Categories

Recommended

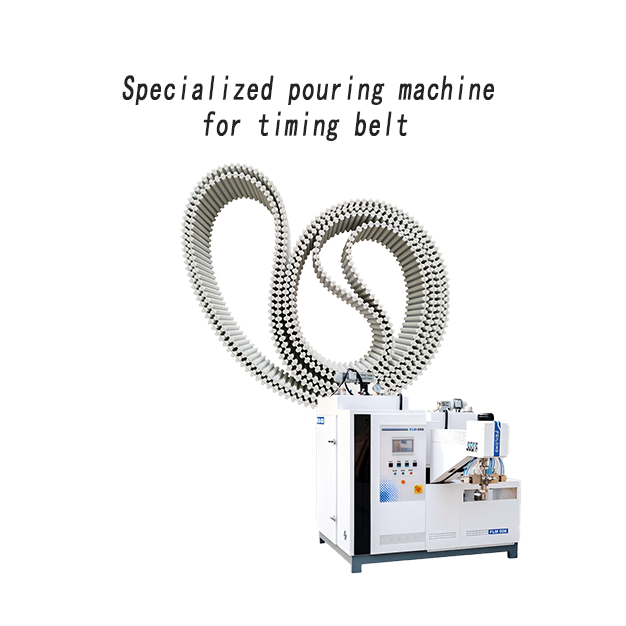

Specialized pouring machine for synchronous belts

By adopting high-precision dynamic mixing and vacuum defoaming technology, and through intelligent control by PLC, a ±1% accuracy in raw material ratio and ±1℃ temperature control are achieved. It is specially designed for the injection molding of polyurethane synchronous belts, ensuring that the synchronous belts have high-precision pitch, excellent linearity, and tensile layer strength.

Product Details

FEATURES

1.The entire system is controlled by a PLC touchscreen, displaying frequency, speed, flow rate, and HMI (Human-Machine Interface), with excellent operability and the ability to store up to 99 recipes.

2.Precise metering: High-precision low-speed gear pump ensures an error rate of ≤5%.

3.Uniform mixing: Equipped with a multi-tooth high-shear mixing head for reliable performance.

4.Casting head: Features a floating mechanical seal to prevent material backflow.

5.Stable material temperature: Utilizes a multi-point temperature control system with thermal oil heating, maintaining an error margin of <±2°C.

6.Bubble-free products: Includes a vacuum degassing system to eliminate macroscopic bubbles.

7.Optional coloring system: Directly injects color paste into the mixing unit, reducing costs and improving efficiency.

END PRODUCTS