According to the polyurethane foaming equipment industry report, the global high-resilience memory foam market is growing at an annual rate of 12%. However, more than 30% of manufacturers still struggle with molding defects. During the production of cold-cured high-resilience polyurethane foam, four major challenges persist:

- Closed-cell shrinkage causes dimensional deviations exceeding 5%;

- Surface delamination reduces product yield to around 70%;

- Internal voids occur at rates up to 15%;

- Foam collapse leads to a 20% increase in raw material waste.

These issues stem from both the intrinsic reaction characteristics of polyurethane chemistry and the insufficient precision of processing equipment.

Dynamic Ratio Control: The Core of Process Stability

From a chemical perspective, the balance between the crosslinking reaction (polyether polyol with isocyanate) and the foaming reaction (water with isocyanate) must be tightly controlled. If the gel reaction proceeds too rapidly, excessive elasticity in the cell walls forms closed cells that shrink after cooling; if too slow, the foam collapses due to insufficient support.

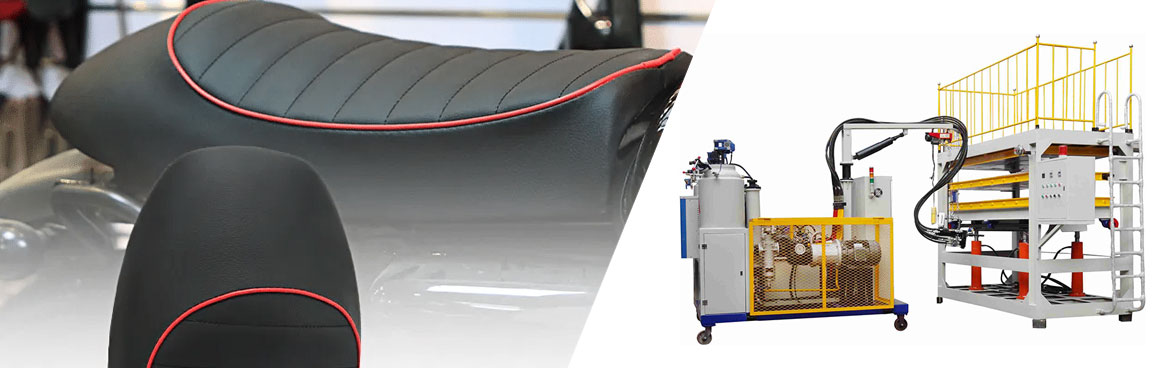

Feilong Polyurethane Equipment addresses this reaction balance through its dynamic ratio algorithm. Utilizing one of its 55 patented technologies—an intelligent metering module—the system achieves raw material ratio accuracy within ±0.5%, outperforming the industry average of ±2%.

The equipment employs high-precision, low-speed metering pumps and acid-resistant stainless-steel tanks with oil temperature control accuracy of ±1°C, maintaining the optimal material temperature of 20–30°C for balanced reactivity.

For various foam densities (45–80 kg/m³), the system automatically adjusts catalyst dosing. For instance, when producing 50 kg/m³ mattresses, the tin catalyst dosage is precisely maintained between 0.003–0.005 parts, preventing over-crosslinking and foam brittleness.

Precision Mixing and Complex Mold Filling

Feilong’s spiral three-stage shear mixing head ensures microscopic uniformity of raw materials. To solve the molding challenges of large and irregularly shaped memory foam products, the foaming machine is equipped with a rotating pouring arm combined with a 3D CNC positioning system, ensuring uniform filling of complex mold cavities.

Intelligent Production and Temperature Control

The ERP-integrated production management system enables end-to-end process control, from raw materials to finished products. The adaptive mold temperature control system, featuring 16 temperature sensors, maintains a temperature difference of ≤2°C between the upper and lower mold plates—crucial for stable foam texture and uniform density.

As a key branch of the National Reaction Injection Molding Engineering Technology Research Center, Feilong incorporates Industry 4.0 concepts into every production line. Its remote diagnostic system continuously collects operational data, using AI algorithms to predict component wear, boosting overall equipment efficiency (OEE) to 85%.

AI Formula Development: The Future of Memory Foam Manufacturing

Experts from the China Polyurethane Industry Association predict that future competition in the high-resilience memory foam sector will center on the integration of digitalized processing and material innovation.

Feilong, in collaboration with the National Technology Transfer Center of the Chinese Academy of Sciences, is developing an AI-driven formulation system that leverages over 100,000 process datasets. This system reduces the new formula implementation cycle from two weeks to just three days, setting a new industry benchmark.

Feilong: A Trusted Partner for Excellence

As the Chair Unit of the Polyurethane Equipment Committee of the China Polyurethane Industry Association, Feilong continues to tackle complex molding challenges with 35 years of expertise. From aerospace materials to household comfort products, its equipment has served over 300 enterprises, enabling the production of more than 200 million high-quality memory foam products.

For manufacturers pursuing premium quality and efficiency, choosing Feilong Polyurethane Equipment is not just a technical upgrade—it’s a strategic investment in the future of the market.