First, clarify production demands and product positioning

Product type and application

It is necessary to determine the type of polyurethane products to be produced (such as soft foam, rigid foam, elastomer, etc.), and the equipment corresponding to different types varies significantly. For example:

Soft foam products such as sofa cushions and mattresses require low-pressure foaming machines.

Hard foam insulation boards and decorative lines require high-pressure foaming machines or hard foam molding equipment.

The application scenarios of the product (such as home decoration, furniture, industry, etc.) affect the functional focus of the equipment. For instance, in the furniture industry, the foaming accuracy for comfort needs to be emphasized, while in the industrial field, more attention may be paid to strength control.

Production capacity and size requirements

Capacity planning: Select equipment specifications based on the average daily/monthly output. For instance, small enterprises can choose equipment with lower flow rates (such as 10-50kg/min), while large production lines require equipment with extremely high flow rates (such as over 100kg/min).

Product size: For large-sized products (such as large mattresses), the equipment needs to have a wider pouring range or mold adaptation capability.

Ii. Compatibility of equipment types and technical parameters

Equipment type selection

Foaming machine

Low-pressure foaming machine: Suitable for soft foam products, with low foaming density and good elasticity, such as sofa cushions and memory pillows.

High-pressure foaming machine: It is used for hard foam or semi-hard foam, with high pressure (usually > 10MPa), ensuring more uniform mixing of raw materials. It is suitable for insulation boards and hard foam lines.

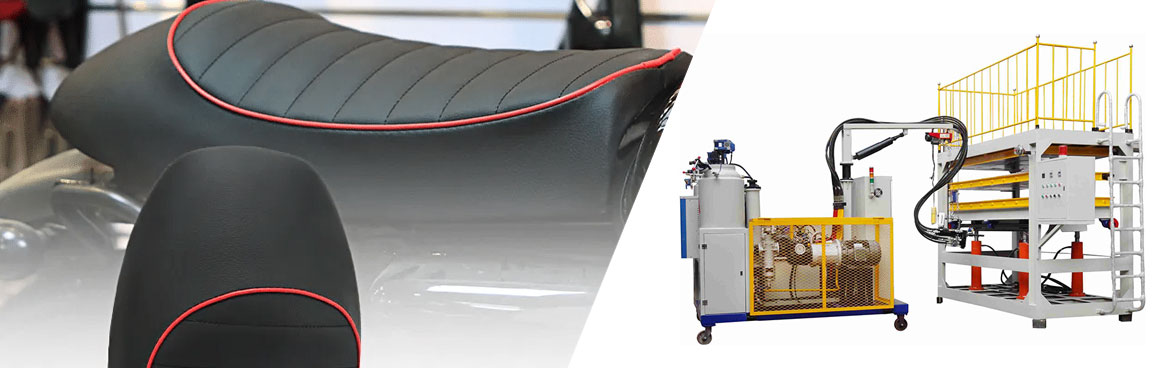

Self-skinning foaming machine: It is used for manufacturing products with hard leather (such as seat armrests), and the equipment needs to have a layer-by-layer foaming control function.

Casting machine/injection machine/molding machine: Suitable for polyurethane elastomers (such as seals, foot pads), it is necessary to precisely control the raw material ratio and casting speed.

Core technical parameters

Measurement accuracy: The error of raw material ratio (such as polyol and isocyanate) should be ≤1%, and high-precision metering pumps (such as gear pumps and plunger pumps) are the key.

Temperature and pressure control: During the foaming process, the temperature fluctuation should be ≤±2℃ (affecting the foaming density), and the pressure control should be stable (for example, the pressure fluctuation of a high-pressure foaming machine should be ≤0.5MPa).

Mixing efficiency: The design of the stirring head (such as dynamic mixing head, static mixing head) affects the uniformity of raw materials. Hard foam products require a higher mixing intensity.

Iii. Raw Material Adaptability and Process Flexibility

Raw material compatibility

The equipment needs to be compatible with different types of raw materials (such as polyether polyols, polyester polyols, MDI/TDI and other isocyanates), paying attention to the viscosity of the raw materials (high-pressure pumps are required for high-viscosity raw materials) and reactivity (fast curing raw materials require fast equipment response speed).

