In recent years, polyurethane (PU) materials have been increasingly used in the curtain wall and architectural window industry. Fiberglass-reinforced polyurethane (FRP-PU), rigid PU foam, and PU insulation composites have emerged as groundbreaking materials, surpassing traditional thermal break aluminum in thermal insulation, mechanical strength, and durability. As a Sub-center of the National Reaction Injection Molding Engineering Technology Research Center, Feilong Polyurethane Equipment is leading the industrial transformation through equipment innovation that enables advanced PU applications in architectural systems.

Fiberglass-Reinforced Polyurethane: A Breakthrough in Structural Window Materials

In Feilong’s equipment showroom, a striking comparison instantly reveals the power of materials: traditional aluminum alloys have a thermal conductivity of 237 W/m·K, while fiberglass-reinforced polyurethane achieves just 0.34 W/m·K—1/700 of aluminum. This advantage is the foundation of the PU revolution in curtain walls and window frames.

Using an optimized composition of 20% polyurethane resin and 80% fiberglass and manufactured using advanced pultrusion technology, FRP-PU profiles combine thermal insulation and structural strength in one material.

The mechanical performance metrics highlight its engineering superiority:

| Property | FRP-PU | Traditional Aluminum |

|---|---|---|

| Flexural Strength | 1442 MPa | ~300 MPa |

| Density | 1.7 g/cm³ | 2.7 g/cm³ |

| Thermal Expansion Coefficient | 0.64×10⁻⁵ K⁻¹ | ~2.4×10⁻⁵ K⁻¹ |

The result? Stronger and slimmer window frames, 10% larger daylighting area, and no deformation from thermal expansion or contraction.

Thermal insulation is another winning advantage. With a thermal conductivity of 0.34 W/m·K, FRP-PU combined with triple-pane insulated glass can reduce the overall window U-value to 0.654 W/(m²·K)—far superior to conventional thermal break aluminum systems (2.5–3.0 W/(m²·K)).

Continuous Innovation: Feilong’s Technology Pipeline

Feilong continues to shape the future of polyurethane processing:

- September 2024 Patent Filed: Polyurethane Casting Device with Ultra-Hard Filler This innovation improves the dispersion of ultra-hard fillers to increase wear resistance by 30%, enabling PU profiles for coastal high-salt environments.

- May 2025 Patent Filed: Polyurethane Casting Machine for High-Viscosity Polymers Solves color paste dispersion challenges in high-viscosity elastomers, enabling mass production of colored PU profiles.

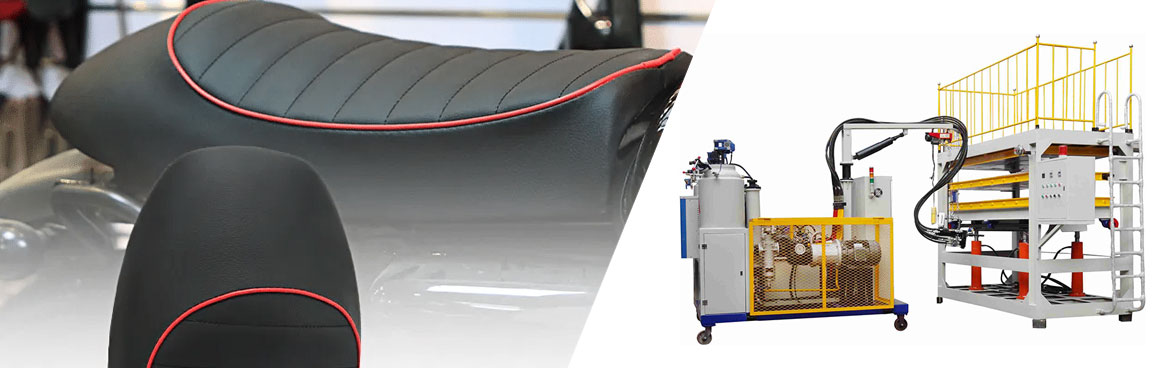

Feilong invests 8–12% of annual revenue into R&D and has built a team where 40% are senior engineers across chemical, mechanical, and control disciplines. In 2023, the company was recognized as a "Zhejiang Provincial Specialized and Innovative Enterprise". Their Fully Automatic Multi-Purpose PU Elastomer Casting Machine, powered by flow compensation control and smart metering calibration, achieves ±0.5% mixing precision, reaching international advanced standards.

Conclusion: Polyurethane Windows Pave the Way for Green Architecture

Feilong Polyurethane Equipment has propelled polyurethane from laboratory research into real-world building applications. Fiberglass-reinforced PU windows are not just a material upgrade—they represent a shift toward energy-efficient, low-carbon architecture. With lightweight strength, superior thermal insulation, and long service life, PU window systems will redefine the value of modern building façades.