In September 2025, Feilong Polyurethane Equipment officially obtained authorization for its patented foaming equipment featuring an internal cleaning mechanism. This innovation effectively solves the long-standing challenges of raw material blockage and equipment cleaning, improving rigid polyurethane foam filling efficiency by 30%. It marks a major milestone—China’s polyurethane equipment industry breaking the foreign monopoly in high-end production technologies.

Industry Background and Challenges: Balancing High-Performance Filling Needs and Technical Limitations

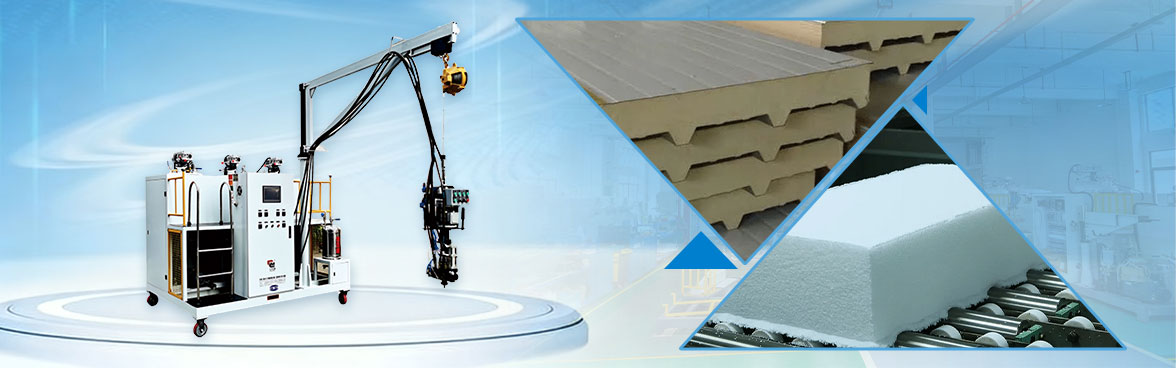

Rigid polyurethane foam plastics, known for their ultra-low thermal conductivity (0.018 W/m·K) and lightweight density (30–60 kg/m³), are widely used in building insulation (65% market share), cold chain systems, and automotive manufacturing.

However, Feilong’s field research revealed that 78% of product defects stem from three key issues:

- Insufficient flowability – leading to incomplete filling in complex molds, with product pass rates below 80%.

- Uneven density – density deviation exceeding ±15% within the same product, affecting both structural strength and insulation.

- Poor adhesion – bonding strength with substrates below 0.8 MPa, causing delamination under vibration conditions.

Technical Methodology: Feilong’s Four-Dimensional Innovation Framework

Feilong Polyurethane Equipment addresses these challenges through equipment, process, material, and quality control innovations—representing the highest level of industrial technology in China.

1. Equipment Optimization: End-to-End Process Reinvention

The dynamic mixing head employs a triple “shear–rotation–vibration” mechanism, achieving mixing uniformity above 98%.

The adaptive pouring system, equipped with a five-axis robotic arm and 0.1 mm-precision flow sensors, reduces filling time for large components by 40%.

The patented internal cleaning mechanism eliminates dead zones, reducing cleaning time from two hours to just 15 minutes.

2. Process Parameters: Intelligent Control for Precision Foaming

The AI-driven process control system continuously optimizes production parameters:

- Raw material temperature control within ±0.5 °C

- Pouring pressure adjustable between 0.5–15 MPa

- Isocyanate index precision up to ±0.02

In automotive filter gasket production, maintaining a 52 °C pouring temperature and 12 MPa dynamic holding pressure reduced compression set deformation from 30% to 15%.

3. Material Formulation and Quality Control

The ultrasonic dispersion technology, co-developed with material partners, reduces pigment particle size to 1–2 μm, ensuring stable color and flow.

The equipment fully supports the HFO-1336mzz(Z) low-GWP foaming agent, with material loss rates below 3%.

Through infrared spectroscopy and X-ray density monitoring, the real-time quality control system shortens defect response time to 15 minutes, increasing large-component yield rates from 72% to 95%.

Application Case: Automotive Filter Gasket—Precision and Efficiency Combined

Feilong’s fully automated pouring line shortened production cycles from 45 seconds to 28 seconds, boosting daily output by 60%.

Dimensional accuracy reached ±0.1 mm, and product yield improved from 75% to 98%.

Meanwhile, raw material loss decreased by 30%, and after-sales claims dropped by 70%.

Technical Advantages and Market Value: From Patents to Industry Standards

As of 2025, Feilong holds 55 patents, including 23 invention patents, and has led the drafting of the “Polyurethane Elastomer Casting Machine” industry standard.

As a branch of the National Reaction Injection Molding Engineering Technology Research Center, Feilong invests 8–12% of annual revenue into R&D.

With a price only one-third to one-half that of imported equipment, Feilong achieved a 28% domestic market share in 2024, maintaining the No. 1 position for five consecutive years.

Outlook and Conclusion

Feilong Polyurethane Equipment is evolving from a machinery supplier into a comprehensive polyurethane solution provider, adhering to its core philosophy:

“Innovation begins with customer pain points, patents build technological barriers, and open collaboration drives application expansion.”

With continuous breakthroughs in intelligent equipment and materials integration, Feilong contributes its “Smart Feilong” technology to the advancement of high-end manufacturing worldwide.