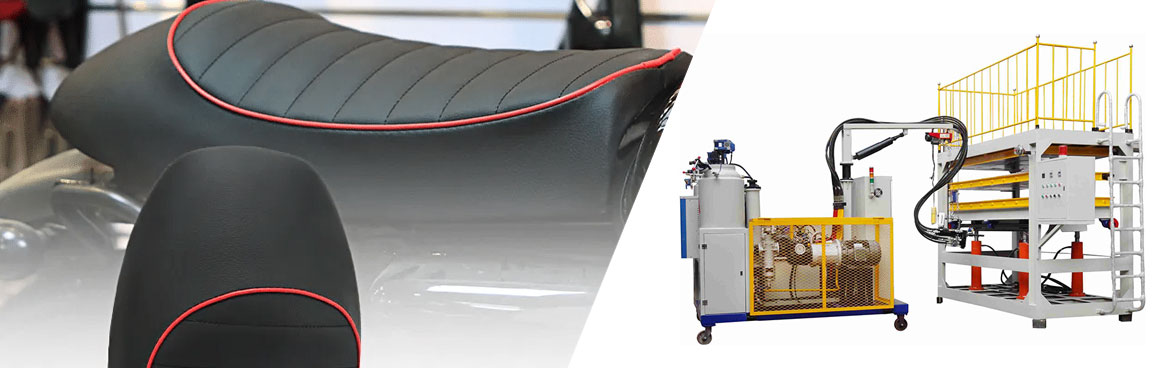

The global manufacturing sector is undergoing a rapid shift toward micro-scale production. When smartphone camera modules demand 0.1mm sealing precision and minimally invasive medical instruments require nano-level density control of cushioning materials, traditional polyurethane foaming systems struggle with excessive output and insufficient precision. Feilong Polyurethane Equipment has launched a Precision Micro Foaming Test Machine that redefines production standards for small, high-precision components with groundbreaking micro-scale engineering capabilities.

Microflow Control Revolution Solves Industry Challenges

Conventional polyurethane foaming systems offer flow control accuracy of only ±5%. While acceptable for large automotive parts such as bumpers, this level of error becomes catastrophic when dealing with micro seals requiring as little as 0.01g of raw material—where a slight deviation can cause product failure. Feilong’s system achieves microflow stability at ±0.5%, equivalent to controlling just 0.005 ml of deviation in a 1 ml injector. This capability has been certified by the National Quality Supervision and Inspection Center for Plastic Machinery.

The system also features advanced dynamic mixing technology with dual-screw asynchronous agitation and real-time pressure feedback 10 times per second. This enables precise molecular-level mixing of A/B components within 0.5 seconds—a performance previously considered unattainable in micro polyurethane applications.

Unlocking Billion-Dollar Micro Application Markets

1. Micro Seals for New Energy Batteries

This system is being used to enhance sealing performance in EV battery packs. Laboratory tests from a leading battery manufacturer show that O-rings produced with this system achieve a compression set of only 8% after thermal cycling between –40°C and 125°C, outperforming the industry average of 15%. This boosts battery sealing from IP67 to IP68, supporting the rise of 800V high-voltage platforms.

2. Electronic Component Encapsulation

In high-frequency 5G modules, precision is critical. The system integrates a CCD vision unit with a six-axis robotic arm, injecting polyurethane material with 0.1 mm positional accuracy into micro cavities as small as 0.5 mm × 0.3 mm. This enables stable high-frequency sealing in millimeter-wave filters and RF components.

3. Medical-Grade Micro Cushioning Components

Feilong’s Gradient Density Foaming Technology enables customizable hardness transition—from Shore A30 to A80—within a 2 mm cushioning layer. In animal trials conducted by a Shanghai-based medical device company, laparoscopic instruments equipped with these cushions demonstrated 40% improvement in operating precision and 62% reduction in tissue trauma.

Reinventing Micro-Scale Manufacturing

Traditionally, developing a micro polyurethane formula required over 200 trial iterations and 3–6 months of validation. Thanks to Feilong’s 100-group parameter memory and cloud-based formula database, the development cycle is now reduced to just 45 days.

As manufacturing enters the era of millimeter-scale innovation, Feilong’s Precision Micro Foaming Test Machine is more than a piece of equipment—it is a strategic driver of micro-manufacturing evolution. From semiconductor packaging to microrobotics and wearable medical devices, Feilong is empowering new industries through micro-level precision.