Supports precise metering of multi-component raw materials (such as catalysts and flame retardants added), and some equipment needs to be equipped with multi-component material tanks and conveying systems.

Process adjustment capability

The foaming density can be adjusted (such as soft foam density 20-80kg/m³, hard foam density 30-300kg/m³) and foaming ratio to meet the requirements of different products.

Support customized process parameter storage (such as preset ratios, temperatures and pressures for different products) to enhance production change efficiency.

Iv. Capacity Efficiency and Automation Level

Production efficiency

The equipment cycle period (such as foaming - demolding time) affects production capacity. Equipment with a high degree of automation (such as fully automatic pouring lines) can achieve continuous production.

Multi-station design: Supports simultaneous operation of multiple molds, suitable for mass production (for example, a sofa cushion production line can be equipped with 6-8 mold stations).

Automation and Intelligence

PLC control system: Supports real-time parameter monitoring, fault alarm and data recording, facilitating production management.

Human-machine interface (HMI) : The operation interface is simple and clean, supporting formula import and export, reducing the difficulty of manual operation.

Interlocking function: It can be interlocked with the mold heating system and the material conveying system, reducing manual intervention.

V. Cost Budgeting and Full Life Cycle Cost

Initial procurement cost

Equipment model and configuration affect price: high-pressure foaming machine > low-pressure foaming machine, fully automatic production line > single machine equipment.

Additional function costs: Customized material tanks, environmental protection treatment systems, remote monitoring modules, etc. require additional investment.

Operation and maintenance costs

Energy consumption: The energy consumption differences of motor power and heating systems (electric heating/oil heating), and the power consumption of high-voltage equipment is usually higher.

Replacement of vulnerable parts: The lifespan and replacement cost of components such as stirring heads, seals, and metering pumps;

Maintenance convenience: Whether the equipment structure design is convenient for cleaning (such as detachable mixing heads), maintenance, and reducing downtime.

Vi. After-sales Service and Technical Support

Supplier service capability

Warranty period: Usually 1-2 years. It is necessary to clearly define the warranty scope of core components (such as pumps and control systems).

Maintenance response: Whether 24-hour technical support and on-site maintenance services are provided. For remote areas, the coverage of services needs to be confirmed.

Training and technological upgrading

Does the supplier provide operation training (such as equipment debugging and troubleshooting) to ensure that employees are proficient in using it?

Technical iteration support: Whether software upgrade and process optimization suggestions are provided to adapt to new materials or new standards.

Vii. Environmental Protection and Safety Compliance

Environmental protection requirements

The equipment must comply with local environmental protection standards, such as the control of VOCs (volatile organic compounds) emissions (the production of rigid foam may use Freon-based foaming agents, and environmentally friendly alternatives such as CO₂ and pentane should be selected).

Waste treatment: Raw material leakage collection system, waste foam material recovery device, reducing environmental pollution.

Safety design

Pressure overload protection: Equipped with safety valves and pressure sensors to prevent the equipment from operating under overpressure.

Explosion-proof measures: The electrical system must comply with the explosion-proof grade (such as Ex d) to avoid potential safety hazards caused by raw material leakage.

Emergency stop button: Facilitates rapid shutdown in case of emergencies and ensures the safety of operators.

Viii. Brand and Case References

Brand reputation

Give priority to well-known brands in the industry (such as Hennecki from Germany, Camprooni from Italy, and Feilong Polyurethane Machinery Equipment from Wenzhou, China, etc.), as the stability of the equipment and technical support are more guaranteed.

Check the brand's market share in the furniture industry and avoid choosing unpopular models from niche brands (which may face a shortage of accessories).

Actual case research

Ask the supplier to provide production cases of similar products (such as sofa cushion production lines, mattress equipment), and conduct on-site investigations of the equipment operation effects.

Understand user reviews: Pay attention to real feedback such as device durability, failure rate, and satisfaction with after-sales service.

Summary: Suggestions for the decision-making process

1. Clarify the product type, production capacity and raw materials →2. Screen the suitable equipment type and technical parameters →3. 1. Compare supplier solutions with costs →4. Inspect after-sales service and cases →5. Comprehensively assess environmental protection, safety and long-term benefits. Through systematic analysis, the risk of equipment selection can be minimized to the greatest extent, and production efficiency and product quality can be improved.