stability. However, achieving these advantages depends heavily on polyurethane processing equipment, precision casting technology, and material engineering. By selecting the right polyurethane casting machines, molds, and temperature-control systems, manufacturers can maximize performance and adapt wheels to demanding environments. Feilong Polyurethane Equipment plays a crucial role in this transformation.

1. Equipment–Process Synergy: Enhancing the Core Performance of Iron-Core Polyurethane Wheels

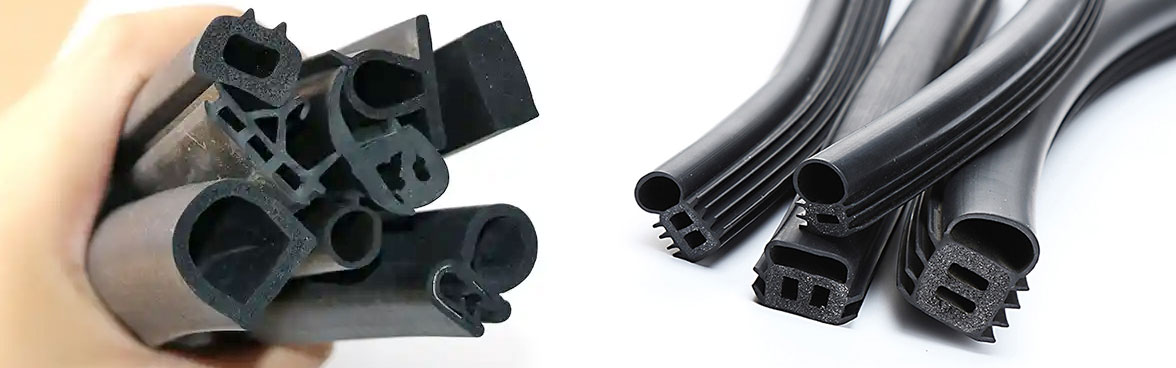

In practical applications, iron-core polyurethane wheels must withstand strict performance requirements:

- Structural stability under heavy loads

- Strong bonding between polyurethane and the iron core

- Excellent wear and tear resistance

- Consistent dimensional accuracy

Feilong Polyurethane Equipment, combined with optimized process design, ensures these key breakthroughs.

(1) High-Precision Polyurethane Casting Machines: Guaranteeing Material Uniformity

- Key Equipment: Feilong high-pressure polyurethane casting machine, PLC-controlled metering and mixing system.

- Accurate mixing of isocyanates (A-component) and polyols (B-component) is critical. A ±1% error can reduce wheel wear resistance by more than 20%. Feilong’s machines use servo-controlled flow to maintain ±0.5% precision. Combined with high-speed dynamic mixing heads (3000–5000 r/min), the result is uniform material dispersion and 30–50% higher durability in polyurethane wheels.

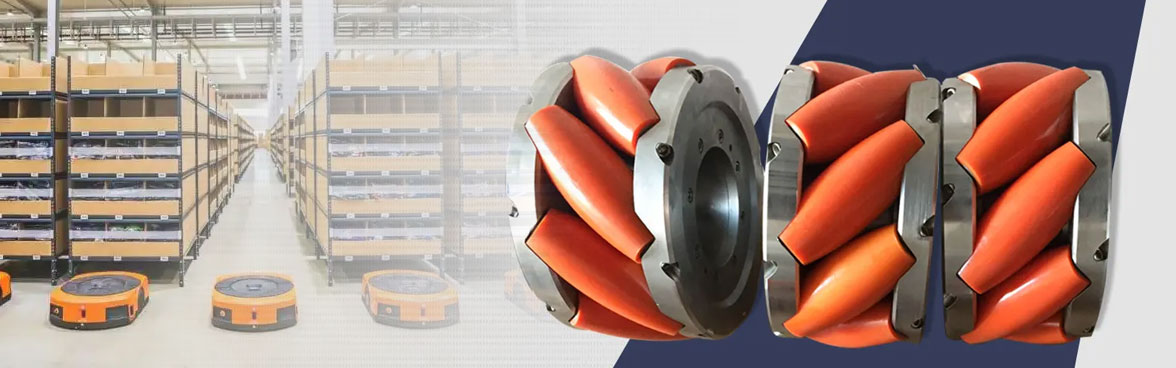

(2) CNC Polyurethane Molds and Temperature Control: Ensuring Dimensional Accuracy

- Key Equipment: Feilong CNC polyurethane molds, mold temperature controllers (accuracy ±1℃).

- Wheel rim thickness and hub curvature must match iron-core load distribution. Feilong CNC molds (precision ≤0.05 mm) guarantee uniform polyurethane coating. Temperature controllers stabilize curing between 60–80℃, reducing shrinkage stress and lowering crack probability to below 1%.

2. Customizable Polyurethane Equipment for Diverse Applications

Different industries require polyurethane wheels with special properties—heat resistance, explosion-proof safety, or extreme wear resistance. Feilong’s customized polyurethane processing equipment ensures wheels meet these demands.

(1) High-Temperature Polyurethane Wheels (Steel Plants, Foundries)

- Wheels must remain stable at 80–120℃ without softening or cracking.

- Feilong’s high-temperature polyurethane casting machines allow precise addition of heat-resistant additives like aromatic polyamide fibers. Extended curing channels (100℃ × 3 hours) promote thermal stability. Heat-aging tests (150℃ × 1000 hours) verify durability, extending wheel life in steel billet transport from 3 months to 6+ months.

(2) Wear-Resistant Polyurethane Wheels (Mining, Gravel Roads)

- Mining and quarry environments demand wheels with 50% higher abrasion resistance.

- Feilong’s enhanced mixing system (8000 r/min) disperses UHMWPE micropowders or ceramic particles evenly into the polyurethane matrix. Abrasive wheel wear tests confirm that service life in mines increases from 1 month to 3+ months.

Conclusion

Feilong Polyurethane Equipment strengthens heavy-duty iron-core polyurethane wheels through three pathways:

- High-precision mixing and casting

- CNC molds and temperature-controlled curing

- Functional customization for heat and wear resistance

From polyurethane casting machines ensuring material uniformity to CNC molds achieving dimensional precision, Feilong integrates equipment with material science for superior results.

With the rise of automation and intelligent polyurethane manufacturing, heavy-duty polyurethane wheels are evolving toward greater durability, safety, and adaptability—offering optimized solutions for logistics, mining, steel, and port industries.