Kategori

Disyorkan

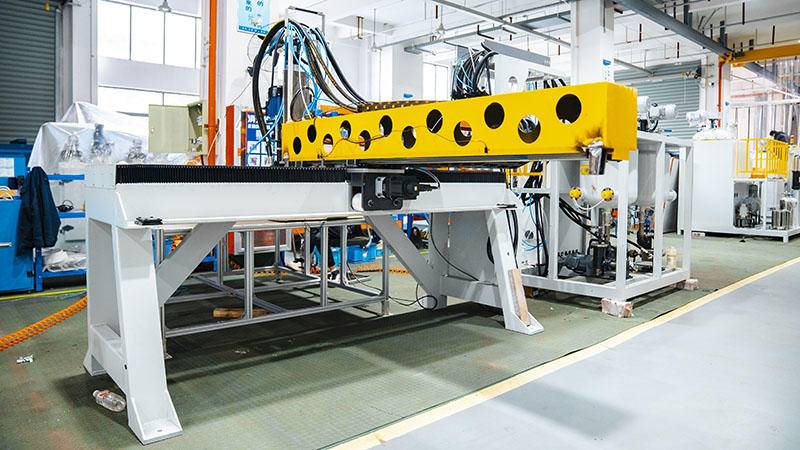

Mesin busa tekanan rendah yang dituangkan secara automatik Mesin busa pencampuran berterusan Busa keras PU / busa lembut / busa khas, dll.

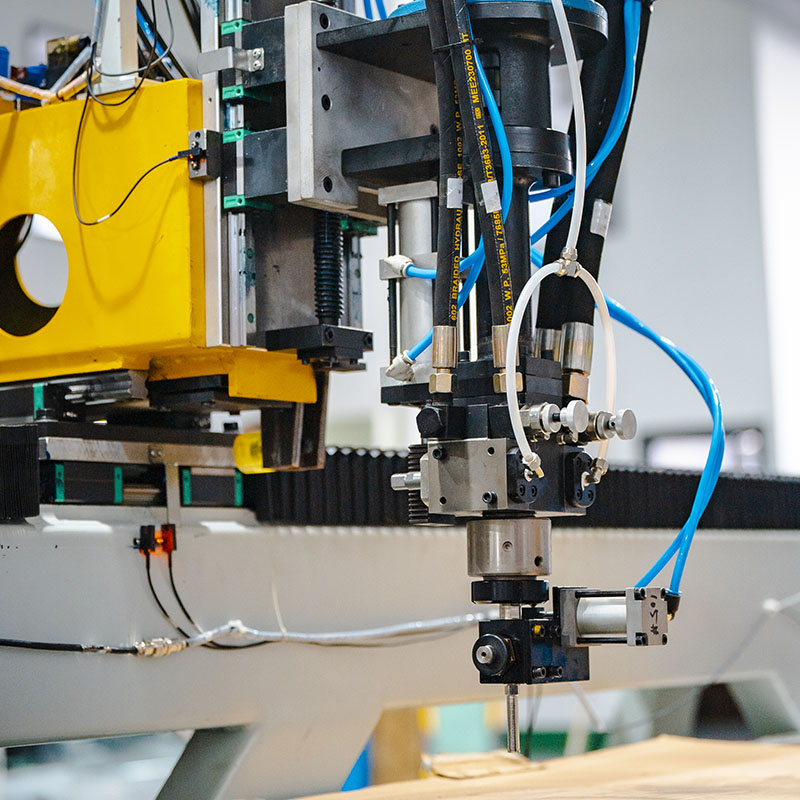

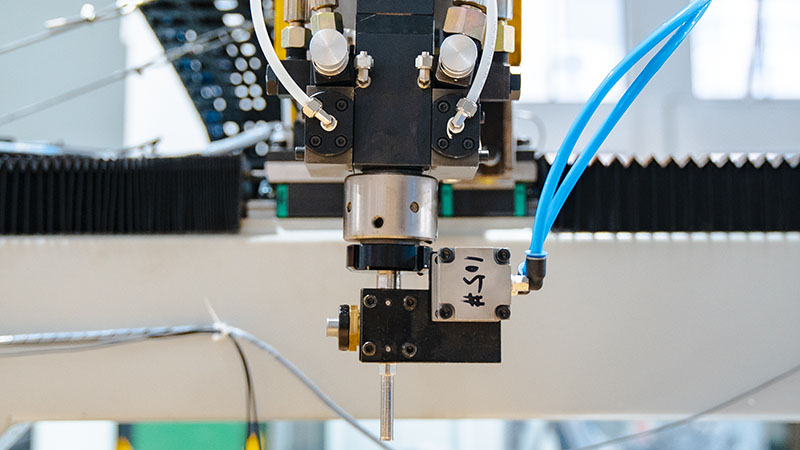

Core selling points: ✅ Intelligent automatic control: PLC + touch screen human-machine interaction, preset process parameters, one-click start of pouring, reducing manual intervention ✅ Low pressure high precision filling: 0.5 - 3 bar low-pressure injection, avoiding bubble formation, finished product porosity < 1% ✅ Two-component dynamic mixing: self-cleaning mixing head, measurement error ≤ ±1%, specially designed for RIM process ✅ Temperature control system: constant temperature management for two-component raw materials (temperature control accuracy ±1℃), suitable for PU/EP and other materials ✅ High efficiency and energy saving: closed-loop pressure control, energy consumption reduced by 30%, daily production capacity up to 200 - 500 mold cycles

Butiran Produk

Spesifikasi teknikal

Jumlah suntikan: 50 - 2000g / s (boleh disesuaikan)

Tekanan kerja: 0.3 - 3 MPa

Nisbah pencampuran: 1: 1 hingga 1: 10 (bahan AB boleh disesuaikan dengan bebas)

Bahan yang terpakai: Poliuretana (PU), resin epoksi (EP), silikon, dan lain-lain.

Kuasa mesin keseluruhan: 5kW - 15kW (bergantung kepada model)

Tahap perlindungan: IP54 (tahan debu dan tahan semburan)

Senario aplikasi:

▸ Industri automotif: busa kerusi, komponen dalaman, pad penebat bunyi

▸ Industri peralatan rumah tangga: lapisan penebat peti sejuk, cincin keseimbangan mesin basuh

▸ Industri bahan pembinaan: perabot kayu tiruan, garis hiasan

▸ Industri pembungkusan: pembungkusan cushioning instrumen ketepatan

Sokongan Perkhidmatan

⚙️ Penyediaan percuma latihan debugging proses

⚙️ Sokongan untuk penyelesaian disesuaikan OEM / ODM

⚙️ Penghantaran logistik global

Nota: Pilihan mengikut keperluan pelanggan - sistem pautan lengan robot / sambungan data MES / konfigurasi bukti letupan

END PRODUCTS